Flexo Printing Machine Manufacturer

- Ceramic Anilox cylinder, long life, wear resistance, corrosion resistance

- 360-degree registration adjustment

- Automatic web guiding system

- Optional video inspection system

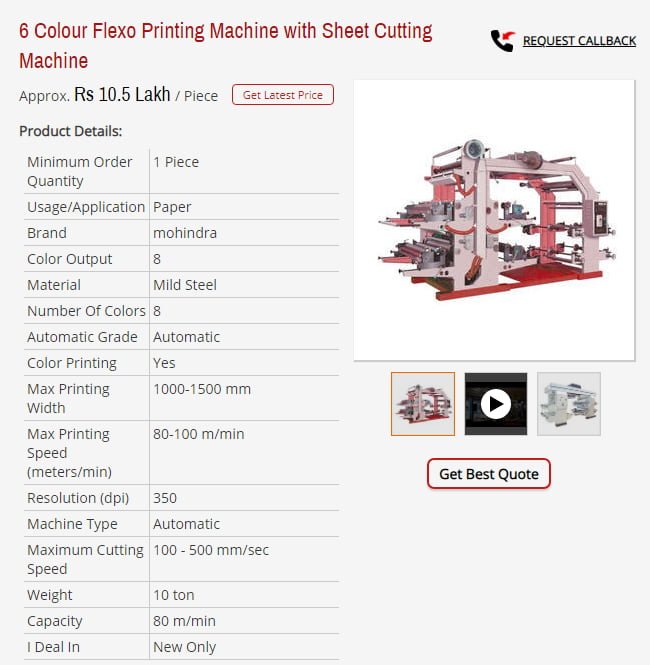

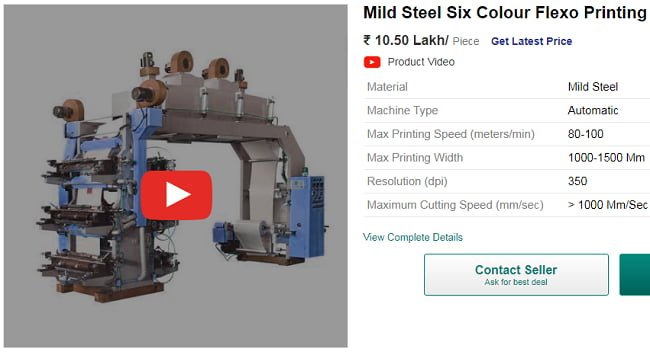

Flexo Printing Machine

Jota flexo printing machine was initially designed for printing graphics, logo.

Many kinds of substrates could be supported, such as paper, film, label.

Please contact us to design and customize your own flexographic printing machine.

Mexico Client Purchased Flexo Printing Machine from Jota

Jota Machinery: Professional Flexo Printing Machine Supplier in China

Jota is original flexo printing machine manufacturer, you could directly video call with us via WhatsApp.

We could lively show you Jota real-time factory and Jota flexo press demo.

Please speed up your hands to send us an inquiry, enjoy a real-time demo with us.

Jota CNC Center

Machining Material

- Visible high-quality components.

- Famous brands such as Siemens, Yaskawa, Delta, Schneider, Mitsubishi.

- Self-supporting CNC processed sheet metal, precision parts.

- Assembly raw materials provided by long-term cooperation suppliers.

Installation and operation user manual, wire connection diagram, tension controller guide.

Installation and operation video tutorial.

One-on-one remote video call assistance.

On-site installation and operation guidance.

- Focus Factory

- Dear Customer

- Professional Team

Around 30-45 days, mainly depends on machine type.

Sure, it is our honor to work for you.

We will offer you some parts as backup, in case any part is broken within one year, we will sent you for free.

Sure, if we have client in your country, we will offer.

Why Jota Flexo Printing Machine

Last update time:18/08/2022

Flexo printing machine is always a great choice for label, paper, film printing, due to its high-quality printing effect together with fast speed productivity.

Besides, the flexo printing machine also has many other pros, these pros attract many clients’ interest.

Compared with gravure, offset and letterpress printing, flexographic printing has its own distinctive characteristics:

Jota Flexo Printing Machine

- Low cost

Compared with gravure printing presses, and corresponding offset printing presses, the price of flexographic printing presses is much lower.

- High integration

The flexographic printing press integrates multiple processes such as printing, die-cutting, and polishing.

Multiple processes could be completed at one time, no need to separately purchase corresponding post-press equipment, a high return on investment could be realized.

- Simple equipment

The equipment structure is relatively simple, and the operation is relatively simple and convenient.

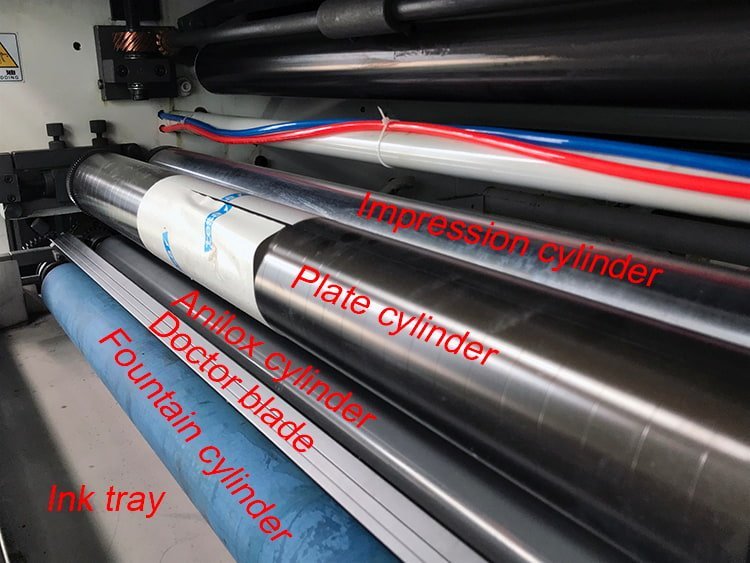

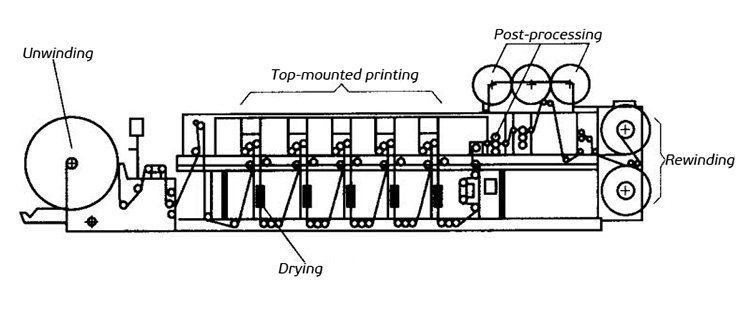

Side View of Jota Flexo Printing Machine

- High efficiency

Flexographic printing uses roll materials, it could not only realize double-sided printing, but also complete in-line polishing (or laminating), hot stamping, die-cutting, waste discharging, and rewinding.

It greatly shortens the production cycle, saves manpower, material, and financial resources, reduces production costs, and improves economic efficiency.

- Wide application range

A wide range of materials is supported, such as paper, plastic film, aluminum foil, adhesive paper, and so on.

- Good quality

Printing quality is good, accuracy could reach 150 lines per inch, and the printed substrate is rich in layers, bright in color, and good in visual effects.

It is especially suitable for packaging material printing.

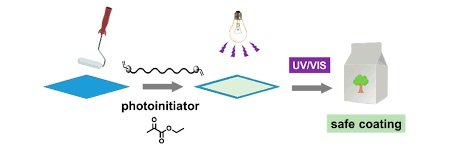

- Environmental protection

New water-based inks and solvent-based inks are used, they are non-toxic and pollution-free, fully comply with the environmental protection requirements, and could also meet the food packaging requirements.

The flexographic printing machine’s cost is only 10% -20% of gravure, the ink consumption is 1/3 less than gravure, the power saving is 40%, and the reject rate is only 1%-2%, which is lower than gravure and offset printing, thereby reduces production costs.

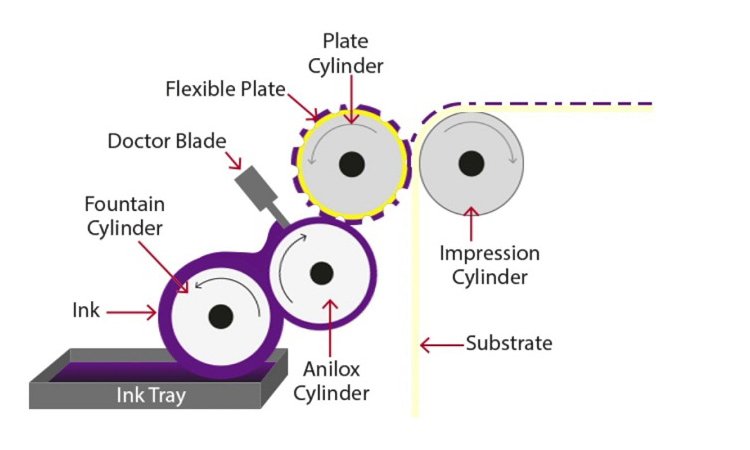

After learning the flexo printing machine’s pros, you could check the following photo to understand the working basis, understanding this will be much helpful for you during your procurement process.

