JT-SLT-1400C Thermal Paper MG Paper Roll Slitting Rewinding Machine

- China’s 1st 1400mm width thermal roll slitting machine

- Small roll output +55% compared to 900mm width machine

- Shaftless hydraulic jumbo roll loading

- Photoelectric sensor or photocell for web guiding

- 90-degree vertical lay-on roller

- Banana roller prevents the overlapping problem

- Specification

- Operation Manual

- Video

| PARAMETERS | |

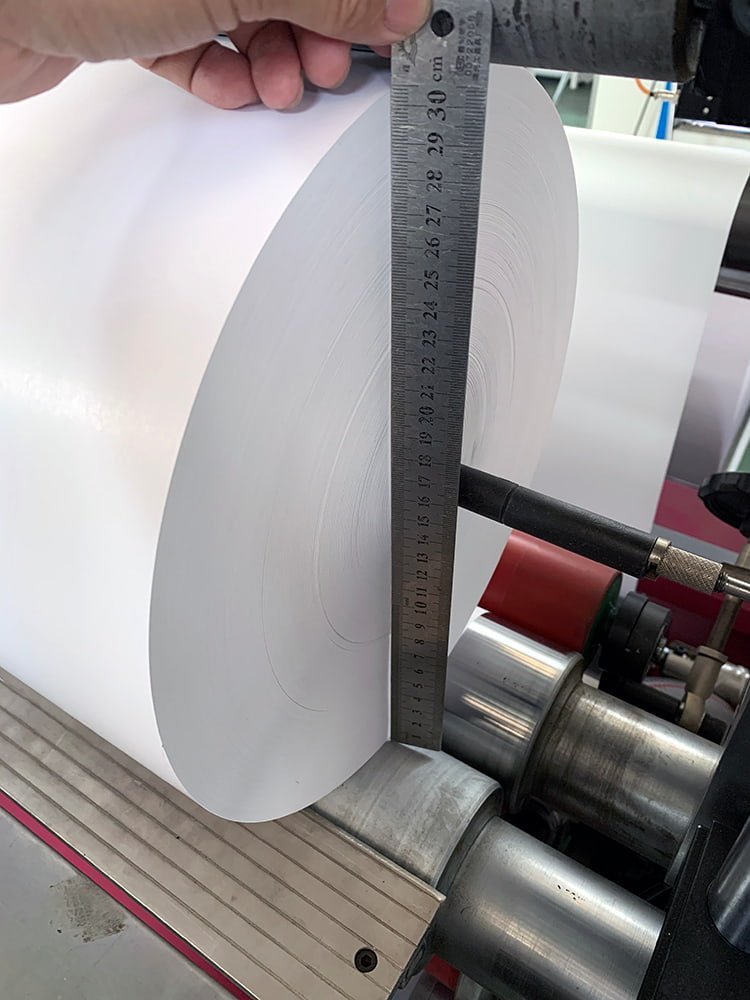

| Max. Rewinding Diameter | 300mm |

| Min. Slitting Width | 30mm |

| Max. Unwinding Diameter | 1200mm |

| Max. Unwinding Width | 1400mm |

| Max. Speed | 300m/min |

| Unwinding Shaft | 3″ (76mm) air expanding shaft |

| Rewinding Shaft | 0.5″, 1″ (size customizable) |

| Total Power | 5Kw |

| Voltage | 380V/50Hz |

| SPECIFICATIONS | |

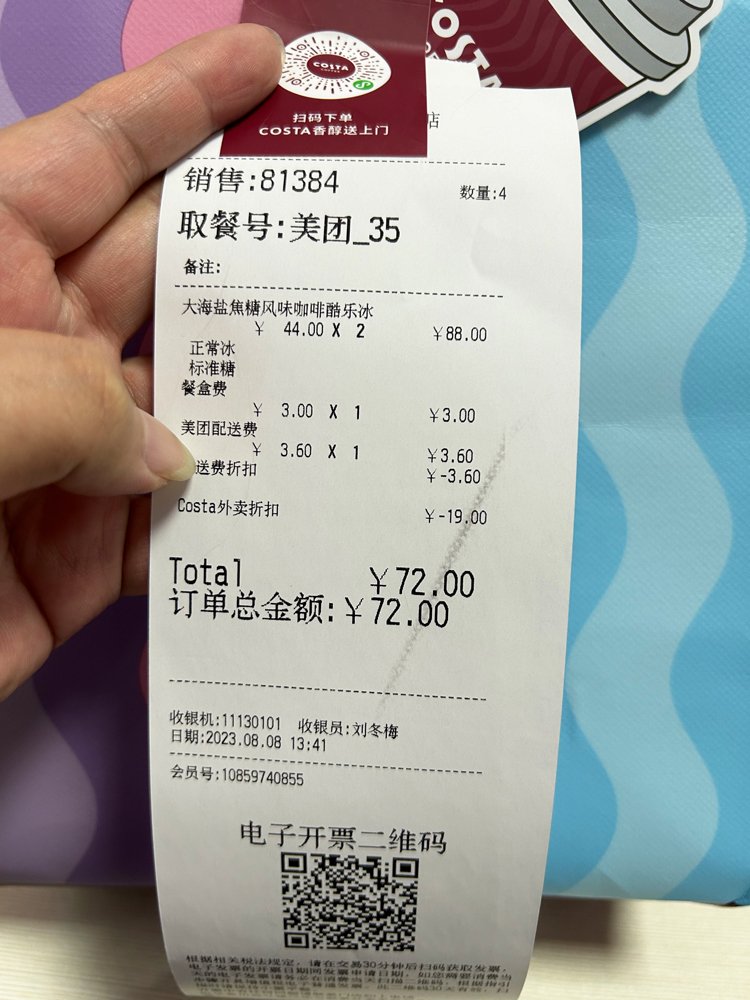

| JT-SLT-1400C thermal paper MG paper slitting rewinding machine is able to make fax roll, cash register roll, ATM roll, ECG roll, POS roll, till roll, MG kraft paper roll, etc. | |

Unwinding Section | Shaftless unwind stand, hydraulic jumbo roll loading. |

| Fully automatic tension controller. | |

| 20kg/m2 electromagnetic brake from Taiwan. | |

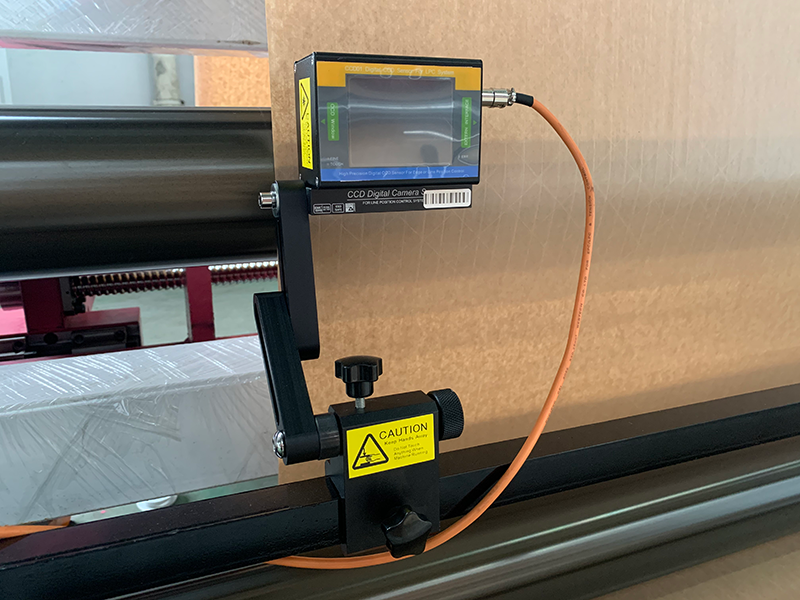

| Photoelectric sensor or photocell for web guiding. | |

| Direction adjustable balancing roller ensures roller itself always keeps in tight touch with the web. | |

