JT-SLT-500B Thermal Cash Register POS Paper Till Roll Making Machine

- 2 Layer carbonless NCR paper rolls production

- 2 independent unwind stand

- 2 sets of fully auto tension controllers.

- Auto cross cutting for cash register end tails

- JT-SLT-500B Thermal Cash Register POS Paper Till Roll Making Machine

- Video

| Max. Unwinding Width | 500mm (600mm customizable) |

| Max. Unwinding Diameter | 900mm |

| Max. Rewinding Diameter | 160mm |

| Min. Slit Width | 25mm |

| Max. Speed | 150m/min |

2 Layers Thermal Cash Register POS Paper Till Roll Making Machine JT-SLT-500B

Last Updated Time:05/11/2022

This JT-SLT-500B two-layer thermal paper till roll making machine is designed specifically for producing carbonless paper rolls, thermal paper rolls, or NCR paper rolls.

As for till roll, it is made from thermal paper, it is mainly applied in the following machines:

- Point of sale (POS) machines

- Credit card machines

- Debit card machines

- Visa card machines

- Adding machines/calculators

- Cash register machines

Till roll is mostly 1-ply, but 2-ply thermal paper till roll can also be found in the Chinese market.

Carbonless paper rolls, on the other hand, are mostly used to print receipts on dot-matrix/impact printers.

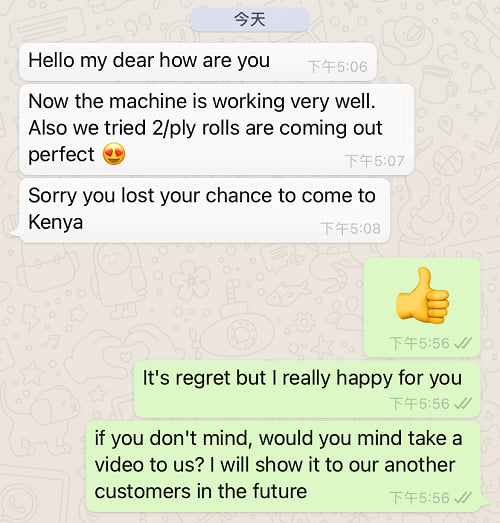

We recently sold a set of 600mm width 2 plies carbonless copy paper slitting machine to a Kenyan customer.

On 11 Jan 2021, we tested this dear Kenya client’s customized thermal roll machine, test video is shown below.

After testing, we shared this video and the below carbonless paper roll photo with Kenya’s client for approval.

Compared with 1 ply thermal paper roll slitting machine, such a carbonless paper roll slitting machine has some unique features.

The independent jumbo roll unwind stand’s quantity is designed according to the ply amount, corresponding amount of tension controller will also be installed accordingly.

Kenya’s client requires two independent tension control units, one of which includes one tension controller and two sensors (hall switches), ensuring sensitive tension sensing and precise tension control.

More drive rollers are required for 2 plies thermal pos paper roll making machine, they are introduced to lead material feeding, take effect on avoiding till roll vibrations.

On Mar 22, 2021, this Kenyan client told us that the 2 plies carbonless copy paper slitting machine worked very well at his place, and he also specially filmed its working video for us.

The working video is shown below:

Compared with the thermal cash register paper roll slitting machine, carbonless paper roll making machine width is mainly 600mm or 500mm for POS paper roll and cash register paper roll.

If you would like to make the 3 layers carbonless paper roll, we Jota suggest you consider about JT-SLT-500 till roll slitting machine.

The narrower the machine is, the smoother the finished roll’s edge, 500mm width machine is more suitable for making qualified till rolls.

3 pies carbonless paper roll slitting is stricter with tension control.

Jota Factory

During the running process, 2 paper jumbo POS paper rolls are unwound from 2 unwind stands respectively, pass through the drive rollers, nip rollers, slitting knives, then finished roll is rewound on rewinding shaft finally.