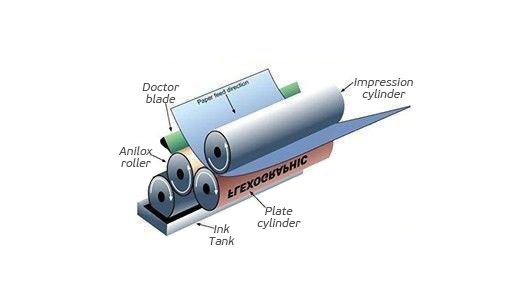

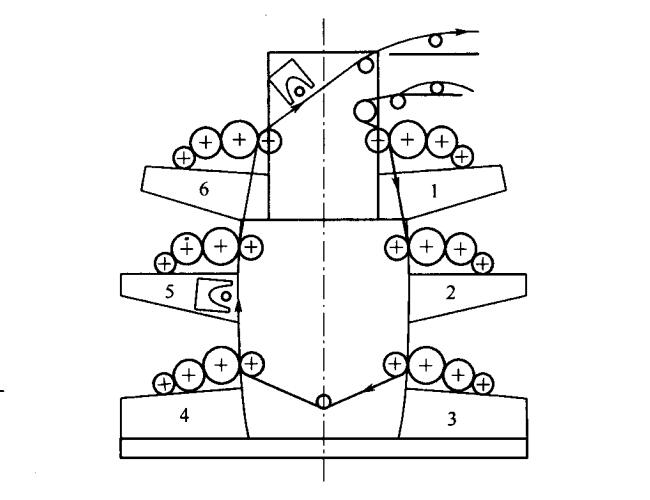

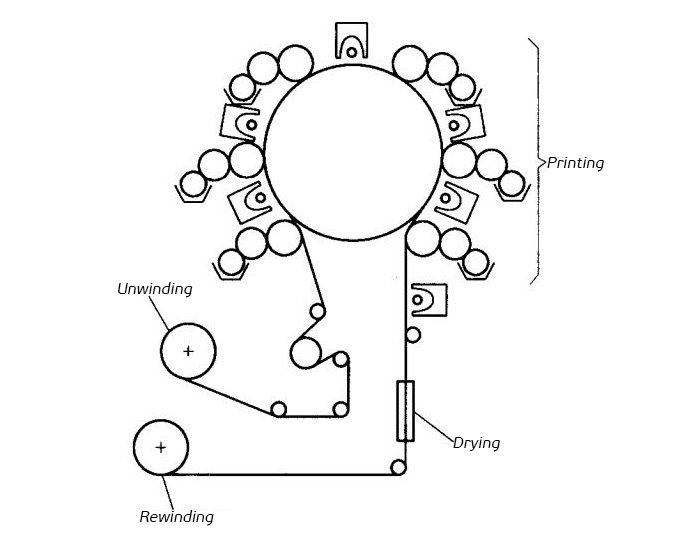

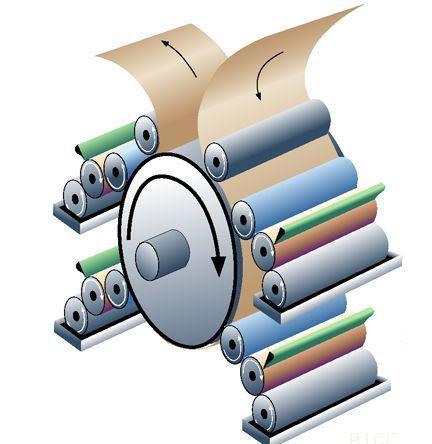

Flexo Printing Machine Working Basis

Water-based ink is initially poured into the ink tray when the flexo printing machine is in working status.

Ink is transformed from a fountain cylinder to an anilox cylinder, then to a plate cylinder, and finally printed on the substrate between the plate cylinder and impression cylinder.

Anilox cylinder is the flexo printing machine’s core component, it is similar to a human being’s heart.

A human being’s heart is responsible for transporting blood to the human body’s every corner, an anilox cylinder is in charge of transporting water-based ink to the printing plate.

Anilox quality defines the ink transporting quality, further influences the final printing quality.

With flexo printing technology’s development, the current anilox cylinder is mainly ceramic type, long life, wear resistance, corrosion resistance, reduces the replacement times, highly improve the printing efficiency.

The other factor that needs to consider when purchasing a flexo printing machine is the ink drying unit.

There are mainly 2 kinds of drying way, one is infrared drying, the other is UV drying.

Relatively speaking, infrared drying is more widely used, but if you need to print on plastic film material, it is better to use oil-based ink plus a UV drying unit.

Of course, there are many other important components in flexo printing machine.

In order to fully understand the flexo printing machine or flexo printing process, it is better for you to build a connection with a reliable flexo printing machine manufacturer.

Please speed up your feet to send us an inquiry, we are worthy of your trust.

Flexo Printing Machine Ultimate FAQ Guide

Flexography

Flexography history

Flexography has a history of 100 years, and flexography’s exact release date is unclear.

Some sources say that flexography originated in Germany, and some sources say that it originated in England in 1890.

But in fact, the first recognized flexography printing press was developed by the British man Howey in 1905, and his invention was granted No. 16519 British Patent in December 1908.

Based on this, flexography has 100 years of history.

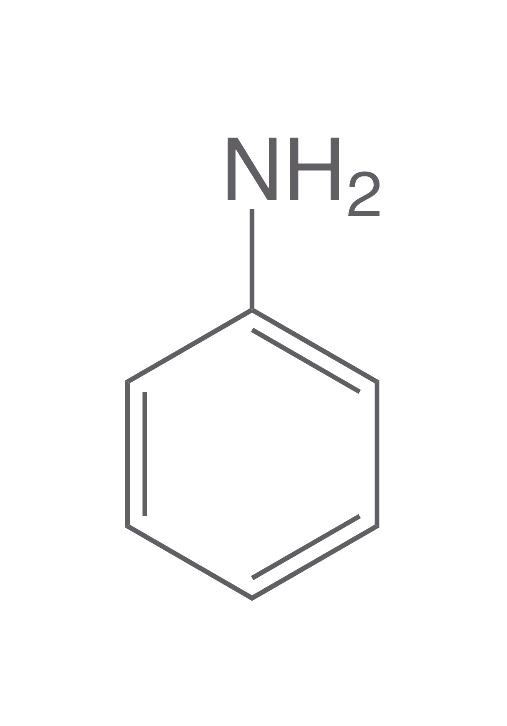

Flexography was first called aniline printing.

The dye used was an aniline dye extracted from coal tar.

The aniline dye was dissolved in alcohol, so it was called aniline printing.

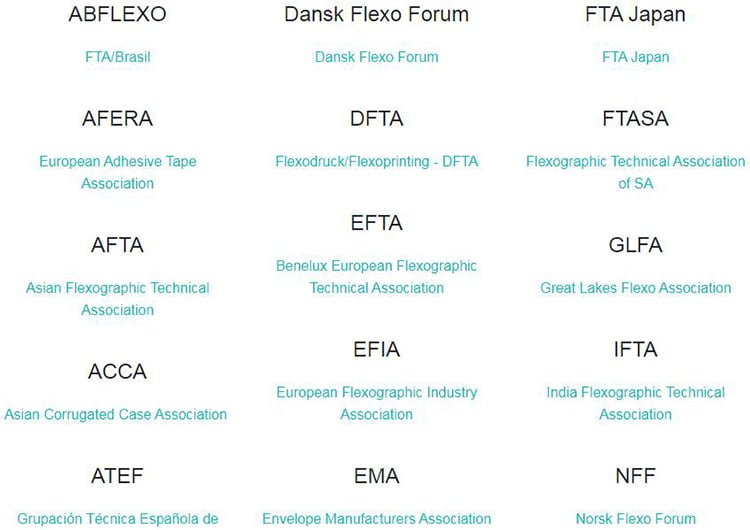

On October 22, 1952, at the 14th Academic Symposium of the American Packaging Industry, aniline printing was renamed flexographic printing;

And in 1958, the Flexographic Printing Technology Association, or FTA for short, was founded;

In 1973, Europe also established the Flexographic Printing Technology Association, which was later recognized by the world’s printing industry.

The Flexographic Printing Technology Professional Committee of the China Printing Technology Association was established in June 1992.

The committee is affiliated with the Shanghai Institute of Printing Technology.

In 1973, the China Flexographic Printing Technology Professional Committee joined the American FTA organization.

And in March 1997, it joined the World Flexographic Printing Technology Association.

Flexography advantages and disadvantages/pros and cons

There are many reasons why companies and businesses choose flexography printing machines.

Flexography printing machines include a broad range of benefits.

- Flexography printing machines allow you to print a large number of products at a fast rate.

Even though the press setting up time may be a little long, the faster production benefit makes up this small drawback.

- Flexo printing machines are also eco-friendly.

As businesses, we have to make sure we play our part in protecting the environment.

- Flexographic printing machines allow you to control the energy consumption during the drying process.

It will then help you to prevent energy waste and high energy bills.

- Flexographic printing machines are the most cost-effective option.

Since flexographic printing machines are long-lasting, you will benefit from lower maintenance costs.

- Flexo printing machines are fully automated.

This even includes its post-printing processes, such as laminating, die-cutting, and varnishing.

This benefit guarantees the entire printing process to be smooth and continuous.

And it gives you more time to take care of other crucial tasks.

So, what is the flexography printing machine’s disadvantage?

A flexo press is complex equipment that requires a regular maintenance schedule.

If not, you run the risk of losing earnings during its downtime.

Flexography examples

Please check the following photo to better understand flexography printing examples.

Flexography uses/applications

According to the application field, flexography printing machines are divided into five categories:

- Labels

- Flexible packaging

- Hard packagings such as cartons and cups

- Carton pre-printing

- Book printing

1. Label

Mainly used in self-adhesive label printing.

This type of flexo printing machine has complete functions, including almost all optional functions, such as:

- Peeling and laminating

- Flipping

- Hot stamping

- Laminating

- Varnishing

- Die-cutting

- Waste Discharging

- Embossing

- Sheeting

- Slitting

- Online Tagging

2. Flexible packaging

Such flexo printing machines are mainly used for printing paper packaging materials, such as:

- Disposable medicalg bags

- Tea packaging paper

- Food packaging paper

- Non-woven fabrics

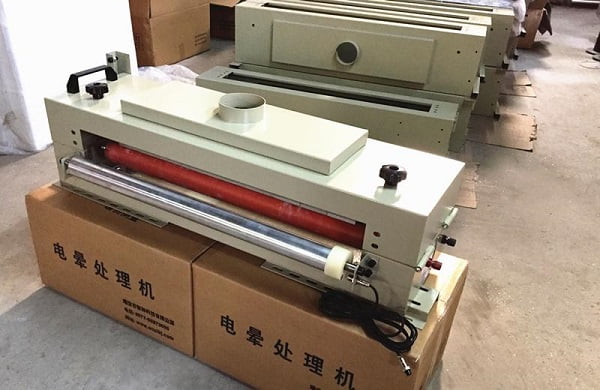

If equipped with a corona treatment device, BOPP, PET, and other plastic films can also be printed.

3. Paper boxes, paper cups

Mainly used in the single and double-sided PE paper, cardboard printing, such as:

- Paper cups

- Paper bags

- Food packaging boxes

- Medicine packaging boxes

4. Carton pre-printing

Mainly used in the large-volume packaging cartons’ pre-printing, such as Tsingtao Brewery.

5. Book printing

Front and back 2 sides printing plus folding, one-time completion.

Flexography Printing

- What does flexographic printing mean?

- How does flexography printing work?

- What is flexography printing used for?

- What substrates could be used for flexo printing?

- Flexo printing technology

- Flexo label printing

- Flexo film

- Flexo textile printing

- UV flexo printing

- Plate mounting flexo printing

- Digital flexo printing

- Flexo printing VS gravure printing

- Flexo printing VS digital printing

- Flexo printing vs letterpress

- What is the difference between litho and flexo printing?

- What is the difference between offset and flexo printing?