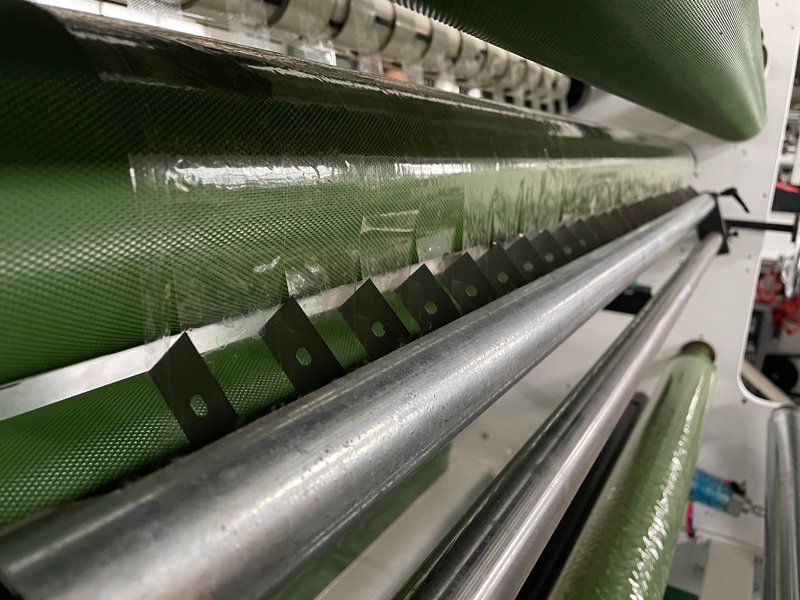

Slitting Section | The upper circular knives are fixed by screws, and the lower circular knives are fixed by the aluminum spacer, which ensures cutting precision. |

| Rotary encoder automatically metering slit length. | |

Rewinding Section | Automatic tucker tucks the tail, convenient for quickly trigger rewinding. |

| 90° vertical lay-on roller, capable of moving up and down, ensures more balanced left and right pressure, wider rewinding diameter could be realized. | |

| The overlapping problem could be avoided with banana roller. | |

Controlling Section | Siemens PLC, touch screen, and graphic user interface (HMI). |

| Yaskawa AC drive for Siemens master motor. | |

| Schneider low voltage electrical appliances. | |

Waste Removal | Edge waste blower through expulsion tube. |

Optional Parts | Safety guard. |

| 4 corners emergency switches. | |

| Transmission belt. | |

| Blower and shredder. | |

| Safety fence. | |

JT-SLT-1400C Thermal Paper MG Paper Slitting Rewinding Machine

Last Update Time:14/09/2023

Egypt client Mr. Ahmed has just bought 4 thermal paper jumbo roll slitting rewinding machines from us, one was this model JT-SLT-1400C, and he helped us shoot a promotion video for this model.

We really appreciate Mr. Ahmed’s great effort and full trust.

Of course, Jota thermal paper slitting rewinding machine’s quality is definitely worthy of Mr. Ahmed’s trust.

If Jota machine is not good, Mr. Ahmed will also turn to another thermal paper slitter rewinding machine supplier.

Some of the freshmen don’t know how to do or how to solve the issue when operating our slitting machine then we made a page for frequently troubleshooting and solution. Kindly check this page

As an extended version of JT-SLT-900C, the unwinding width of the JT-SLT-1400C thermal paper jumbo roll slitting rewinding machine is up to 1400mm.

That is to say, the finished roll output of JT-SLT-1400C is 55% higher than JT-SLT-900C.

As the positioning of JT-SLT-900C, JT-SLT-1400C thermal paper jumbo roll slitting rewinding machine is also a high-end machine.

Its slitting and winding effect is second to none.

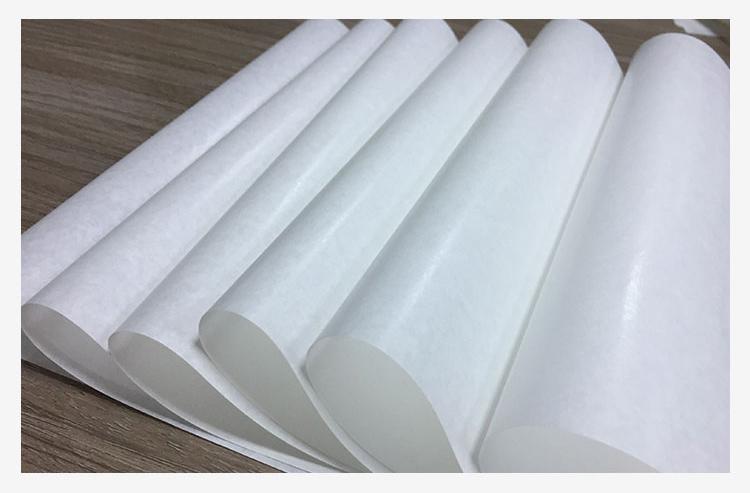

Small till rolls produced by JT-SLT-1400C are very beautiful, with very neat edges.

Such high-quality small till rolls will be very competitive in your market.

So, if you are also interested in the JT-SLT-1400C thermal paper jumbo roll slitting rewinding machine, especially care about the slitting and rewinding effect, please speed up your action to contact us for deep discussion.

In order to let you know more about JT-SLT-1400C thermal paper roll slitting machine, we Jota could briefly introduce some of its unique selling points here.

