High Speed Paper Roll To Sheet Rotary Cutter

- Max. 300 cuts/min

- Shaftless unwind stands

- Automatic paper counting

- Automatic sheet stacking

- Specification

- Video

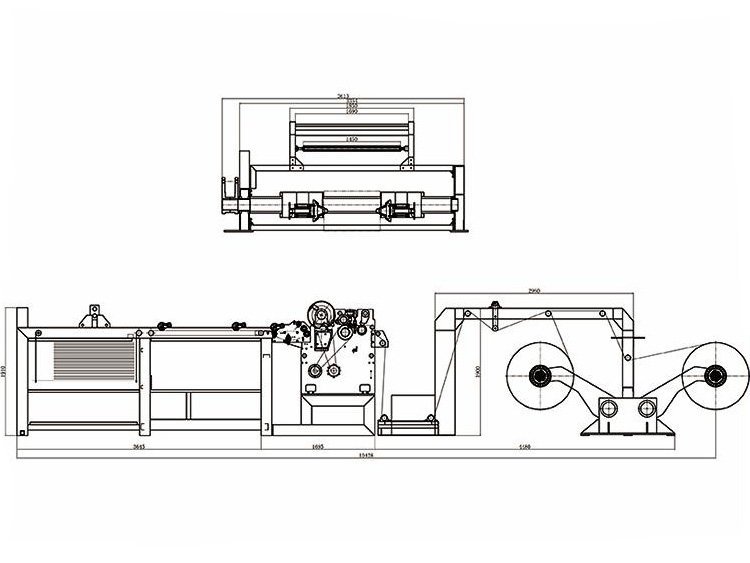

| Parameters | |

| Model | JT-SHT-1700C Paper Roll To Sheet Rotary Cutter |

| Unwinding Width | 1700mm |

| Max. Unwinding Diameter | 1800mm |

| Cutting Length | 450mm-1600mm |

| Format of Slitting | 2 sheets |

| Paper Thickness | 50gsm-550gsm |

| Cutting Way | The upper blade rotates, lower blade is fixed. |

| Max. Cutting Speed | 300cuts/min |

| Max. Stacking Height | 1300mm (51″), it is adjustable |

| Cutting Precision | Cutting Length<1000mm:±0.5mm Cutting Length>1000mm:±0.1% |

| Air Compressor | 0.8Mpa |

| Power | 380V/220V, 50Hz |

| Gross Weight | 10500Kg |

| Specification | ||

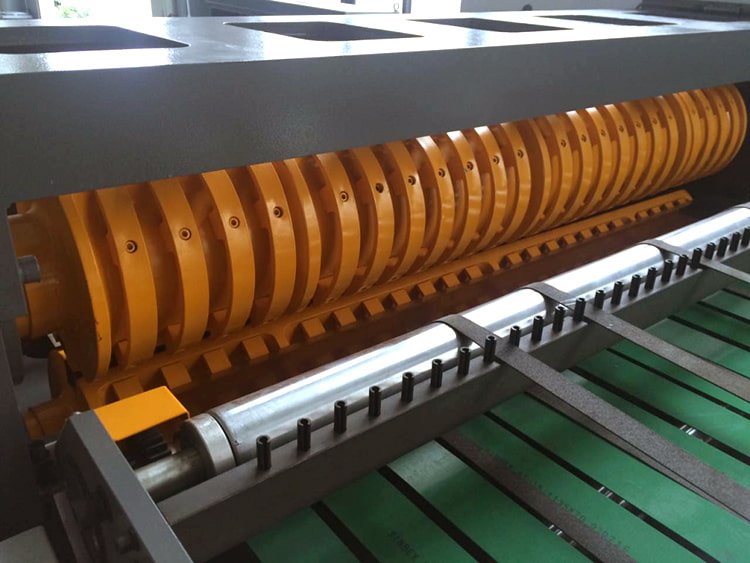

| High precision single rotary blade cutting | ||

| Upper Blade | The cutting way learns from British technology, reduces cutting load and noise effectively, and prolongs blade lifespan. Made by steel welding and precision processing, reduces the shake and noise at high speed after balancing treatment. | |