What does flexographic printing mean?

Flexographic printing, or flexo printing for short, is one of the most popular forms of industrial printing.

It helps you to print a large volume of high-quality packaging materials and labels.

You could print logos, images, and graphics on a wide range of substrates, such as paper, corrugated board, films, and other more.

How does flexography printing work?

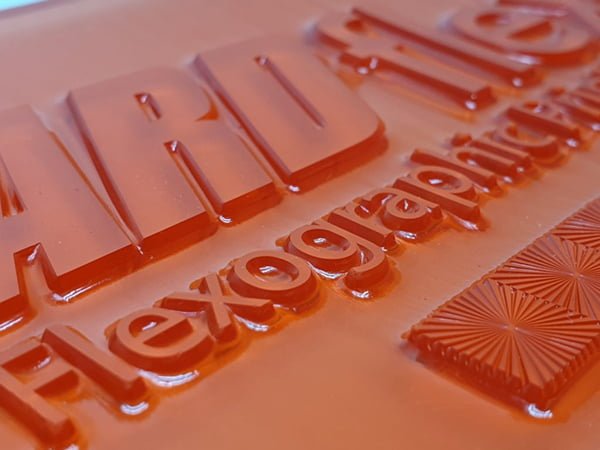

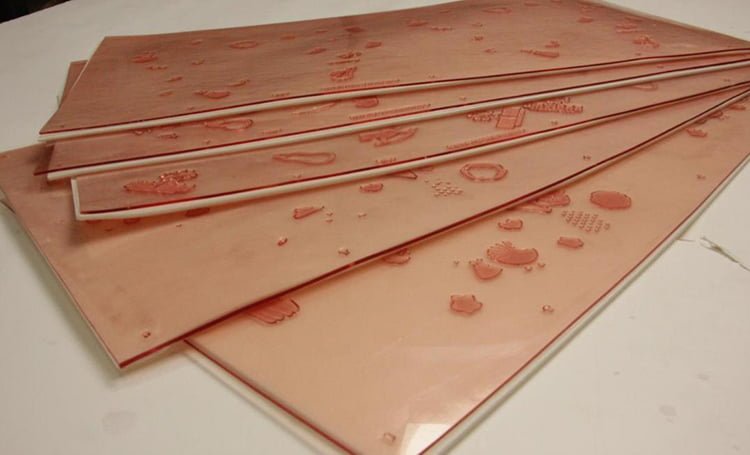

Flexo printing includes the use of a photopolymer material plate.

This flexible plate is wrapped around a central cylinder for each color, and on its surface are raised graphics.

Our Jota flexo printing machines are equipped with 4 different rollers, each plays a critical role:

- Impression cylinder

- Plate cylinder

- Fountain roller

- Anilox roller

The fountain roller sends the ink to the anilox roller.

Anilox roller transfers the ink to the plate cylinder’s raised sections.

Afterwhich, the ink is applied to the substrate when substrates pass between the plate cylinder and the impression cylinder.

The impression cylinder “impresses” or applies pressure to the plate cylinder on to the substrate.

It is on this substrate, that your creative designs are printed.

What is flexography printing used for?

As the name suggests, flexography printing is considered the most flexible printing.

To meet various customers’ different printing needs, unique combinations of sleeves, printing plates, ITR engraving, and printing machine types can play an important role.

With the right ink, flexographic printing can print clearly on almost all substrates.

The flexo printing equipment has comprehensive processing capabilities, it can be combined with offset printing, gravure printing, screen printing, etc.

And many post-printing processes can be integrated into 1 flexo printing machine, such as:

- Varnishing

- Hot stamping

- Online coding

- Embossing

- Die-cutting

We outline some of the most common market applications below for flexographic printing.

- Flexible packaging

- Trademark label

- Folding cartons and paper cups

- Corrugated paper

- Consumer goods industry

- Medical and pharmaceutical industries

- School, home, and office supplies

What substrates could be used for flexo printing?

You could use plenty of substrates for flexo printing.

This means that the flexo printing machines could easily meet your specific printing needs.

These substrates include:

- Papers (uncoated and coated)

- Liner board

- Carbon board

- Aluminum foil

- Bio-oriented polypropylene (BOPP)

- Low-density polypropylene (LDPE)

- Fabrics

- Laminates composed of different types of substrates

Flexo printing technology

Flexo printing is in fact evolved from letterpress printing, but it has now become an independent type.

It has the advantages of letterpress printing, lithography printing, and gravure printing.

The printing effect is clear, soft, with high gloss, and has its own distinctive characteristics.

The flexo printing’s most distinctive feature is its excellent environmental protection performance.

This is beyond other printing’s reach.

Flexo printing is called “green printing”, which is especially suitable for packaging product printing.

Flexo printing is widely used in food and pharmaceutical packaging.

- (1) Flexo printing widely uses low-toxic alcohol-soluble inks and non-toxic water-based inks, completely discarding toxic aniline inks, and has a good environmental performance.

- (2) Flexo printing can better solve the solvent residues in flexible packaging composite films.

Flexo label printing

Self-adhesive label flexographic printing’s market share in China has been increasing year by year, and the most obvious growth is reflected in the fields of VP printing (variable data printing) and label printing for cosmetics, beer, and beverages.

These fields’ characteristics are long-run, high-volume printing.

Flexographic printing is most ideal for printing self-adhesive labels, which can gradually replace letterpress printing.

Compared with letterpress, flexographic printing quality has two major advantages:

- 1. The ink dots are full and the deformation is small (UV ink).

This is due to the flexo printing’s low pressure and a uniform ink supply;

In letterpress printing, if the pressure is not adjusted well or the printing plate layout is not flat, the dots will appear white centers and white circles, which will cause dot distortion.

- 2. The ink color is stable, and speed changes will not cause color differences in the printing process.

Because the flexo printing machine uses metered ink delivery, it is not affected by speed.

Any rotary letterpress printing machine operator has such experience, as the machine’s speed changes, and the ink amount in the fountain changes.

Even if the pressure is not adjusted, the substrate’s ink color will change, resulting in color difference.

The above 2 points are the biggest advantages of label flexographic printing, operators who have used both rotary letterpress printing machines and flexographic printing machines all have such feeling.

China’s self-adhesive label flexographic printing is mainly affected by the plate making’s high cost, long cycle time, low profit for short runs, and large investment in machine accessories.

Flexo film

The flexographic plate is a soft letterpress plate.

When printing, the printing plate is in direct contact with the plastic film and the printing pressure is light.

Therefore, flexographic printing requires higher flatness of the flexographic plate.

Therefore, when installing the plate, pay special attention to the cleanliness and flatness of the printing plate and the plate cylinder, and use double-sided adhesive tape to stick the flexographic plate.

For plastic film flexographic printing, because the film surface is not absorbent, the anilox roller’s line screen should be lower, generally choose 120-160 lines/cm.

The tension control during flexographic printing has a great influence on the plastic film’s overprinting, graphics, and text transferring.

If the printing tension is too large, although it is beneficial to accurate color registration.

After printing, the film’s shrinkage rate is large, which will cause dot deformation.

On the contrary, if the printing tension is small, it is not helpful to accurate color registration.

Image registration is not easy to control, the dots are also easy to deform, and finally, affect printing quality.

Flexo textile printing

There are generally several printing methods for fabric or textile printing:

- 1. Pigment printing

- 2. Silk printing

- 3. Discharge printing

- 4. Burn out printing

- 5. Flat screen printing machine

- 6. Puff printing

- 7. Flocking printing

- 8. Tropical printing

Flexo textile printing is still rare in the market.

Pannier company has been developing flexo textile printing machines for printing fabrics, and they’ve made great progress in developing such machines.

If you want to learn more about or purchase flexo textile printing machines for printing fabrics, you can contact the Pannier company.

UV flexo printing

In recent years, some major changes have taken place in the packaging and printing industry.

Affected by regional promotional activities, short-run jobs have become many packaging and printing businesses’ main jobs, and its scope involves:

- Food packaging

- Pharmaceutical packaging

- Beauty and health care product packaging

- Folding carton production

The fiercer competition on the merchandise shelf shows that sellers and printers must try to innovate, and they should release extremely eye-catching labels and outer packaging.

The product’s outer packaging is the last mouthpiece of itself.

Suppliers respond to market demand by developing new substrates, UV inks, and coating materials.

Therefore, there are many new methods currently used to produce labels.

It is also common to combine several printing processes so that printing quality equal to lithographic and gravure printing can be obtained.

The printing equipment supplier responded in a timely manner and work hard to innovate, in order to always be at the forefront of a constantly changing industry.

The equipment that has been launched can handle a variety of substrates, and the job conversion speed is fast.

It can be printed with more than one printing process in one circle.

When several printing processes are used for printing, products printed with UV inks and coating materials have greatly improved color stability and physical properties.

At present, flexographic printing presses on the market can integrate a variety of process, including:

- Flexo or UV flexo

- Gravure

- Silkscreen

- Rotary letterpress

- Lithography

- Rotary hot stamping

Recently, new changes have taken place due to the need for market share.

Research shows that narrow web printing presses are getting wider, while wide web printing presses are getting narrower.

This has created interesting new cross-overlapping markets, such as using UV flexo printing technology to produce folding cartons on linked printing presses, which is undoubtedly a challenge for traditional sheetfed offset printing press manufacturers.

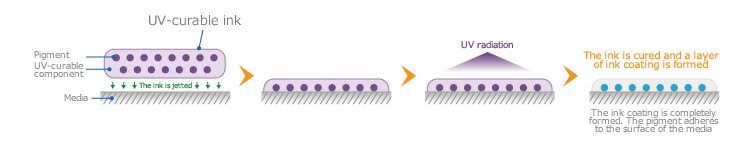

- UV curing system

Existing printing materials and future printing materials need to be treated with unique heat treatment methods.

With the increasing use of heat-sensitive film labels in the packaging and printing industry, the demand for efficient and rapid curing of UV inks and coatings (without damaging the substrate and causing alignment errors) has also increased.

Manufacturers launch UV curing equipment that can be used flexibly with existing or new printing presses.

At present, the narrow, medium, and wide web printers can be equipped with UV curing devices alone, or with hot air and UV drying curing devices at the same time.

- Variable factors of the substrate and ink UV curing

Variable factors that affect the substrate and ink UV curing include:

Curing depth, surface temperature, and the substrate’s different physical properties.

The requirements for each curing are also different due to the image accuracy, the detail level, and the substrate type.

The cured ink must provide different ink film weight, color density, adhesion, and bending flexibility for different products.

Printing on the board box with UV ink requires the use of western unique ink.

This type of ink is easy to transfer, and it also takes into account the substrate’s different characteristics and performance.