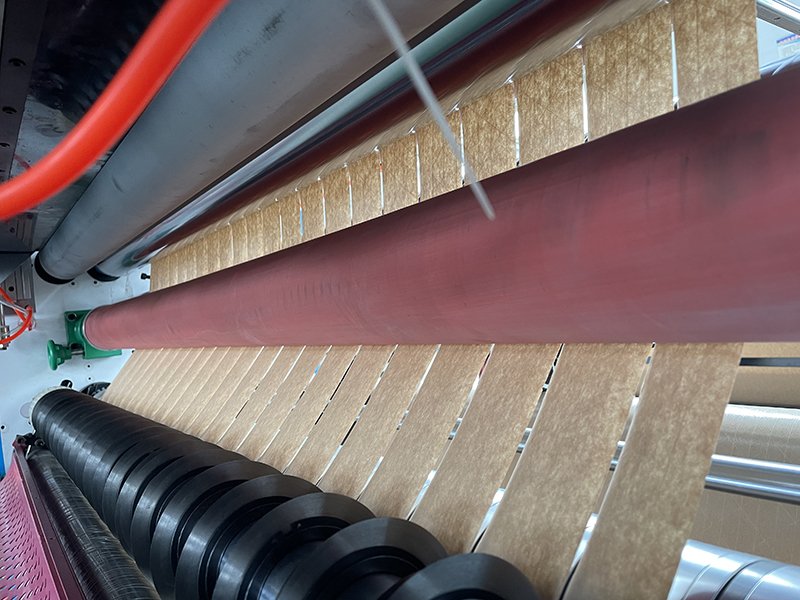

- 1. As the banana roller is installed in JT-SLT-1400C thermal paper roll slitting machine, it could spread neighborhood till roll during rewinding, thus the overlapping problem is avoidable.

Red Color Banana Roller

- 2. 90° vertical lay-on roller, it is capable of moving up and down, ensures more balanced left and right pressure, wider rewinding diameter could be realized.

300mm Diameter Finished Roll Winding

300mm Diameter Till Roll

The following video completely presents the JT-SLT-1400C thermal paper slitting machine‘s whole working process.

- 3. Photoelectric sensor web guide system, ensures JT-SLT-1400C thermal paper roll making machine’s slitting precision is much higher.

So, finished till rolls’ edge is smooth and neat, such smooth and neat edge till rolls run smoothly in the thermal paper printer, cash register, POS, ATM, assist you to attract more terminal clients.

In Jan 2021, a Taiwan client contacted our Jota boss Bruce, let’s temporarily call this Taiwanese customer TW.

TW was representing a Canadian client to purchase a direct thermal film slitting rewinding machine.

Just after 3 phone calls with Bruce, TW decided to buy our Jota’s JT-SLT-1400C ultrasound thermal paper slitting machine for his Canadian client, and TW sent us 1 ultrasound thermal paper jumbo roll for testing.

On 21 Feb 2021, we finished manufacturing TW’s direct thermal film slitter rewinder, and then tested TW’s ultrasound thermal paper jumbo roll on JT-SLT-1400C, the below video is ultrasound thermal paper slitting test video.

We sent this video to TW for confirmation together with the below photos of this JT-SLT-1400C ultrasound thermal paper slitting machine.

To understand JT-SLT-1400C ultrasound thermal paper slitter’s slitting and rewinding effect, please see the side view of the finished roll below.

The roots create the fruits.

Quality is the cornerstone of Jota Machinery, thus we Jota could gain trust from customers around the world.

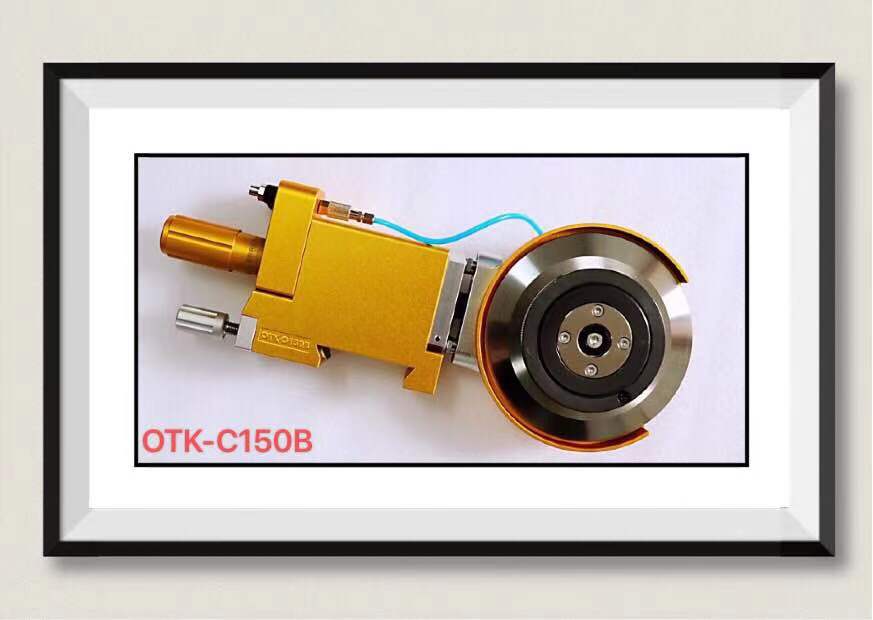

In order to reduce your labor cost and time saving, we could supply a fully automatic knife positioning system for your machine, you only need to preset the slitting width, the adjustment could be set up automatically.

Many clients suddenly contact us for small part replacement after 4-5 years of silence.

Each time we receive such mail, we could feel the client’s satisfaction overflowing from each word.

Jota Factory

Jota Professional Team

Thermal Paper MG Paper Slitting Rewinding Machine Ultimate FAQ Guide

Thermal Paper

What is thermal paper?

Thermal paper is a kind of paper coated with a color-developing material.

This kind of paper will develop color after being stimulated by a heat source, and the content of the color can be used for information recording.

With the popularity of fax machines, POS machines, ATM machines, and cash registers all over the world, the thermal paper has developed rapidly and is now widely used in shopping malls, supermarkets, banks, hospitals, airports, and many other fields.

Thermal paper weight and thickness

The thermal paper thickness is usually measured in micrometers (μm), and the thermal paper weight is usually measured in grams per square meter (g/m²).

Common thermal paper thickness/weight comparisons are as follows:

1. 55gsm-58gsm thermal paper, the corresponding thickness is 60μm/0.06mm;

2. 65gsm thermal paper, the corresponding thickness is 78-80μm/0.08mm;

3. 80gsm thermal paper, the corresponding thickness is 90μm/0.09mm.

In addition, there are some special thermal papers.

The thickness/weight comparison is as follows:

180gsm specialty thermal paper, the corresponding thickness is 190μm;

The thickness of 210gsm specialty thermal paper is 220μm.

Thermal paper usage

Compared with ordinary paper, thermal paper printing no need to use consumables such as ribbon and ink, it just needs to work with thermal printer, POS, ATM to realize printing.

Printing is very convenient and saves a lot of printing costs.

It is deeply loved by the majority of businesses.

There are many main uses of thermal paper, and it is often used as cash register paper, printing paper, label paper, etc.

The thermal paper application field is also very wide.

Supermarkets, shopping malls, movie theaters, banks, hospitals, and other places need a large amount of thermal paper.

Thermal paper specifications

The thermal printing paper’s specifications and sizes are roughly divided into 3 categories:

1. 57mm width thermal printing paper, common sizes are: 57 x 60, 57 x 50, 57 x 40, 57 x 35, 57 x 30, the size mentioned here refers to the width x diameter of the thermal paper, and the unit is mm.

2. 80mm width thermal printing paper, common sizes are 80 x 80, 80 x 100, 80 x 125, 80 x 60, 80 x 50, 80 x 40, 80 x 30, etc.