| Lower Blade | Made by cast iron, then precision processing, with good stability. | |

| Positive Roller | The surface of the roller adopts expansion texture design and the roller is controlled by air cylinder to pressure to clamp paper. | |

| Rotary Blade | Processed by special alloy steel, with a long lifespan. The blade edge is easy to adjust. | |

| Safety Cover | The machine automatically stops when you open the safety cover. | |

| Automatic paper edge adjustment system | ||

| The fixing way learned from British technology, save time and effort, improve efficiency. | ||

| Anti-static device | ||

| Type | Plasma rod to eliminate the static electricity on paper. | |

| Static Elimination Rod | Effective discharge range: 1400mm. | |

| Position | Installed in the middle of the conveyor belt. | |

| Auto meter counter and label inserter | ||

| Type | Precise counting and horizontal insert. | |

| Function | Preset counting No. On-screen and it can insert the label when reaching the preset data. Supply sheet for defect paper. | |

| Conveyor device | ||

| Type | Horizontal and differential speed conveyor (conveyor belt: NITTA from Japan). | |

| The 1st Conveyor Unit | Separate and cut paper rapidly. | |

| The 2nd Conveyor Unit | Independent or linking control to avoid overlap. (synchronic belt: from Ningbo). | |

| Paper Conveyor Unit | The refined paper separator can adjust by paper width. Pressurized conveyor wheel can increase paper stability and avoid excursion. | |

| Auto stacker | ||

| Type | Hydraulic lifting paper stacker, it will automatically fall down when reaching a certain height. | |

| Max. Stacking Height | 1300mm (51”) | |

| Paper Stacking Size | W:1400, L:1600mm | |

| Stacker | Electro-dynamic type for front paper. Pneumatic type for side paper. Adjustable type tailgate. | |

| Computer control system | ||

| Easy operation. Cutting length, quantity, and the total amount can be preset. Actual cutting length and cutting quantity will be shown on the screen. | ||

| Driving motor system | ||

| Configuration | Quantity | Place of Origin |

| AC Servo Drive (Rotary Blade) | 1 | Innovance |

| AC Servo Drive (Conveyor) | 1 | Shanghai Futian Brand |

| Inverter Motor (The 2nd Conveyor Belt) | 1 | Shenzhen |

| AC Motor (Lifting Stacker) | 1 | Shenzhen |

| AC Motor (Front Paper) | 1 | Shenzhen |

| AC Motor (Unwind Stand) | 1 | Nanjing |

| Accessory | ||

| Special Alloy Steel Blade | 1 SET | |

| Label Paper | 10 PCS | |

| Tool Box | 1 SET | |

| Shaftless unwind stand | ||

| Max. Unwind Diameter | 1800mm (71”) | |

| Max. Unwind Width | 500mm-1700mm | |

| Core Diameter | 3”, 6”, 12” | |

Clamp arm can move forward and backward, separate and close, which is driven by a hydraulic cylinder. Clamp arm lifting is controlled by a hydraulic cylinder. The air brake clutch is from Shanghai. Guide roller and related rack. | ||

| Tension control system | ||

| Tension Control System | Pneumatic tension control and pneumatic arm lifting are controlled by dancer roller to adjust the strength of the brake. | |

| Optional | ||

| Optional | One set of slitting blades. | |

| 3 sets slitting knife and waste collection system. | ||

| Vacuum equipment/Anti-dust, which will be installed in the front of the rotary blade to collect the dust on the surface of the paper. | ||

JT-SHT-1700C Paper Roll To Sheet Rotary Cutter

Last Update Time:22/03/2022

Paper roll to sheet rotary cutter is mainly used to cut paper and cardboard sheets, widely used in paper mills, folding carton plant, making carton packaging for pharmaceutical, food, retail, beauty, logistics, and other industries.