- The interaction of UV ink and UV lamp

Many interactions occur between UV inks and UV lamps, which not only affect the final product’s characteristics but also determine the UV curing equipment’s operation efficiency.

We know that light is composed of photons, and photons are the basic unit of light energy, usually traveling in a straight line at light speed.

Each photon has a certain wavelength, and its energy is related to the wavelength.

When a photon passes through an object, it is reflected, refracted, or absorbed.

After the photon is absorbed, the photon first transforms into another energy form, usually heat energy, and the chemical change it causes is called photochemical change.

- The chemical properties of UV photoinitiator (active ingredient)

UV ink is a photochemical compound, usually composed of 4 materials:

Monomers, oligomers, pigments (and other additives), and photoinitiators.

The only optically active ingredient is a photoinitiator, which can react with ultraviolet light’s certain wavelength.

When the ultraviolet light’s photons collide with the photoinitiator’s molecules, the curing reaction is initiated.

Photon absorption efficiency

- The chemical properties of UV photoinitiator (active ingredient)

When using UV inks, you should remember the following two important things:

If there is no collision with the photoinitiator, the photons are wasted;

The photoinitiator of certain wavelengths’ photons do not activate, such photons are also ineffective.

All components of UV ink have a light-shielding effect, especially shielding UV light.

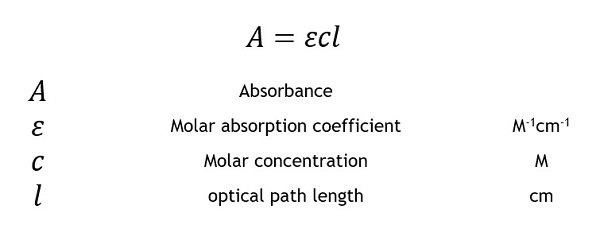

When light passes through an absorptive substance, its intensity decreases according to the Beer-Lambert law.

This law describes how light intensity becomes smaller due to the ink film’s thickness and absorption characteristics.

Two other basic conclusions can be drawn from this:

The molecules of the photoinitiator are evenly dispersed in the UV ink;

The photons directed to the UV ink substrate’s surface are unevenly distributed on the ink layer.

- The energy intensity (UV irradiance)

Irradiance is sometimes called the UV lamp’s energy intensity, which refers to the printing surface’s irradiance power per unit area at any time during the curing process.

The irradiance’s unit is watts or milliwatts/cm2.

Its value is the UV lamp’s maximum irradiance value, which can usually be obtained at the UV lamp’s focal point on the substrate surface.

The greater the irradiance, the greater the irradiation power of any layer in the ink film.

- UV radiation dose

The term dose here refers to the amount of exposure time, or refers to the energy released on the surface within a certain period of time, the dose’s unit is Joule or millijoule/cm2.

Is the curing effect produced by a dose of 1W/cm2 in 1s the same?

The answer is no.

Because the dose does not indicate the irradiation depth and does not fully describe the released UV amount.

We used UV ink to print on polycarbonate substrates with 154 lines/cm of screen lines and then cured them under different UV lamp irradiation conditions.

After comparing the curing effect, it is found that the UV irradiance, not the radiation dose, plays a key role in the curing effect.

Keep UV lamp irradiation conditions unchanged, let the printed graphics and text pass once or twice under the UV lamp with different peak irradiance power, and then compare the irradiance and irradiation dose’s impact to the UV ink curing depth.

Letting the printed graphics and text pass twice under a lower power UV lamp did increase the curing depth, but it did not double as expected.

In fact, if the printed graphics and text pass under the UV lamp for the 3rd time, the curing increase will be further reduced.

Increasing the irradiation time cannot compensate for the UV lamp’s insufficient irradiation intensity.

- Choice of spectrum

The wavelength of ultraviolet light is 200-450 nanometers.

The limit of a short wavelength is 200 nanometers because if the wavelength is shorter, it will not be able to spread in the air.

At about 450 nanometers, it is the starting point of the visible light spectrum.

When using silkscreen UV ink, the two bands have an effect at the same time.

Short waves have an effect on the ink surface, while long waves have a deeper effect inside the ink.

Losing the short wave, the ink surface will become sticky.

If the long wave is lost, the ink adhesion will decrease.

- UV curing lamp

The UV curing lamp uses mercury as the main light source.

Some metal halides are often added to the lamp to obtain different ultraviolet spectra UV curing lamps.

Because all UV lamps contain mercury, which produces a variety of wavelengths, including shortwaves, the ink’s surface can be cured to a certain extent through shortwave energy.

The added metal halide can increase the output of specific ultraviolet (longer wavelength), then the UV ink’s drying and curing degree, adhesion can be enhanced.

Some commonly used UV lamps include:

- H-type lamp, for transparent bright ink;

- D-type lamp, for some color screen printing inks;

- V-shaped lamps, for ink which is difficult to penetrate/white ink.

- Past defects

In the past, when metal halide-added UV lamps were used, the disadvantage was that the power regulator needed to be adjusted frequently.

Now with stepless variable transformers power supply, UV lamps can be started without adjustment.

- Reduce heat and surface temperature, control IR

When the substrate cannot withstand too much heat or the UV coating may be damaged by overheating, temperature becomes a problem.

For example, in color screen printing, in order to minimize the point increase when using UV ink, the temperature must be controlled lower.

During the use of infrared UV lamps, due to the temperature increase, infrared (IR) energy (not produced by mercury or metal halides) will be generated and emitted by the quartz tube.

The air-cooled device in the drying and curing system can be used to reduce the surface temperature, and the substrate can pass through the curing chamber at a faster speed to reduce the surface temperature.

- Customer and market demand

Consumer goods distributors will continue to demand greater options for printing images in order to maintain their current market share.

A variety of printers, an increasing variety of printing consumables, and the continuous advancement of UV curing technology can meet the above-mentioned needs of distributors.

Plate mounting flexo printing

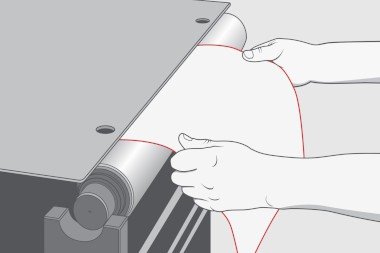

Printing plate installation is a very important step in the flexographic printing process.

If the printing plate is installed improperly, the cost will increase.

Follow the steps below to install the printing plate, you can avoid the downtime caused by the wrong printing plate installation.

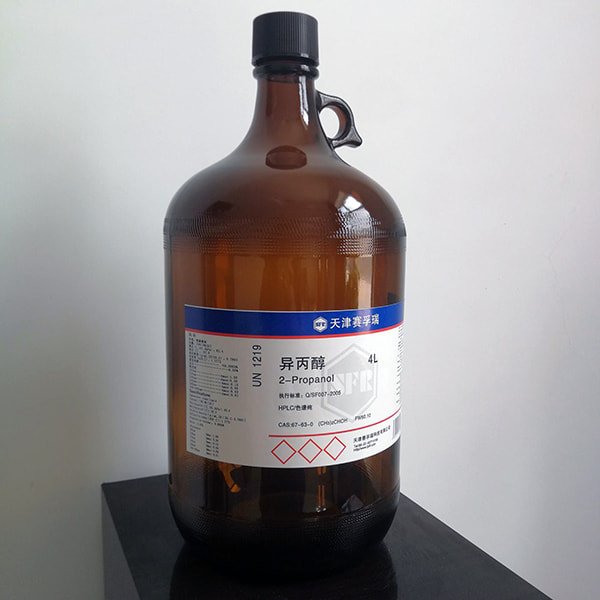

- Clean the plate and plate cylinder correctly

In order to better clean the printing plate and the plate cylinder, we recommend that you use a clean cloth dipped in normal temperature isopropyl alcohol to wipe.

Or you can use a disposable paper towel dipped in isopropyl alcohol to wipe.

Before entering the 2nd step, let the printing plate and plate cylinder dry for a few minutes.

- Stick the double-sided tape on the plate roller

After the printing plate and plate roller are dry, please stick the double-sided tape on the plate roller.

- Tip: Cut off the excess tape after marking.

- Install the printing plate

Place the printing plate on the plate roller.

And with the help of the plate mounting auxiliary equipment, verify whether the crosshairs on the plate mounting auxiliary equipment are aligned and whether the printing plate is horizontally and vertically straight.

After confirming the alignment, remove the liner from the tape.

- Use a brayer to roll on the printing plate.

When rolling, the hand must apply firm and even pressure to the brayer, ensures that the printing plate is firmly bonded to the plate roller by the tape.

Digital flexo printing

With the high-performance digital flexo printing machines’ continuous improvement and development, the quality of folding carton flexo printing reaches the level of offset printing, while the cost is much lower.

The application of digital technology has promoted flexographic printing technology’s development, especially in the field of folding cartons.

The flexographic printing of roll carton is developing very fast, and it is more and more accepted and adopted by more people, and it is gradually replacing the single-sheet carton production method.

The new breakthroughs and new developments of flexographic printing sleeve technology have far-reaching significance in controlling the dots and dot gain rate, which greatly improves the quality of flexographic printed products.

The introduction of a new digital shaftless flexo production line has also promoted the flexographic printing quality to a certain extent.

At present, the flexographic printed folding cartons have basically reached the quality level of most offset printing ones.

Recently, someone conducted a market survey of 250 folding carton flexographic printing companies in North America.

The survey results showed that:

- The processing method of single-sheet material will show a downward trend, the market share decreased from 63% in 1990 to 51% in 2000;

- In-line processing of web materials (including flexographic printing methods and offset printing methods) will have great growth, and the market share will expand from 35% in 1990 to 47% in 2000.

- The gravure printing market continues to show a downward trend, accounting for 15% of the market in 1990, and by 2000, it will drop to 10%.

The market share of flexographic web printing doubled in the decade from 1990 to 2000 (from 8% in 1990 to 16% in 2000).

Therefore, even if roll offset printing’s market share has doubled in these 10 years, from 10% to 20%, the offset printing folding cartons’ total market share is still declining, from 75% in 1990 to 70% in 2000.

The European folding carton market’s investigation and analysis show that the folding carton industry is currently at a very critical turning point.

It is changing from the previous wide-format, single-sheet gravure printing and simple flexographic printing to a narrow-format shaftless roll flexographic printing.

Such a method has the advantages of higher automation, greater adaptability, and higher production capacity.

Due to the flexible and diverse digital shaftless rotary die-cutting system’s introduction and application, multiple processes can be completed at one time, because such a system integrates cutting, embossing, and other processes.

It greatly reduces production costs.

The early roll folding carton production line used flatbed die cutting equipment.