3. Thermal printing paper of the fax paper series, the common size is 216 x 30.

How much is 1 ton thermal paper?

Recently, the price of thermal paper raw materials has risen sharply.

While I am typing now, 1 ton thermal paper price is 1638 US dollars per ton.

In December 2020, the price was still US$1,495 per ton.

What equipments are needed to open a thermal roll factory?

One of the simplest thermal paper roll factories, only needs two pieces of equipment, a thermal paper slitting machine, an air compressor.

In addition to these two types of equipment, some production materials are needed, such as thermal paper jumbo rolls, paper cores/plastic cores, glue, cartons, tapes, etc.

MG Paper

Machine glazed paper

Machine glazed paper is a flat-shaped thin wrapping paper with a smooth one-sided surface.

According to the information provided by Mondi Group, a well-known machine glazed paper supplier, the weight range is 32-60g/m2.

Machine glazed paper is tough and has high bursting resistance, folding resistance, and water resistance, as well as good gloss.

This paper can be used for packaging food, daily necessities, etc., and can also be used for printing trademarks.

What is MG paper meaning?

“MG” in the word “MG paper” is the abbreviation of machine glazed, MG paper is actually a kind of kraft paper, also known as MG kraft paper.

This paper is produced by the softwood and hardwood fiber mixture.

Its main features are high gloss & strength, good runnability, satisfying printability.

This MG paper is used in the production of consumer bags, and it is also applicable in extrusion coating and food packaging lamination.

What is MG kraft paper?

MG kraft paper is also called natural food packaging paper.

The color of MG kraft paper is wood pulp color, reddish color, made of wood pulp without fluorescence, good tensile force, long fiber, and neutral PH value.

Due to the special treatment of a single side, one side of the MG kraft paper has luster, the glossy surface is smooth, and the flatness is high, and the printing effect is very good.

Common successful application cases in the market include McDonald’s and KFC’s take-out packaging bags, Rougamo (Chinese hamburger) packaging bags, and soft bags, all of which use this MG kraft paper.

Single-gloss surface, suitable for printing;

Full wood pulp, strong pulling force;

For food contact, no additives;

Good toughness and mild oil resistance.

MG bleached kraft paper

When it comes to MG bleached kraft paper, people in the industry are no strangers.

Especially in the past two years, the application of MG bleached kraft paper has been greatly expanded, and more and more users have realized the benefits of MG bleached kraft paper.

Commonly used are Japanese MG bleached kraft paper, Australia MG bleached kraft paper, and China MG bleached kraft paper.

Conventional weights are: 30 grams, 40 grams, 50 grams, 60 grams, 80 grams, 100 grams;

Main features: made of 100% pure wood pulp, food-grade, can directly contact food, uniform color, and good printing effect;

The main uses are food packaging, paper straws, cotton swabs, and other products.

From the characteristics of MG bleached kraft paper, we can find that it can do a lot in real life.

In terms of food packaging, our common biscuits, cake trays, bread, etc., internationally renowned brands such as McDonald’s, KFC, and Starbucks, also use MG bleached kraft paper.

In the past two years, paper straws made of MG bleached kraft paper are also popular.

With the rise of the environmental protection concept of “replacing plastic with paper”, it has become quite common to use paper for straws in Europe and the United States, and the characteristics of MG bleached kraft paper are in line with the requirements of paper straws.

In the future, MG bleached kraft paper will definitely shine in this field.

The selling price of MG bleached kraft paper is higher than that of many kraft papers.

Because it is made of pure wood pulp and needs to pass food-grade certification.

MG paper

In the process of producing MG paper, gluing, filling and dyeing are required.

MG paper used for food packaging must not use chemical additives that are harmful to the human body.

It requires uniform paper quality, flat paper surface, excellent front gloss, and no obvious appearance defects, and its hygienic requirements should meet the “Sanitary Standards for Food Packaging Raw Paper” (GB11680-89) regulations.

MG paper generally uses unbleached sulfite wood pulp as raw material, it is made by long fiber free form beating on Yankee single-cylinder paper machine or Fourdrinier paper machine, without bleaching.

MG paper features

In terms of physical properties, MG paper is resistant to breaking and tearing.

In terms of printing performance, MG paper has good surface strength, gloss, and smoothness.

The MG paper physical properties meet the requirements of protecting food in packaging so that the food is not damaged during transportation and handling;

Based on its printing performance, the MG paper used as food packaging can print advertisements, food information, etc.

The raw material of MG paper is wood pulp, so it is also an environmentally friendly material, which is very popular in the market.

For food manufacturers and consumers, MG paper is a perfect choice!

MG paper usage

MG paper is mainly used for drawing, designing, and paper-cutting in garment factories.

Some clothing factories do not have a computer plotter, so they need to temporarily raise the cut paper patterns on the marker paper, and then use them for cutting.

It allows you to cut out paper patterns accurately, has the advantages of non-deformation, durability, and long storage time, and is a good assistant to the cutting master.

Some industries also use MG paper for packaging food, daily necessities, etc., or printing trademarks.

MG poster paper

The MG poster paper weight ranges from 18gsm to 80gsm.

It is generally white, but can also be customized in color.

Its breaking length MD/CD is 4000/2500, Cobb (60 sec) is 30, and ISO brightness range is 68-80.

It is often used in printing, laminating, and packaging.

MG poster paper has the same outline and excellent glaze, which is very suitable for printing, laminating, packaging, and other demanding applications.

MG tissue paper

The weight of MG tissue paper is generally 15gsm-32gsm.

MG tissue paper has the same shape and excellent strength.

Its breaking length MD/CD is 4000/2500, Cobb (60 seconds) is 30, and ISO brightness range is 75-80.

Thermal Paper Slitting Rewinding Machine

Thermal paper slitting machine price

The price of a thermal paper slitting machine varies greatly due to the automation degree.

A separate semi-automatic thermal paper slitting machine, the price in the Chinese market is about 15,000 US dollars;

The price of a fully automatic thermal paper small roll production line in the Chinese market is $80,000.00-$120,000.00.

Thermal Roll Coreless Winding Machine

In 2020, Jota has made some optimizations on the thermal roll coreless winding machine, and the optimized machine runs more stable.

If you are interested in a coreless slitter, you are welcome to leave us a message and tell us your needs, and we will reply to you as soon as possible.

Please refer to the test video of the coreless rewinding machine below for reference.

Automatic thermal paper roll slitting rewinding machine

We Jota have been optimizing the automatic thermal paper roll slitting rewinding machine’s functions, and now we have integrated the online printing function for the automatic thermal paper slitting machine through our efforts.

For more details about this online printing function, please send us an inquiry on this website.