Rotary paper cutter mainly has the following advantages.

- High output.

Rotary paper sheeter’s maximum cutting speed can reach 300 cuts/min, if it equips with 2 unwind stands with central slitting, you can cut 1200 sheets per minute, a rotary paper sheeter can cut up to 40 tons of paper a day.

Double rotary knives are optional

- High intelligence degree.

Rotary paper sheeter is controlled by a fully automatic microcomputer and equipped with many auxiliary types of equipment.

Thus, it can reduce the manual operation intensity, such as shaftless unwind stands, automatic angle adjustment, automatic counting, automatic sheet stacking.

In addition to reducing the manual operation intensity, these auxiliary devices have also effectively improved production efficiency.

- The paper converting business is a business with a small investment and high return.

Simply cut the paper to a specific size according to the customer’s requirements, and there is a great return, our customers can recover the cost in 6-8 months at the earliest.

Bhaskar, a guest from Tamil Nadu, India, has been operating a paper converting business in the local area for more than 30 years and is well-known locally.

Bhaskar was originally studying in the United States and settled in the United States for more than 10 years.

In 2015, because he saw that his father was getting old, he had to come back to take over the family business.

Bhaskar first came to China with his dad to purchase equipment in 2016, before then, they had been using a paper roll to sheet cutting machine made in India.

The Indian paper roll to roll cutting machine is very simple and can no longer meet the growing demands of their customers.

Therefore, the father and son decided to purchase a rotary paper cutter machine in China.

They have visited several paper sheets cutting machine manufacturers, and comprehensively assessed the professionalism and language communication comfort of each company.

Yes, language is also an important part of doing business in China, many so-called sales do not understand customers’ ideas, interaction is very tiring.

Also, they compared each supplier’s quality, delivery, and other aspects, finally chose to cooperate with Jota.

Jota CNC Machine

A month later, because Bhaskar had returned to the United States, his old father came to China to inspect the rotary paper sheeter alone.

Considering that his father is over 70 years old, Bhaskar asked us to do him a favor.

His old father set off from Tamil Nadu via Singapore to Pudong, Shanghai, Bhaskar asked us to send someone to pick him up in Pudong, Shanghai, and then take his father to the factory in Wenzhou.

Bhaskar’s father came to China to inspect rotary sheeter machine alone

Bhaskar wants us to take good care of his father along the way.

Our people across the company followed Bhaskar to call him Papa, and the face of Bhaskar’s father blossomed a shiny smile like flowers.

In just one month, we completed the machine delivery within the agreed time, the old man who has more than 30 years of business experience also highly praised us.

The second time I saw Bhaskar, the time has come to 2019.

After taking over the family business for 3 years, Bhaskar has fully mastered the operation of this enterprise.

We met in Guangzhou and enjoyed the famous local breakfast in Guangzhou.

This time, the order he placed was not 1 paper sheeter machine, but 3 sets of 1700C rotary sheet cutter machine.

We are very pleased to see that many customers’ enterprises have completed the inheritance from generation to generation, and they have become bigger and bigger, we are also very happy to develop and grow with our customers.

The story with Bhaskar will be continued.

If you are also interested in getting more info about rotary paper sheeter, please send us an inquiry on our website.

In order to let you know more about we Jota company, please watch the following video for reference.

We Jota could also supply following related machines, if you are also interested in any type, please feel free to send us an inquiry:

- Hot Melt Thermoplastic CFRP CFRTP Prepreg Manufacturing Machine

- Fully Automatic Thermal Paper Roll Slitting Packing Machine

- Fully Automatic Toilet Paper Maker

- Automatic Facial Tissue Making Machine

- Plastic Film, Fabric, Aluminum Foil Slitting Rewinding Machine

- Paper Sheeter

- Paper Tube Making Machine

- CFRP CFRTP FRP Prepreg Slitter

- Paper Drinking Straws Machine

- Label Die Cutting Machine

- Flexo Printing Machine

- Cardboard Tube Cutting Machine