Flatbed die-cutting equipment needs a long adjustment time, and its stability is poor, its production speed is very low.

Thus it is difficult to compete with the new single-sheet production line in terms of cost and efficiency.

Today’s flexo die-cutting system is very different, and the performance has been greatly improved.

It uses rotary die-cutting equipment with a maximum width of 55 inches (1400 mm) and a maximum speed of 1200 feet per minute (400 meters per minute).

At the same time, it also has a “quick change” device, which can quickly change the printed materials to be cut.

Some systems also have a gearless lifting platform device, which can process complex semi-finished folding cartons.

Another advantage of in-line rotary die-cutting is that there are more and wider choices of molds, especially shaftless molds and curved molds, and the price is very low.

Compared with the traditional short-run single-sheet carton production market, it is quite competitive.

Consolidation within the carton industry continues, and industry competition will become more intense.

With the new roll folding carton production line put into use, it will definitely impact the existing folding carton processing plants and folding carton printing plants.

Some folding carton processing plants, especially folding carton printing plants, will gradually be eliminated.

- Analysis conclusion

The technological revolution of digital prepress technology and a digital printing machine will surely bring new vitality to the web flexographic printing process.

The new technologies’ application will continuously improve production levels and improve operational performance.

Therefore, digital prepress technology and digital printing presses have a high return on investment.

However, for various types of roll flexographic production lines, it is very important for a printing plant to carefully analyze the balance between its budget and production efficiency, and to choose the most cost-effective equipment.

The new all-digital multi-function flexographic production line for online reel processing is mostly equipped with a rotary cutting device, embossing device, or winding device, which is fast and quick to change materials.

Therefore, the labor intensity is reduced, the rejection rate is reduced, the production efficiency is improved, and the investment value is more.

Flexo printing VS gravure printing

As an environmentally friendly printing, flexographic printing is gradually replacing gravure printing.

Especially under the background of increasing environmental protection policies, many printing companies that originally used gravure printing turn to transform.

According to relevant data, gravure printing’s market share is gradually declining, and the corresponding flexographic printing market share is increasing.

What causes this situation to happen?

From the perspective of a printing company, what are the advantages of flexographic printing?

Although flexographic printing and gravure printing are basically the same in technology, including unwinding, printing, drying, winding, etc., there are big differences in details between the two.

In the past, gravure printing combined with solvent-based inks for printing, the effect was significantly better than flexographic printing.

Now with the great development of environmentally friendly ink technologies, such as water-based inks and UV inks, the advantages of flexographic printing have begun to emerge.

Features of flexographic printing

- 1. Lower cost

The cost of plate making is much lower than that of gravure, especially when printing in small batches, the gap is huge.

- 2. Less ink consumption

Flexo printing uses a flexographic plate, which transfers ink through anilox rollers, and consumes more than 20% less ink than gravure.

- 3. Fast printing speed and higher efficiency

Flexo printing machine with high-quality water-based ink can easily reach 400m/min printing speed;

In common gravure printing, the printing speed can often only reach 150m/min.

- 4. More environmentally friendly

In flexographic printing, water-based inks, UV inks, and other environmentally friendly inks are generally used, which are more environmentally friendly than solvent-based inks used in gravure printing, and there is almost no VOCS emission.

Features of gravure printing

- 1. High cost of plate making

In the early days, gravure plates were made by chemical etching, but the effect was not good.

Now, laser plate-making can be used, so the precision is higher, and the printing plate is made of metal such as copper, it is more durable than the flexible resin plate.

However, the cost of plate making is also higher, and the initial investment is greater.

- 2. Better accuracy and consistency of printed products

Metal printing plates are more suitable for mass printing, and have better printing consistency, and are less affected by thermal expansion and contraction.

- 3. Large ink consumption and high production cost

In terms of ink transfer, gravure printing consumes more ink, which invisibly increases production costs.

Through the above comparison, you should have a general understanding of flexographic printing and gravure printing.

Flexo printing VS digital printing

The difference between flexo printing and digital printing is mainly reflected in the following aspects.

- Basis

Digital printing is the process of transferring images or text to various substrates by inkjet or laser printing technology.

Flexographic printing is a process of batch printing, printing images or text through flexographic printing equipment.

- Cost

The initial investment in digital printing is relatively low, but in the latter, the consumables and maintenance costs may be higher.

For large projects with a print volume of more than 50,000, it is not suitable for digital printing.

Flexographic printing’s initial investment is higher, but if the projects’ printing volume is more than 50,000, the printing cost of labels or other substrates can be greatly reduced by flexo printing.

- Turnaround time

When printing several thousand or fewer labels, the turnaround time for digital printing is relatively short.

But when printing 50,000 labels, flexographic printing has more advantages than digital printing.

- Ink options

There are basically only three colors of toner for digital printing or inkjet printers.

Optional ink types for flexographic printing have a wider range.

- Substrate

Flexographic printing can print a wide range of substrates.

Digital printing can print very few types of substrates.

- Continuous printing capacity

Digital printing’s continuous printing ability for a long time is insufficient;

And flexographic printing has the ability to print continuously for a long time.

Flexo printing vs letterpress

Flexo printing is actually a kind of letterpress printing, which evolved from letterpress printing.

In order to facilitate understanding and distinction, people refer to the printing method using liquid ink and flexible printing plate as flexographic printing;

The printing method using paste ink and a hard printing plate is called letterpress printing.

- Principles of Printing and Inking

The letterpress printing device uses one or several ink rollers, these ink rollers transfer a uniform and thin ink layer to the printing plate’s surface in an integral form and then print.

The flexographic ink is transferred from the metal anilox roller to the printing plate through contact.

The specifications of the anilox roller are fixed, so the ink transfer volume is also fixed.

The ink is stored in the cell before transfer.

Because the mesh wall in the cell is very thin, during the transfer process, the ink in each cell is in contact with the printing plate at the same time

And the ink in each cell is quickly leveled and integrated to form an ink layer on the printing plate, and finally printing.

The two are really different in the principle of inking.

The letterpress is a soft rubber stick in contact with the hard printing plate, and the ink amount depends on the ink layer thickness;

The flexographic plate is the contact between a hard metal anilox roller and a soft printing plate, which depends on changing the anilox roller’s specifications to change the ink amount.

- Inking system

In order to transfer the paste ink evenly to the printing plate, there is a complicated inking system on the letterpress printing machine, including:

Ink fountain, ink fountain roller, ink transfer roller, distributing roller, inking roller, etc.

This system is called the long ink path system.

Only through the long ink path system, the paste ink can form a uniform ink layer.

Flexographic printing uses liquid ink and does not require a complicated inking system.

It only needs an ink fountain roller to transfer the ink to the anilox roller or directly contact the anilox roller with the ink (gravure inking method).

The ink on the anilox roller’s surface is finally removed by the doctor blade, and the ink is stored in the cells.

This ink transfer method is called a short ink path system.

The short ink path system is simple in structure, easy to adjust, and low in material consumption, which is the flexographic printing’s biggest feature.

- Printing ink

According to the principle of printing and inking, the letterpress printing ink is transferred to the printing plate in the form of an overall film, which requires a certain strength and connection between the inks.

Otherwise, the ink cannot form an ink film, and it cannot be transferred normally.

Therefore, letterpress ink is a paste ink with a certain viscosity.

The flexographic printing ink transfer relies on the rapid flow and leveling of the ink from the cells.

The flexographic printing ink is required to have low viscosity and fast transfer speed.

Therefore, the flexographic printing ink is a liquid ink with low viscosity and good fluidity.

- Adjustment of ink volume

There are usually two ways to adjust the amount of ink in letterpress printing.

1. Adjustment of the overall ink volume

(1) Adjust and change the ink fountain roller’s rotation angle or speed, the ink transfer amount will change.

(2) Adjust the ink transfer roller’s swing frequency to increase or decrease the contact time with the fountain roller, thereby changing the ink transfer volume.

2. Adjustment of local ink volume

On the letterpress printing machine’s ink fountain, there are screws that locally adjust the ink volume, and a set of screws are evenly arranged along the axial direction.

By adjusting the screw, change the gap between the ink fountain steel plate and the ink fountain roller.

By changing the size of the gap, the amount of ink corresponding to the screw can be adjusted locally.

The anilox roller on the flexographic printing machine is actually an ink metering roller, and its technical parameters are fixed, which means that the ink transfer amount is fixed.

Only by changing the anilox roller with different parameters can the ink delivery volume be changed.

Therefore, the change of the flexographic printing ink amount is achieved by replacing the anilox roller.

Restricted by printing principles, flexographic printing can only perform overall ink adjustment, not partial ink adjustment.

- Printing plate

Although both letterpress and flexographic printing plates use photosensitive resin plates, the two plates’ thickness, hardness, and formulation are different, so the film production and the plate making methods are also different.

1. The printing plate thickness and hardness

The photosensitive resin plate used for letterpress printing generally has a thickness of less than 1mm, and the commonly used specifications are 0.8mm and 0.95mm.

The thickness of the flexographic resin plate is generally between 1 to 5 mm, and different substrates are selected for different thickness plates.

In terms of the printing plate hardness, the finished letterpress printing plate’s hardness is generally around 90 degrees Shore, while the finished flexographic printing plate’s hardness is between 30-70 degrees.

This is what people usually say, letterpress printing plates are hard, and flexographic printing plates are soft.

But there is no absolute dividing line between the two, soft printing plates are also used in letterpress printing plates, which are suitable for full point printing;

Hard printing plates are also used in flexographic printing plates, suitable for dot text printing.

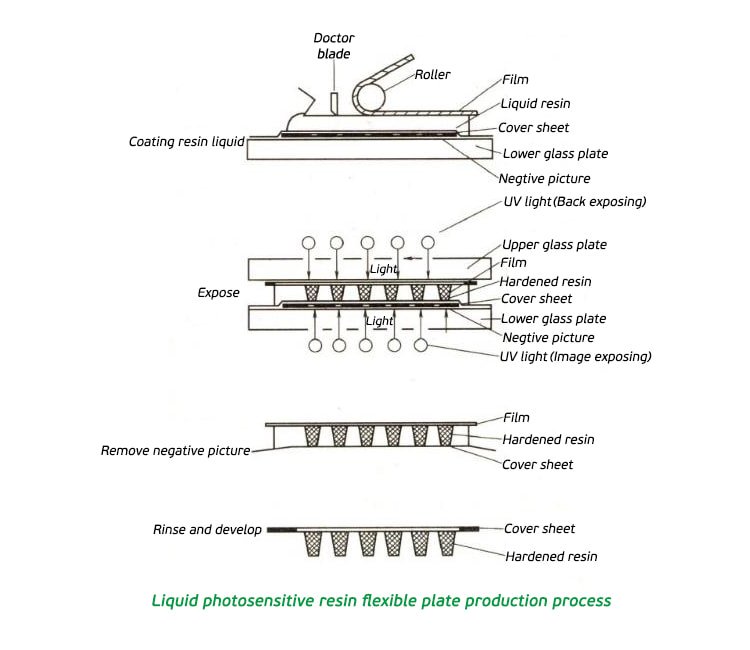

2. Production of printing plates

There are two differences in the production of letterpress and flexographic printing plates.