MG Paper Slitting Rewinding Machine

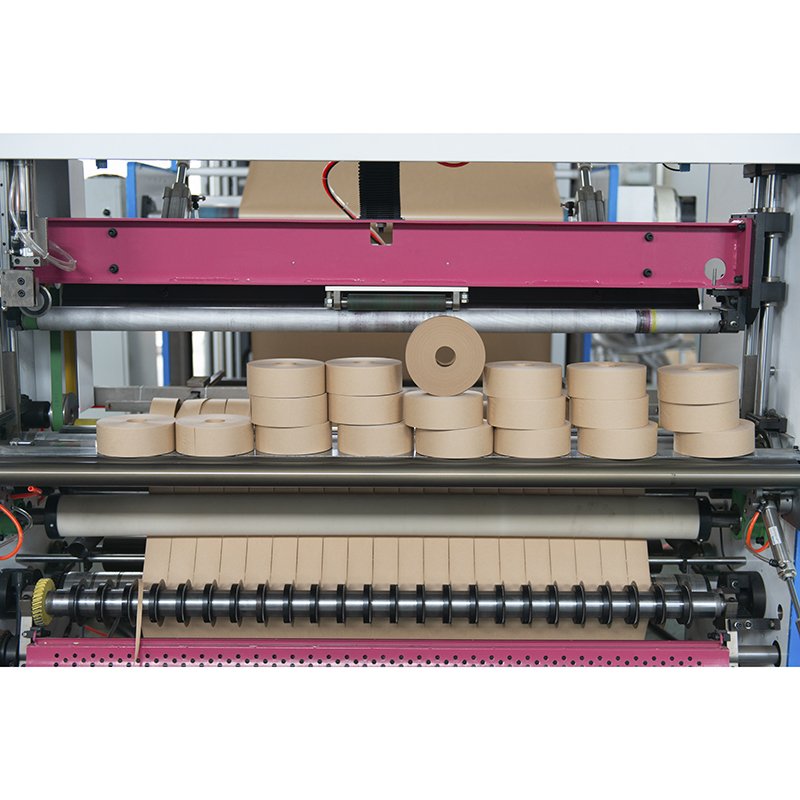

When a Taiwanese customer talked about the demand for MG paper slitting rewinding machine, he said that the rewinding shaft diameter should be 0.5 inches, and after a certain length of rewinding, the machine must cut off the paper tail before entering the next rewinding process.

These requirements exactly match the functions of JT-SLT-1400C.

Because JT-SLT-1400C was originally used for slitting and rewinding thermal paper, the diameter of the rewinding shaft is generally 0.5″ and 1″, and it cuts off the paper tail to enter the next cycle when it reaches a certain length.

Roll Slitting Machine The Ultimate FAQ Guide

- What Is Roll Slitting Machine?

- How does a roll slitting machine working?

- What is the importance of a slitting machine in your business

- What should I consider when choosing the winding type for a paper roll slitting machine

- What is the role of a winder in a roll slitting machine

- What are the most commonly used types of paper machine rewinders

- What should I consider before purchasing a slitting machine?

- How can I maintain my thermal paper roll slitting machine after purchasing

- Can one thermal paper slitting machine produce both core rolls and coreless rolls?

- Where are some of the things I should check before calling a roll slitting machine technician

What is Roll Slitting Machine?

A roll slitting machine is used in slitting (converting) film, foil, and paper materials. The roll slitting machine allows your large jumbo rolls to be converted into many small and narrower rolls. The machine is commonly referred to as a slitter or slitter rewinder.

An example of a slitter rewinder is the cash register paper roll slitting machine. It can divide the jumbo paper into small pieces of thermal paper rolls. You can use a thermal paper roll slitting machine is slitting jumbo rolls into:

– Credit card machine

– Medical Report Rolls

– Thermal Paper Rolls

– Mobile printers

– ATM – Banking Rolls

– Bank printer Rolls

– Receipt rolls

– POS – Paper Rolls for Electronic Cash Register

– Slip Rolls for Electronic Credit Card

– Ticket Machine Rolls

– Other little paper rolls

Check the explanatory video below.

A thermal roll slitting machine is made of three main parts. The parts include:

-The unwind

-Slitter

-The Rewind

Roll slitting machine will help you lower the cost of your investment. You can easily set it up and allows you to change the jumbo rolls quite fast. Roll slitting machine allows you to single cut quite fast. You can also have it operated by even a single person. This, therefore, helps your company reduce the expenses on human labour.

Apart from the paper, you can also use a roll slitting machine with other materials like:

– Double-sided adhesive tapes

– Rubber

– Self-adhesive tape

– Vinyl

– PVC among many others

How does a roll slitting machine working?

A jumbo roll slitting machine starts the operation once it’s fed with a large roll of a given material. The large roll is commonly referred to as Jumbo. The jumbo roll is fed into the slitter by the unwind. From there, the jumbo or the master roll is slit into several widths. The smaller widths of the material are then rewound by the rewind into different cores consisting of various widths.

The process carried out by the cash register paper roll slitting machine can be explained using ATM. You normally receive receipts from the ATM. These receipts were all made from a large master roll.

After being fed into the machine by the unwind, it underwent the slitting process. It is then subdivided into the desired size. The smaller sizes then went through the rewind before coming out as smaller ATM paper rolls. From there they are supplied for use to the banks and other outlets for recording transactions.

Roll slitting machines apply three slitting methods to cut the jumbo rolls. These are:

– Razorblade

– Shear cut

– Score cut

From the three methods, the type of slitting technique is fully dependent on a variety of factors such as the thickness and type of the material to be processed.

- Razor Blade

The razor blade is mainly used in abrasive roll slitting machines to slit light and non-abrasive materials. The machine utilizes a razor blade in a roll that’s grooved or on the air. The main advantage of using a razor blade slitting technique is that it is very economical. It is also very easy to set it up.

The disadvantage however is that razor blade slit does not cut rigid, heavy and abrasive materials easily. It is also possible for the razor blade slitting technique to burnish film at high speeds. If too much heat is generated, the film can also melt. This will create a bead that may hamper the possibilities of getting a perfect winding.

- Shear Cut

This kind of slitting technique uses a set of two rotary knives to get the same cutting effect produced by a pair of scissors. The shear cut slitting technique is used in slitting heavy gauge materials. Such materials include foil, thicker sheet or film and most of the laminates.

Roll slitting machine shear cutter is also known as round disc cutter. It is made of heavy-duty materials that can handle cutting heavy materials.

The benefit of the shear cut slitting technique in a roll slitting machine is the accuracy. The width of the slits and their close tolerances is always accurate.

The challenge however when it comes to the use of the shear cut slitting technique is that it requires a lot of precision. You must maintain an ideal angle at the junction of the two blades for an effective slit.

- Score Cut

This roll slitting technique is also known as “crush cut” or “Kiss cut“. It is one of the oldest forms of slitting. It was the first-ever cutting method to be used in slitter rewinder machinery. The score kiss cut roll slitting technique involves the crushing of the material on one part. It uses a dull knife pressing the material on a hard surface.

You can use Roll slitting machines with this technique to cut adhesives that are pressure sensitive. This is because it creates non-sticky and dry edges.

The main advantage of a score cut slitting technique is that it is very easy to set up. The only challenge when it comes to the use of the score cut slitting technique is the dust material. The dust may accumulate and cause malfunction.

You should get proper guidance from your roll slitting machine manufacturer. They will advise you on the right slitting technique that can be used on your machine.

What is the importance of a slitting machine in your business

Having a roll slitting machine in your company will greatly impact the operations of your business. Many benefits will come about when you use the highly efficient and durable roll slitting machine. These benefits include:

Increased Productivity

Centralized Operations

Increased Efficiency

Cost-Effectiveness

Increased Productivity: You may need to use small rolls of different materials. However, you must buy large jumbo rolls. This is the only form in which you can get the material. The roll slitting machine will offer you the ability to cut the jumbo rolls into small sizes. These are the specific sizes you need to use in your services, manufacturing or production process.

Centralized Operations: The roll slitting machine will give you a chance to centralize your production processes. Your company will no longer have to take the large rolls outside for slitting. All the work is done at your company’s premises thus centralizing all your operations.

Increased Efficiency: Using a roll slitting machine will help you reduce the use of highly inefficient human labour. Human labour may cause you a lot of errors and delays. Automatic roll slitting is very efficient and can handle large quantities of work that may otherwise take days in just a few hours.

Cost-Effectiveness: The automatic process is cost-effective due to the amount of work that is covered in a shorter time. It, therefore, creates more time for your machine operators to engage in other company activities. It also helps in ensuring that your other business processes run fast thus creating more revenue. Roll slitting machine will help you cut down any associated labour costs.

What should I consider when choosing the rewinding type for a paper roll slitting machine?

A rewinding process is very important in the smooth operation of the roll slitting machine. The choice of a rewinding type is key in determining the quality of the final smaller rolls produced. The process of rewinding a jumbo roll into smaller roles results in internal forces. The internal forces produced can easily damage your jumbo roll. This happens if you use the wrong rewinding type in your roll slitting machine and may result in great losses. You will need to consider many factors when selecting a good rewinding type. These factors include:

– The core size

– The type of the material

– The weight of the finished roll

Apart from the factors, you also need to understand the “TNT” (tension, nip, and torque) winding principles. The TNT winding principle will help you decide on the best winding method. You can see some of the common types of winding with their respective application.

- Surface Rewinding

Roll Slitting machine Surface winding is also known as friction winding. For surface winding, the web is normally driven by a single or several winding drums. The winding drums are powered by a motor. The drum is made in contact with the outside layer of your jumbo roll being rewound. This is in line with the nip principle.

It is the nip loading that will offer you great traction in between the moving drums and the winding roll. This also helps in controlling the density of the finished rolls. The difference in the driven rollers’ speed tends to exert pressure on the web material.

Another principle that will apply to the surface rewinding of the roll slitting machine is the torque principle. When the rollers and the rewinding roll get in contact you should loosen or tighten the material. You can easily control this by adjusting the torque in between the rollers.

The rewinding package driving power is not reliable on the increasing diameter. This makes the surface rewinding system less power consumption compared to the center rewinding system. The surface rewinding is very economical, easier to maintain and operate.

The surface winding is mainly used in the production of jumbo rolls with large diameters. It also works better for materials that are non-sensitive to compression or nipping. Such materials include textiles, paper, and non-woven bags among others.

- Centre Rewinding

Another rewinding type for a roll slitting machine is the Centre Rewinding that is motor-driven. Its winding force gets to the web material using the core. You can adjust the formation of the roll by altering the tension and the nip force of the rewinding system.

Roll slitting machine with Centre rewinding offers you an effective way of manufacturing material-sensitive high-quality rolls. This type of role slitting machine will wind rolls with low wound-in-tension. It handles the jumbo roll materials even more gently.

You can use a center rewinding roll slitting machine can be used for materials like:

-Composites or Nip-sensitive plastic film

-Delicate nonwovens

-Paper

-Heavy sheet

During the roll slitting winding process, the tension should be maintained at lower levels. However, the use of the centre rewinding comes with some limitations. Some of the limitations are:

-The weight of finished smaller rolls

-The power of the core or winding shaft

-The maximum diameter

The torque that is allowed from the drive motor will greatly limit the above features. It is very necessary that you get a core that can accommodate a winding shaft with a large diameter.

- Centre-surface rewinding

The Centre-surface rewinding operates by when force is applied to the rewinding process. The force is generated by the moving rewinding drum and the rewind shaft. The lay-on roll loading is applied on the rewinding roll and will control the torque and the nip.

It is programmed so as to produce in-wind tension to harden the roll in the desired profile. The surface drive is responsible for controlling the web tension. It is also used for slitting and spreading the web.

The centre-surface rewinding roll slitting machine controls the rewinding package’s density. One great advantage that comes with the use of centre-surface rewinding is its winding tension. The Centre-surface winding Roll slitting machine winding tension is controlled independently from the web tension. It is very good in winding high-slip as well as extensible webs into large diameters.

What is the role of a winder in a roll slitting machine?

A roll slitting machine rewinder is the device that will receive the jumbo reels from the machine. Once the slitter slits the material into the required width, the rewinder then rolls them. The rewinder is the one that is responsible for sizeable rolling into useful sizes. In Brief, the jumbo roll slitting machine rewinder performs the following functions:

- Unwinding the paper or material from the parent reel

- Slitting and removing the trim from both edges of the sheet

- Slitting the sheet into various and different widths

- Guiding the sheet into the windup area

- Removing the finished roll sets

The roll slitting machine rewinder will receive the large reel and feed it to the slitter. During the rewinding, the slitter then cuts the jumbo paper roll into narrow rolls. The slitter is made up of very sharp round disc knives that trim the reels. These sharp round disc knives of the rolling slitter machine are referred to as slitter knives.

The Roll slitting machine rewinders will help you transform your reel into narrower rolls. It does this by slitting the web that comes from the board machine longitudinally. The narrower rolls are mainly referred to as the shipping roll.

The shipping roll will be rewound into particular sizes depending on the intended use. The end-use will mostly be referenced as converting process. Some of the converting processes include corrugating machines, sheeters, bag machines, printing presses etc. A good jumbo or parent roll should not have any winding defects.

It should have end faces with straight edges with a clear and smooth rewinding structure. A good jumbo roll should also have its rewinding hardness as constant as possible. In other cases, the rewinding hardness should be seen to reduce to the outside from the center.

What are the most commonly used types of paper machine rewinders?

A paper roll to roll slitting machine operates in a continuous process. In this process, the rewinder is the batch operation. This continuous process will from time to time be stopped routinely so as to place a new jumbo roll on the unwinder. The routine stopping also helps in removing the completed sets from the winder.

Since the rewinder works as a batch operation, it will operate at a greater speed compared to the paper making machine. This is so as to make sure that the rewinder runs its operations with the paper machine production behind it. In comparison, the rewinder speeds will be two times much faster compared to the paper making machine.

Other than their high speeds of operation, they must also cycle their massive components with speed. This helps in reducing the downtime that may occur. The good thing about the operations of a winder machine is that all their functions are automated. This includes both the control standpoint and mechanical operations.