One is the difference in plate making steps.

The plate making steps of letterpress printing plate are:

- Main exposure

- Developing

- Drying

- Post exposure

In order to control the flexographic plate’s height and hardness, the first step is back exposure, followed by main exposure and developing.

In order to remove the viscosity on the printing plate’s surface and better transfer the ink, a debonding process was added in the plate making step.

And then dry the plate after debonding, finally, the printing plate surface was post-exposed and hardened.

Compared with letterpress plate making, flexographic plate making adds back exposure and debonding processes.

The second is the difference in developing liquid.

The thickness, resin composition, and formula of letterpress printing plates and flexographic printing plates are different, so the types of plate developing solutions are also different.

Letterpress developing liquid uses distilled water as the cleaning medium, while the flexographic washing medium is a specially formulated solvent (water-washed flexographic materials are not yet popular).

The medium used in the two printing plates are different, and the drying time is also different.

Usually, the letterpress printing plates drying time is several minutes to 10 minutes;

The flexographic printing plates drying time is from 1 hour to 10 hours.

- Printing pattern

1. Imprinting effect

The letterpress and the flexographic plate’s printing principle is the same.

There is an imprinting effect on the printing pattern, that is, the ink is squeezed out on the edge of the pattern, and there are traces caused by reflow.

This phenomenon appears on the outlets (especially when the pressure is high) as the center is white or there is a white circle;

Slight ghosting can be seen at the edges of text or lines.

The letterpress and flexographic printing plates’ thickness and hardness are different, and the printing plate’s deformation during printing is also different, which ultimately leads to different imprinting effects.

The letterpress printing pressure is high, the imprinting effect is obvious, and the contrast is large;

The flexographic printing pressure is small, the imprinting effect is slight, and there is a transition (the difference between letterpress printing and flexographic printing needs long-term practical observation and comparison to realize).

2. Printing color

The flexographic ink’s pigment solid content is significantly less than that of letterpress ink, so the color density of letterpress ink printed matter is significantly greater than that of flexographic printed matter.

Because the color of letterpress printing is bright, there is no obvious difference in printing quality from the flexographic printing plate.

This is the main reason why letterpress printing is prosperous in Europe and Asia.

3. Ghost phenomenon

Also known as the offset shadow, it is a common phenomenon in letterpress full point printing.

The main reason is that the applied ink amount is less than the supplied ink amount, which occurs in large-area full point printing.

Since the anilox roller in flexographic printing continuously supplies ink to the printing plate without interruption, ghost images will not appear in flexographic printing.

4. Full point printing

The ink layer of letterpress printing is even;

In flexographic printing, if you use water-based ink, you will find traces of water lines on the pattern.

What is the difference between litho and flexo printing?

The difference between flexographic printing and lithographic printing is mainly reflected in the following aspects.

- 1. Cost

Lithographic printing can be equipped with stamping, embossing, and other functions, the cost of these optional functions is relatively high.

And lithographic printing needs to go through indirect pre-printing first, which will also increase costs.

For high-volume printing needs, both printing methods are cost-effective.

For flexographic printing, the flexographic printing plate can be reused many times before replacement.

- 2. Substrate

Lithographic printing is usually only used for printing substrates with smooth and flat surfaces.

Flexographic printing can be used to print substrates with porous and non-porous surfaces, with a wide range of substrate compatibility.

- 3. Ink

Lithographic printing usually uses four-color oil-based inks for printing, and each color requires a dedicated printing unit.

Flexo printing can use a variety of inks for printing, including water-based inks, solvent-based inks, and UV inks.

- 4. Printing quality

The lines and text printed by flexographic printing are very beautiful.

The choice between flexographic printing or offset printing still depends on the substrate type, investment budget, and specific production requirements.

What is the difference between offset and flexo printing?

Both offset printing and flexo printing can be used to print labels, but their printing principles are different.

Although narrow web printers prefer flexo printing, offset printing has its own advantages and disadvantages.

The offset printing ink transfer system is more complicated, consisting of multiple ink rollers, and the ink path is long.

The two printing methods use different inks.

Dave Pan Coast, Sales Manager of LabelOneConnect, USA, said:

“The ink used in flexo printing has a viscosity similar to milk. The flexo printing plate is made of resin, and the ink on the printing plate is directly transferred to the substrate.

“The ink used in offset printing is pasty and heavy, the coloring power is large. The ink is first transferred to the printing plate, then transferred to the blanket, and finally transferred to the substrate. The ink transfer system is not simple.”

JesHilfling, general manager of Etipol in Denmark, pointed out:

“Offset printing must use UV drying, while flexo printing can be dried with hot air, infrared, or UV.”

The offset printing and flexo printing’s ink flow are also different.

Hilfling explained:

“The ink flow for flexo printing is controlled by the mesh volume of the anilox roller, while for offset printing, the ink volume is adjusted by the ink fountain key.”

Hilfling also pointed out the similarities between flexo and web offset printing.

He said: “The preparation time for the two printing methods is the same, and the printing speed is very fast.”

Flexography Printing Process

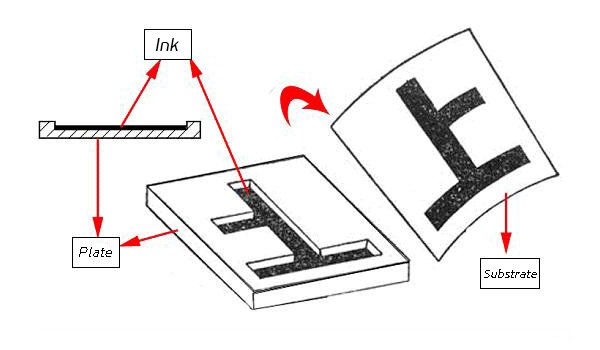

Flexo printing basics/principles

Flexographic printing is a printing method that uses a flexographic plate to transfer ink through an anilox roller.

The layout structure of the printing plate is the same as the letterpress printing plate.

The graphic part is raised (that is, the graphic part is higher than the non-graphic part), and they are all directly printed.

After the plate cylinder is installed, a certain thickness of the ink is evenly coated on the graphic part of the printing plate by the anilox roller.

And then, under the action of the printing pressure (applied by the impression cylinder), the ink layer of the graphic part is transferred to the substrate, clear graphics and text are printed on the substrate surface.

Therefore, flexographic printing is a direct printing method.

This printing method needs to use rubber or photosensitive resin printing plates and quick-drying liquid inks.

Flexographic printing process steps

Flexographic printing mainly includes two major steps: plate making and printing.

The plate making process is:

- Original

- Film

- Back exposure

- Main exposure

- Developing

- Drying

- Post-processing

- Post-exposure

- Mounting plate for printing on the machine

The printing process is as follows:

- Substrates

- Printing (including reverse printing)

- Varnishing or laminating, etc.

- Die-cutting

- Cut off

- Inspection

- Warehousing

Production Precautions

- 1. According to the original and customer requirements, select the appropriate color number, color sequence, format and corresponding plate roller (number of teeth, number of screen lines, etc.).

At present, many flexographic printing originals are transferred from offset printing.

There is a big difference between the two printing processes.

It is impossible to copy the originals from offset printing (especially the color separation process).

Process the original according to the flexographic printing process’s characteristics, combined with the performance of the flexographic printing machine, and coordinate with the customer.

- 2. The adjustment of printing pressure, printing speed and tension of each part should be appropriate.

Because the flexographic plate is composed of a layer of hard polyester plate base and highly elastic photosensitive material, its most obvious feature is its elasticity.

In the printing process, a slight printing pressure is applied.

A slight change in printing pressure will also cause changes in color and gradation, leading to the image dots expansion on the printed matter.

Moreover, the greater the printing pressure, the more serious the dot expansion.

The printing speed should be determined according to the specific production situation.

When the machine starts, start at a low speed, adjust the position of each color’s plate cylinder, and then gradually increase the machine speed after registering, and should be compatible with the ink drying performance.

At the same time, it should be noted that the machine speed should not be too fast to prevent ink splashing, causing unnecessary waste and even affecting production.

The tension adjustment and control are very important.

If the tension is not proper, it will cause inaccurate overprinting, feeding deviation, and uneven winding.

- 3. During the printing process, check the ink viscosity, PH value and drying performance at any time.

For the flexographic printing ink control, mainly these 3 aspects.

In the production process, due to water and solvent volatilization, the ink performance becomes unstable, the viscosity increases, and the pH value decreases, which affects the printability.

Therefore, during the printing process, at regular intervals, an appropriate amount of PH stabilizer or corresponding solvent (to be combined with specific printing speed and ink drying conditions) should be added to adjust the ink PH and viscosity.

At the same time, since the flexographic printing plate is short-station printing, the stroke between color and color is relatively short.

If the solvent in the ink is not completely dried, it will cause poor color stacking or adhesion.

Flexographic printing process PDF

Please input filetype:pdf flexographic printing process in the google search box, piles of related pdf file download pages are listed on your PC or laptop monitor, just figure out which one is the best, then download it for your own usage.

Flexo printing design

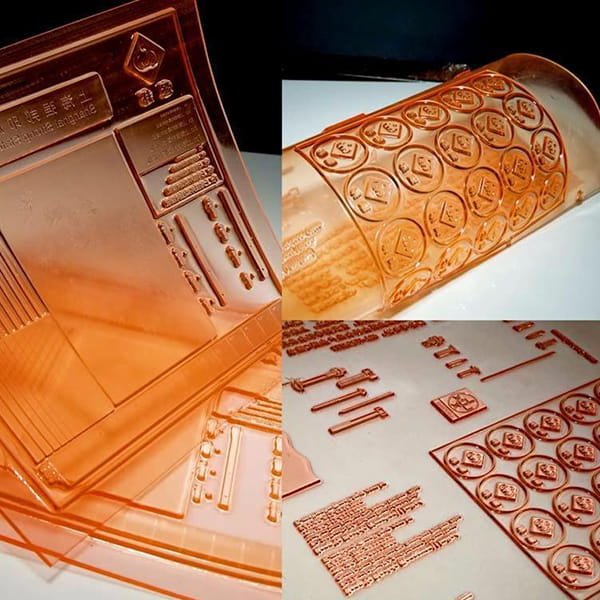

Regarding flexo printing design, it is mainly referred to as a flexographic printing plate design.

As flexo printing is developing faster and faster, more and more flexo printing plate design companies or suppliers appear.

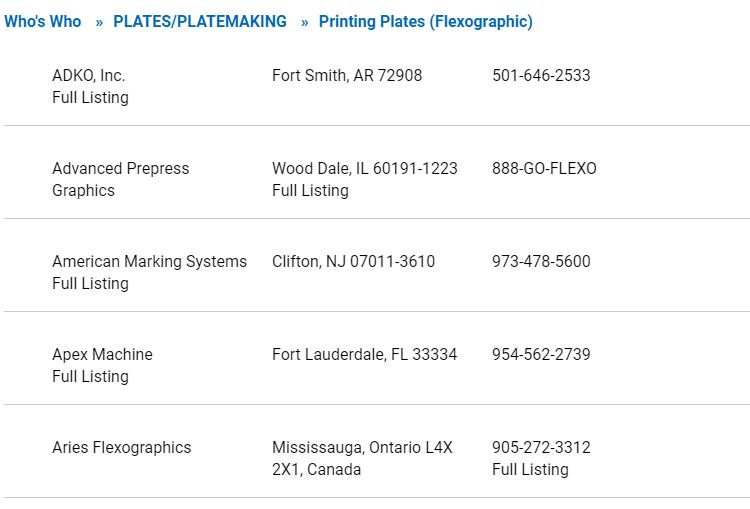

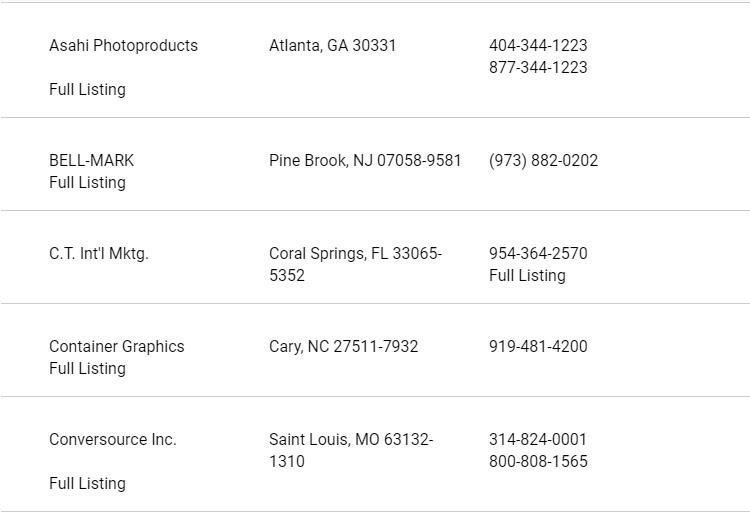

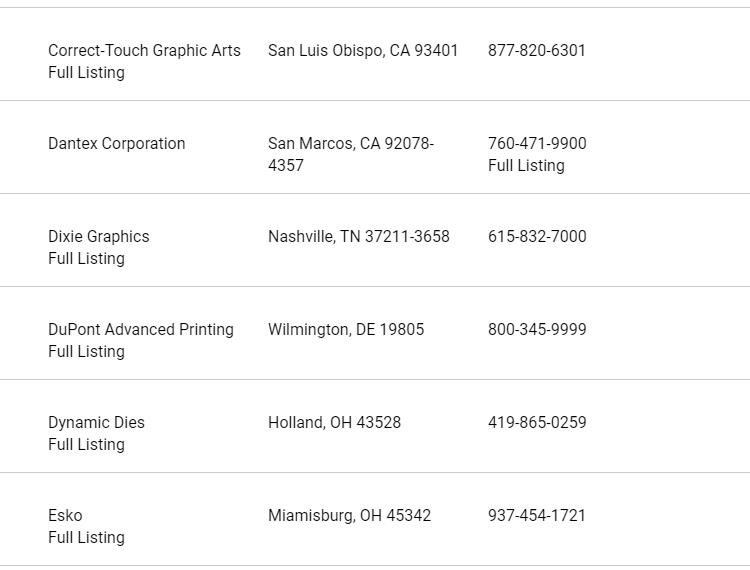

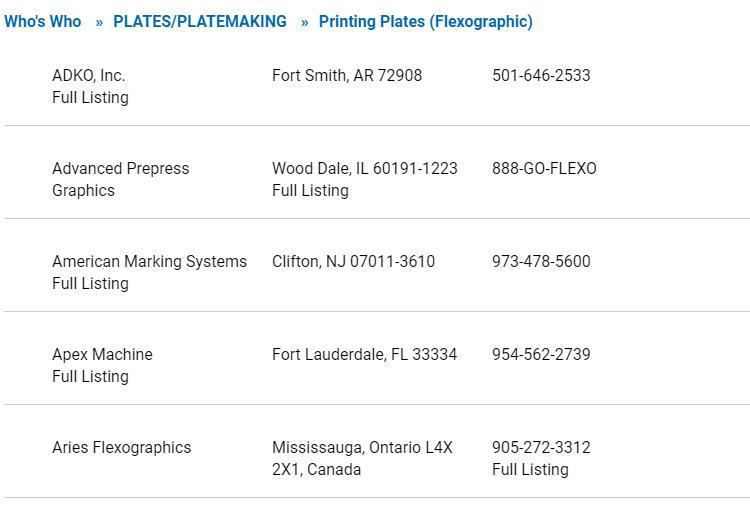

According to flexoglobal website’s information, famous flexo printing plate and sleeve manufacturers are listed out, as shown in the following photos:

Anilox flexo process

The flexographic printing machine uses a typical short ink path system with a relatively simple structure, mainly composed of four parts:

- Ink tank

- Fountain roller

- Doctor blade

- Anilox roller

Among them, the anilox roller is the core component, which is responsible for evenly transferring a certain amount of ink to the printing plate.

Ink cell shape

Several common inking cell shapes include:

- Quadrangular pyramid

- Quadrangular pyramid

- Hexagonal pyramid

- Trapezoidal cross-section oblique line

- Additional channel ink cell

The ink-receiving cell opening and depth have a considerable influence on the ink transfer performance.

The larger the opening and the shallower the depth, the better the ink transfer;

On the contrary, the ink transmission is relatively poor.

Among the several ink-receiving cell shapes mentioned above, the hexagonal pyramid-shaped ink-receiving cell’s opening is relatively large, so its ink-receiving and ink-releasing performance are better.

Therefore, in engraving anilox rolls, inking cells of this shape are often used.

Screen lines

The anilox roller’s screen lines refer to ink cells number per unit length on the anilox roller’s surface.

It is also one of the important parameters of the anilox roller.

It also has a very important influence on the ink transfer performance.

Generally speaking, the higher the screen lines of the anilox roller, the smaller the ink transfer volume.

In addition, the screen lines of the anilox roller also determine its own scope of application.

Generally speaking, when printing large-area full point color blocks or images, consider using a low-line anilox roller.

For example, when printing on a full point area, 360 lines/inch anilox roller can be used;

On the contrary, when printing fine images or small texts and lines, a relatively high screen lines anilox roller should be used.

Such an anilox roller can prevent the small dots in the highlighted area from being immersed in the ink cell, which may cause serious tone value expansion, or very thin lines become thicker.

However, the anilox roller’s screen lines should not be too high.

If the anilox roller’s screen lines is too high, it will cause certain difficulties to the anilox roll processing technology;

Moreover, since high screen lines anilox roller’s thickness becomes thinner, the strength will be reduced and the damage is likely to occur.

In other words, if the anilox roller’s screen lines is too high, its service life will be shortened accordingly.

Classification

Anilox rollers are classified according to the materials coated or sprayed on their surface, and there are mainly two types of chrome anilox rollers and ceramic anilox rollers.

Processing of Chrome Plated Anilox Roller

The processing of chrome-plated anilox rollers usually includes 3 processes:

- Roll body pre-processing

- Anilox processing

- Post-processing

The laser engraved ceramic anilox roller is a plasma method to melt the metal oxide (Al2O3 or Cr2O3), and spray it on the metal smooth roller’s surface to form a high-hardness, strong and dense ceramic film with the metal roller.

After grinding, polishing, and then use a laser beam to engrave ink cells on the ceramic surface.

Regarding anilox rollers’ inventory in the printing factory, with the business development and growth, for ease of use, the most suitable anilox rollers can be selected according to the requirements of different prints.

A list of the inventory anilox rollers should be made.

If this list is only classified by LPI, only the anilox roller’s screen lines can be known, but the cell volume (BCM) cannot be known.

The necessary parameters cannot be provided when selecting.

For example, the same 800LPI anilox roller, some may be 1.0BCM, while others maybe 1.8 or larger BCM, the ink transfer amount during printing is very different.

Therefore, in addition to the anilox roller LPI, the anilox roller BCM must be recorded separately in the inventory list.

In addition, due to the long period of anilox roller usage and maintenance quality, the anilox roller surface or wall is worn or blocked by ink residues, and the printing effect is also very different.

Therefore, it should also be noted when preparing the anilox rollers inventory.

When ordering anilox rollers from the manufacturer, the user should clearly specify the processing parameters, including:

- Lines per inch

- Cell volume

- Engraving angle and unengraved sideband width (if mentioned)

In addition, since there are always certain differences in processing, it is best to order processing in batches even if the same LPI and BCM are processed for anilox rollers.

Anilox roller for flexo printing

Anilox roller is a special ink transfer roller for flexographic printing machines.

There are countless cavities of the same size, shape, and depth on the surface.

These cavities are also called cells (or ink cells).

The concave cells can store ink, as shown in the picture.

The anilox roller’s function is to quantitatively and uniformly transfer the required ink to the graphic part on the printing plate.

It can also prevent ink splashing when printing at high speed.

Composition

- 1. Roller body-cast iron

- 2. Base material-stainless steel alloy (copper electroplating)

- 3. Surface coating-chrome, ceramic

- 4. Cells

- 5. Mesh wall

1) Roll body (also called roll core)

Its processing dimensional accuracy and geometric accuracy have a direct impact on the ink transfer accuracy.

Therefore, it is generally required to undergo fine processing to ensure good mechanical processing accuracy, so that the dimensional accuracy, surface roughness, geometric accuracy, etc. all meet the ink transfer roller’s quality requirements.

2) Base material

The surface engraved on the anilox roll is called the base layer, and the base layer is generally added on the roll body.

The base layer material is very critical to the anilox roll life and performance.

The selection should be comprehensively considered in terms of strength, corrosion resistance and processing performance.