The drum winders are normally of three types. These include:

– Single drum winders

– Two-drum winders

– Duplex winder

- Single Drum Rewinders

For single-drum winders, the paper roll will be wound individually in its independent rewinding station.

- Two-drum Rewinders

A two-drum winder on the other hand winds the paper rolls on one axis. A cash register paper roll slitting machine with a two-drum paper winder is the most common machine. All the rolls get wound at a central point. The central points are across the width of the winder and adjacent to each other. Some of the paper that are commonly wound on a two-drum winder include:

– Board grades

– Newsprint

– Towels

– Tissues among others.

In general, terms, to handle a paper machine production, only a single two-drum winder will be required.

- Duplex Rewinder

Another most popular rewinder machine for jumbo paper roll slitting machines is the duplex slitter rewinder. A duplex rewinder is used to rewind papers that are otherwise difficult to wind. The papers that are mostly rewound using the duplex slitter rewinder are basically those papers that are coated. These are papers such as:

– Speciality high gloss papers

– Magazine stock

– Newsprint among others

These types of products are made with papers that are filled with material coatings. The paper is then processed in an extra finishing operation. This is what makes the final surface very smooth and glossy.

What should I consider before purchasing a slitting machine?

When considering buying a roll slitting machine, you must be careful to get the right machine. It doesn’t matter whether you are looking for a new slitter rewinder for a small company or a large company. It can look like a simple task when selecting what to work with.

However, making a choice on the right machine specifications may be convoluted and also difficult. This is due to a large number of roll slitting machines and equipment manufacturers available. Different manufacturers will manufacture roll slitting machines with different features.

Understanding the right roll slitting machine will not be easy. To help you get the knowledge on what is good for you, we have prepared the basic guide below:

A) What is the minimum width of the slit?

There is a general rule on when you should consider a centre-surface slitter rewinder. centre-surface slitter rewinder is very suitable if your jumbo roll material is highly sensitive. Such materials can easily get broken and as such, centre-surface is highly recommended.

Another thing to consider is rewinding shaft diameter of your roll slitting machine. If your rewinding shaft diameter is less than 25mm (1’’), use the centre-surface slitter rewinder.

With the slit widths being wider, your material will be more stable. This makes the centre-winder a much better option. It has a simple design, is very cost-effective, and has good ergonomics.

With the slit widths that are narrower, the slit material will be much more vulnerable to caliper variation effects. It will also be exposed to flutter and all this will affect the quality of your finished roll. This will mainly affect those rewinds that have larger diameters.

The centre-surface rewinder machine will provide a lot of support to the rewind from the slitting section. This minimizes the negative effects mentioned above. In the end, you will get a good quality finished roll.

B) What are the maximum weight and the finished roll diameter?

The maximum weight of the finished roll and its diameter is very important. The two will help you determine if you should have a centre-surface wind slitter or a center-rewind slitter.

If your finished roll diameters are below 800mm (32”), then your best choice should be a center-rewinder. For a 1000mm (40”) diameter roll, there are manufacturers who choose to offer both. This will depend on what your application for the roll slitting machine is.

When the rewind has a 40” diameter, you should consider having a centre-surface slitter. A lot of manufacturers will have either 40” (1000mm) or 32” (800mm) in all the duplex centre-wind slitters. This is brought about by the combination of several factors. These include:

-The tension control

-Total weight of the final rolls on the shafts

-The ergonomics

C) What is slitting type is best for your material?

C) What is slitting type is best for your material?

To find the best slitting type for your roll slitting machine, you must consider the material you will slit. There are 3 slitting types that are most common.

These types of slitting include:

– Shear: The female and male rotary knives

– Razor: The razor blade cutting that cuts “in-groove” or “in-air”

– Crush/score: A rotary blade is pressed on an anvil roller well hardened

Each of these types of slitting has its benefits. You should be able to know which roll slitting machine’s type of slitting is best for your material. If your material is a bit broad, it is advisable that you have more than one type of slitting. Most of the jumbo roll slitting machines tend to have at least two types of slitting.

For example, maybe you need a machine that is going to slit adhesive laminate together with a thin film. In this case, your machine should have both the razor and shear. The shear will be for the laminate and the razor being for the film altogether.

There are many other factors and questions regarding the type of slitting to consider for your roll slitting machine. The few above however help you in a great way to understand what you need to help you get started.

How can I maintain my thermal paper roll slitting machine after purchasing?

Proper care and maintenance are necessary for ensuring that your thermal paper roll slitting machine serves you well. The life of your rolling machine is fully dependent on how well you maintain the whole machine. To help you understand better how to take care of your roll slitting machine, we have prepared the guideline below:

- Adding lubrication: You should frequently add lubricating oil to the oil cups, moving surfaces and oil eyes. Due to the extreme friction on the thermal paper roll slitting machine, you should do frequent lubrication.

- Lubrication quantity: You should always ensure you spray the right quantity of lubricating oil on the gear train. The same should be done on the sprocket system. This will make the whole roll slitting machine system run smoothly and evenly.

- Wiping: You must remember to wipe off the residual lubricants that get on the areas not intended for lubrication.

- Fastening: Remember to check any loose areas. If there are loose parts in your roll slitting machine, you should retighten them to avoid any damages and injuries.

- Rubber roller: Avoid making any contact on the rubber roller with the oil used on the thermal paper slitting machine oil.

- Steel roller: Make sure you wipe off the rust from the steel roller. This should also be done on other parts of the roll slitting machine as well.

- Parts maintenance: Cover the electrical control components from shaking and pollution. All the electrical parts should be kept dry and clean at all times.

Apart from the proper care and maintenance, you also need to look out for worn-out parts. The slighter rewinder you bought some years back may have served you so well. But you may notice changes over time and it may just be getting even more.

You may start experiencing reduced overall performance, worn-out replacement parts needing to be changed, and glitches. These are just a few of the warnings and should get you very worried. If you experience any of these, it is time to upgrade your roll slitting machine.

If you had purchased your thermal roll slitting machine from a reliable manufacturer, they may help you. A good roll slitting machine manufacturer can help you upgrade or handle a few if not all replacements.

There are three main types of roll slitting machine equipment that may require an upgrade. They include:

Controls: Your whole system may fail to work if you have a faulty CPU. CPU is part of the programmable logic controller (PLC). You should replace your human-machine interface or operator interface (OI).

This will offer you much better control as well as making the operator’s lives easier. Depending on your specific needs, the HMIs and OIs may come in several screen sizes. They all offer different capabilities to the roll slitting machine.

Drives: For better efficiency and control, you should consider replacing the drives in the entire system. The replacement should be done with variable frequency AC drives. The voltage ranges may vary. However, the most common one is the 480VAC.

Motors: For high energy savings, you should always swap the old motors of your equipment with new ones. This will ultimately result in low energy costs. If you are using DC motors and would want to reduce your energy consumption substantially, switch to AC motors.

AC motors are very efficient. Changing to AC motors may however be expensive. This is because you will also need to have new AC drives too. This is however worth it considering the high efficient functioning that will come about.