(1) Strength-mainly refers to the ability to resist local rush out.

If the base material is too soft, large deformation will occur under the impact force, which will cause the chrome layer or ceramic coating on the anilox roll surface to peel off.

(2) Corrosion resistance-refers to the resistance to ink solvents.

If the base material is too hard, the processed cells may be uneven and cracks will appear in the mesh wall.

According to the above requirements, some anilox roll manufacturers choose stainless steel alloy as the base material and spray it on the surface of the roll core.

In order to ensure good processing performance, the most commonly used base material is electroplated copper.

3) Surface coating

The metal anilox roll surface is plated with chromium after processing, and the ceramic anilox roll is sprayed with a layer of ceramic on the anilox roll surface before engraving, which is called surface coating.

Its main function is to improve the anilox roll abrasion resistance and prevent the solvent from corroding the base layer’s copper coating.

The thickness of the general surface coating is:

The chrome layer is 0.0127~0.01778mm, and the spray ceramic layer thickness is 0.0254~0.03048mm.

4) Cells

The meshes of modern engraving anilox rollers mostly adopt regular hexagonal openings.

The use of such mesh openings for ink supply is beneficial to increase ink supply amount and better avoid the production of moire on the printed matter.

If a fully symmetrical circular opening is adopted, the mesh wall between the cells is enlarged, and the number of cells per unit area is reduced, which not only reduces the ink supply, but also reduces the ink transfer uniformity.

The characteristics of the quadrilateral opening are somewhere in between.

The ratio of the opening width to the cell depth is also closely related to the ink transfer amount.

If the cell opening is narrow and deep, the ink at the bottom of the cell cannot be transferred, thus reducing the ink transfer in the cell to the printing plate rate, it may even be permanently blocked due to the inability to clean the bottom.

It is generally believed that the ratio of cell opening width to depth is about 28%.

5) Mesh wall

It refers to the partition wall between the cells, and the mesh wall size is related to the shape of the cell.

For example, a regular hexagonal mesh opening is smaller than the mesh wall area per unit area of a fully symmetrical circular opening.

In order to increase ink supply and improve ink transfer performance, the mesh wall area per unit area should be minimized.

What is the difference between 4-color and 6-color printing processes?

Jota Machinery offers a range of different color options for your requirements.

4 color printing is the most popular option of the three.

It uses the four primary ink colors: cyan, magenta, yellow and black ink, also known as CMYK.

On the other hand, 6-color printing takes the 4 color CMYK and adds orange and green colors.

With this option, you will be able to create more colorful and vivid graphics and images.

Flexography Printing Machine

Paper flexo printing machine

The paper flexo printing machine, as the name suggests, is a printing machine.

The printing plate used by this printing machine is a flexographic plate, which is suitable for printing all kinds of paper, such as:

- Coated paper

- Newsprint

- Light coated paper

- Double offset paper

- Writing paper

- Dictionary paper

- Book paper

- Doolin paper

- Drawing paper

- Art paper

- Carbon paper

- Fax paper

- Copy paper

- Photo paper

- Thermal paper

- Inkjet paper

- Film paper

- Sulfuric acid paper

- Toilet paper

- Facial tissues

- Napkins

At present, only a small part of China’s domestic flexo printing machines are used for printing self-adhesive materials, and most of the products printed by flexo printing machines are thin paper printing materials.

Almost all users who have printed thin paper will report a series of problems.

These problems can be summarized in the following words, namely:

- “Wrinkle”

- “Shrink”

- “Curl”

- “Static”

- “Paper Break”

Below, we will discuss in detail the causes and solutions of these failures.

1. “Wrinkle”

When the flexo printing machine handles the thin paper, the first problem that occurs is “wrinkle”.

The paper produces “wrinkles” on the machine along the paper feeding direction.

The wider the machine (that is, the wider the paper) and the thinner the paper, the easier it is to wrinkle.

- Reason (1): Excessive tension.

The general situation is that if the machine’s certain local tension is too large, wrinkles will be generated in this area and affect the following parts.

For example, sometimes the unwinding tension is set too high, and wrinkles are generated in the unwinding part, and the more the wrinkles go to the back, the more serious the wrinkles, and even the paper breaks.

Some users originally ordered a thick paper type flexo printing machine, once used to print thin paper, it is easy to wrinkle.

At this time, wrinkles generally occur in the middle and back of the flexo printing machine.

- Solution

This problem can be solved by reducing the tension setting value of each part.

But the most fundamental solution is to purchase a set of rollers suitable for printing thin paper.

- Reason (2): The EPC device deflection angle is too large.

The tension of the paper at the EPC device is tight on one side and loose on the other side, so it leads to wrinkles.

If it is the unwinding part, “bark” wrinkles will appear on the NIP roller.

Of course, this phenomenon occurs on the paper’s looser side.

- Solution

Feed the paper slowly for a short run, adjust the appropriate horizontal position of the paper, and stabilize it, then stop, and then adjust the EPC device sensor to make it match the paper that needs to be monitored.

The edge position is aligned, and the web guiding system is switched to the “automatic” state.

In this way, the EPC device deflection angle during the “automatic” working process can be minimized, and the possibility of wrinkles can be minimized.

At this time, make a clear mark on the paper roll lateral position, and make sure to align the position when changing to the next circle.

- Reason (3): There are foreign objects (such as large dry ink blocks) or dents on the NIP roller surface, the parallelism of individual rollers is out of tolerance, etc.

- Solution

In addition to adjusting the tension and checking the machine, if necessary, two layers of electrical tape can be wrapped around the NIP roller surface.

The position is about 15mm away from the paper’s two edges, so as to prevent the paper from moving inwardly.

NIP roller with a spiral line can also be used to spread the thin paper outwards.

However, when the thin paper stiffness is too small and the tension is relatively large, it will wrinkle due to the spiral, so a specific analysis of specific issues is required.

In addition, when printing with thin paper, after the original paper roll is removed from the package, the paper near the outer package’s surface will absorb moisture in the air and cause wrinkles.

When the wrinkled outer layer of paper enters the machine, it will definitely cause problems.

Of course, this situation is only temporary.

As long as this part of the paper is passed at a lower speed, or simply cut off and reconnected, the production can be started normally.

As for how to avoid the above-mentioned problems, we suggest that during transportation and storage, the paper roll packaging should be strictly ensured.

When it is about to be printed on the machine, the packaging should be removed to minimize the time for the paper roll to absorb moisture in the air.

2. “Shrink”

- Cause

In order to improve production efficiency, the current flexographic printing presses pay much attention to improving the drying capacity, it generally uses natural air, hot air (divided into high, medium, and low) and infrared (infinitely adjustable and non-adjustable), etc.

1 kind of drying method or their combination, some machines are also equipped with a two-stage UV curing system.

In this way, in proofing or production, people will find a phenomenon, that is, a set of plates made of the same set of film, there will be deviations in the horizontal size.

The error is small, less than 1 mm;

When the error is large, there is 2-3mm.

In practice, we have found that if there is no problem with the film or printing plate, the horizontal size deviation is caused by the two opposite processes of “wetting” and drying.

As everyone knows, about 50% of the water-based ink is water.

For thin paper, if water-based ink is printed on a large area, the “wetting” on the paper surface will expand and become wider.

The larger the printing area and the lower the anilox roller screen lines, the wider the phenomenon will be.

When drying after printing, the paper will become narrower due to “shrink”.

The greater the heating amount and the more water volatilizes, the narrower the width of the paper will be.

The heating and drying systems of most flexo printing machines (including UV curing systems) have a starting point at a minimum speed, such as 15m/min.

For safety’s sake, when the speed is lower than this value, the infrared and ultraviolet drying devices will not be turned on, and will only be turned on when this value is reached or higher.

It is conceivable that if our boot speed is only slightly higher than this speed value, the paper heating will be very large, and the shrinkage will be obvious.

The farther the unit is, the greater the horizontal overprint error.

- Solution

In the printing production process, the printing speed should be increased as much as possible, and unnecessary hot air or infrared drying should be minimized in the production, so as to avoid horizontal overprinting errors.

We used to print tipping paper on a 20-inch wide flexo printing machine and increased the speed to more than 80m/min to ensure that there would be no horizontal overprinting errors.

Of course, there is one exception.

When we use cloth pattern vacuum aluminized paper to print beer labels, there is a big deviation in horizontal overprinting.

After careful inspection and testing, the factors that caused the width change due to the moisture loss during drying were eliminated.

Finally, it was found that even if the machine was empty, the paper width would change.

The reason may be the change of paper tension on the machine.

3. “Curl”

The “curling” mentioned here refers to the warping of the paper along the paper feeding direction.

At this time, if you look along the paper feeding direction, you will see that both sides of the paper or finished product are upturned.

As modern packaging machinery is running faster and faster, the requirements for product quality are inevitably higher and higher.

Once the printed product is warped, it will bring some trouble to the packaging assembly line.

- Cause

To explain in a simple sentence, the warpage is caused by the difference in tension (stress) between the front and back sides of the thin paper, and most of it is caused by the humidity change on the paper surface.

No matter how thin the paper is, it has a certain thickness.

If one side (or both sides) of the paper is damp (humidified) and the tension between the front and back sides is inconsistent, and the paper stiffness in the fiber direction is generally better than the horizontal direction.

Then under the combined action of the two, the paper will inevitably warp.

Thick paper is less likely to warp because of its better overall stiffness.

- Solution

For the warpage of paper and products, we can analyze it in 4 stages:

- 1. Observe the paper condition in the unwinding part, that is, without printing, just pull the paper out of the paper roll for a period of time and compare it.

Ordinary single copper paper is slightly warped at this time.

This is because the moisture content of the base paper roll is generally only about 5%.

In a workshop with a relative humidity of about 50%, the moisture content can be increased to about 7%.

In the process of moisture absorption, due to the coating on the paper front side, some moisture will be prevented from entering the paper from the front side;

The backside is relatively more damp, causing the paper to curl slightly.

Of course, the front coating will also limit the paper fibers’ deformation.

- 2. Start printing water-based ink and water-based varnish, but do not apply UV varnish.

The boot speed is appropriately higher, and the semi-finished product after printing is cut into small single sheets and placed on the table to observe the results.

There are two cases here:

If the full point plate is printed on a large area and the startup is slow, warping will probably occur;

On the contrary, if the printing area is smaller and the booting speed is faster, there will be less warpage.

This is because after the paper front is printed with water-based ink or water-based varnish, the surface of the paper is damp and deformed at the beginning, and there is a short-term “buckling” phenomenon, which is the opposite of warping.

However, after drying, especially when the amount of heating is large, the damp part will “shrink” on the paper surface after losing water, that is, the paper surface has tension and causes warping.