Sudden malfunctioning brought about by poor repair and maintenance can be quite inconvenient. Upgrading reduces revenue loss and operational headaches.

Some of the benefits of ensuring proper care and maintenance are done include:

-Increased reliability

-Improved output

-Reduced intervention by the operator

-Great Tension control

-Safer signal voltages on the control

Can one thermal paper slitting machine produce both core rolls and coreless rolls?

Yes, a single thermal paper roll slitting machine can help you produce both the core rolls and the coreless rolls. Earlier roll slitting machines only used to produce one type of roll. For coreless roll slitting machines, they could not produce core roll. When it came to core roll slitting machines, they could not produce coreless rolls.

However, with improved technology and demand from roll slitting machine buyers, a combined machine came up. The combined machine can produce both coreless thermal rolls and core thermal rolls at the same time. The combined two type roll slitting machine saves you money thus increasing your revenue.

Earlier before making this workout, there are a few steps you needed to undertake. You will need to change the shaft. Once you are done producing your coreless thermal rolls, you would need to change the shaft and produce the core rolls.

With today’s technology, you will only need to adjust the tucker and you will be ready to produce core rolls. The tucker is located on top of the thermal paper roll slitting machine.

What are some of the things I should check before calling a roll slitting machine technician?

You should be very careful and quick to notice if there is a problem with your roll slitting machine. The best way to notice an issue with your roll slitting machine is to pay attention to the rewind. Any issues with the slitting machine will be more visually evident on the rewind. Some of the common problems include:

– Soft rolls

– “off core”

– Telescoping rolls

– Edge weave among others

There are a few things you may need to look at before calling a technician for assessment and repair. These include:

– Can you see any job setting? This includes correct tension specifically for the material you are running.

– Is your material good enough? Do you notice any issues with the quality of the material such as too much gauge band?

– Do you have the knives properly sharpened? Have you set the knives correctly in relation to the material you are running?

– Are your rewind shafts working perfectly?

– Can you notice any coatings or inks building up on your rolls? Is the build-up leading to loss of tension and traction?

If you see any of the above issues, you should proceed and call a qualified technician for assistance on the problem.

What are some of the mistakes I may experience when using a roll slitting machine?

Converting a jumbo roll material into smaller rolls can be a huge task. This is especially so if this is your first time operating a new roll slitting machine. No matter the type of material you are dealing with, there are several issues you may run into. Below is a list of common mistakes that can occur and their solutions:

A) Unlike your tight jumbo master roll, your rewind rolls are coming out loose

This is a common issue that gets reported to roll slitting machine manufacturers. As a roll slitting machine seller, we receive this from the first time new buyers. It is important to note that you may need to run the machine a few times before getting all the settings right.

At times, the easiest way to fix this is by getting the settings of your tension adjusted. Other than this, below are a few steps that can fix the issue with your roll slitting machine:

Checking the diameter of your sensors: Most machines will have automatic tension controls. They can read both the diameter of the rewind rolls and that of the unwind rolls. They are able to automatically alter the tensions or torque as both the rewind and the unwind run.

If you have such an automatic roll slitting machine, check the diameter sensor. Confirm that it is well-positioned under or over your unwind roll as well as one of your slit rolls.

Adjust the tension settings: If the sensors are well-positioned and they are accurately capturing the rolls’ diameter, check the tension. Try adjusting the settings of your tension between the rolls. Sometimes doing this during a run may have effects. The rolls may fall over or pop.

Unwind shaft air: If the few options do not lead to a solution, check on your unwind shaft. Make sure that the air shaft contains air inside it. It should hold the unwind roll properly before further checkups.

B) Your material wrinkles as it runs on the slitting blades

Check at the unwind tension: This problem may also be caused by issues with the tension. Apart from the other factors, one main problem can be the unwind tension being set incorrectly. There should be enough as the material goes through the blades. This reduces the likelihood of your material folding along the web path. Loose materials will easily fold across the blades. This results in jagged edges.

Skewed master roll: Another reason can be due to the rewind shaft material being skewed. This means that a given side of the roll is near the blades. Check and ensure that your roll is centrally placed. It should be even all along the shaft.

Check the air inside your unwind shaft: Another faster way is confirming if the roll moving right or left as it gets wound. This movement can be caused by having enough air on the air shaft. As the material is moving, it creates slack inside and may start slitting improperly. During the run, checking the rewind side may show this out.

Maxed out edge guide: All master rolls are not equal. Some will come as straight and also flush from the core all the way to the outer layer of the jumbo roll. Some also come as cone-shaped. If you are working on corn-shaped master rolls, you should first try a reroll. This will help in straightening out your rolls. If the material is coned beyond repair, you should try a new unwind stand or guide with a wide movement range.

C) Poor Quality of Slit Rolls

The blade pressure: Sometimes you may have everything working well but the blades aren’t cutting. In this case, you should check if enough air pressure is being applied to the blades. Lack of enough air pressure being applied on the blades produces very little cut.

Too much pressure can also scratch the anvil shaft’s surface. You should maintain the most appropriate pressure that cuts well. The pressure should also not wear out the anvil shaft, blade holders, or the blade itself.

Improper Slit Method: Different slit methods will produce different qualities for the rolls. Different slitting methods will produce different quality for specific materials. You should discuss your project with your roll slitting machine manufacturer. They will help you understand the blade you need based on the material you have.

D) Your material fails to roll on the core

Buying a roll slitting machine with features such as automatic core placement can come in handy here. This mistake happens frequently if the roll slitting machine lacks automatic placement features. This issue occurs if you place the core wrongly on the shaft. You can place marks alongside the winding position of the material on the shaft.

E) Your material fails to properly slit near the center of your roll

The strongest parts of your roll slitting machine are the anvil shafts. They however have slight malleability. The shaft may at time bend. The bending of the anvil shaft can be brought by:

– The volume of air pressure set for the blades

– Diameter of the blades

– Number of blades in use

– The width of your slits

This mainly occurs to the score blade slitting. One way of preventing this is by working new blades of the entire same diameter. This kills any doubt of having uneven blades. A second way is to have more pressure on the blades based on the pressure gauge requirements.

The last option may be to have the rolls cut into two and running two rolls other than one. You should however ensure that all unused blades are deactivated before trying this. This will reduce some of the pressure that’s on the shaft. If this option fails to yield fruits, consider an anvil shaft with a larger diameter for your roll slitting machine.

In order to let you know more about we Jota company, please watch the following video for reference.

We Jota could also supply the following related machines, if you are also interested in any type, please feel free to send us an inquiry:

- Hot Melt Thermoplastic CFRP CFRTP Prepreg Manufacturing Machine

- Fully Automatic Toilet Paper Maker

- Automatic Facial Tissue Making Machine

- Plastic Film, Fabric, Aluminum Foil Slitting Rewinding Machine

- Paper Sheeter

- Paper Tube Making Machine

- CFRP CFRTP FRP Prepreg Slitter

- Paper Drinking Straws Machine

- Label Die Cutting Machine

- Flexo Printing Machine

- Cardboard Tube Cutting Machine