For more details about this thermal paper roll slitting machine, please feel free to contact us.

As your one-stop shop for thermal cash register paper roll machines, Jota Machinery could sell you the thermal roll machine you need to make POS paper rolls, ATM paper rolls, printer paper rolls, cash register paper rolls, till rolls, etc.

Jota Professional Team

The roots create the fruits, quality is our Jota’s cornerstone, it assists us in gaining trust from customers around the world.

Many clients suddenly contact us for small part replacement after 4-5 years of silence.

Each time we receive such mail, we could feel the client’s satisfaction overflowing from each word.

Saudi Arabia Client Thumbs Up for Jota Thermal Paper Slitter Rewinder

We also supply the inkjet printer for the date coding on the side surface of the thermal rolls. Please check the following video.

Recently, we Jota has just released fully automatic thermal paper roll slitting packing machine JT-SLT-1400FA, from core feeding to finished roll packing, no need dedicated operator, inline printing can also be integrated, please send us an inquiry on this website to get more details.

Thermal Paper Till Roll Making Machine Ultimate FAQ Guide

Thermal Paper

- What Is Thermal Paper Used For?

- What Is The Thermal Paper Price?

- Thermal Paper Manufacturers

- How Can You Tell If Paper Is Thermal?

- How Long Does Thermal Paper Last?

- Is Thermal Paper Bad?

- Does All Thermal Paper Contain BPA?

- Does Thermal Paper Fade?

- How Do You Keep Thermal Receipts From Fading?

- Can Thermal Receipt Paper Be Recycled?

What Is Thermal Paper Used For?

The term “thermal paper” refers to paper that is used to record information and is coated with materials that turn colors when heated.

In other words, thermal paper is a special kind of coated paper that changes the physical or chemical properties of the substance (the color developer) when heat is applied to its surface. This changes the text and image.

Thermal paper can be used as:

- Fax paper, communication carrier for text and graphics on fax machines;

- Recording materials in medical systems, such as ECG drawings;

- Printing paper in Internet terminals;

- Lottery tickets in the betting field;

- Trademarks.

The principle of thermal paper production is to coat fine particle powder on ordinary paper, the particle powder is composed of leuco dye, phenols, or other acidic substances, separated by a film.

Under heated conditions, the film melts and the powder mixes to generate a color reaction.

The text/graphic developed with ordinary thermal paper is unstable and easy to fade, which makes the content illegible and not suitable for long-term storage.

But good thermal paper can be stored for 30 years or even longer.

What Is The Thermal Paper Price?

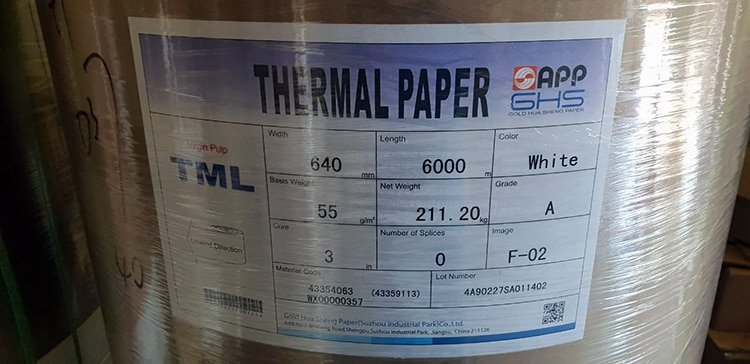

Thermal paper is usually sold per ton.

Because thermal paper is divided into many different specifications according to the paper grammage, the price varies based on different grammage.

The common specifications are:

- 48gsm

- 55gsm

- 65gsm

Moreover, different manufacturers’ thermal POS paper jumbo roll quality is uneven, and the price will vary due to quality differences.

Take the APP brand 55gsm thermal paper as an example, the current price is USD$1,775.00/ton.

APP is the largest pulp and paper mill in Asia and has already ranked among the top 10 in the world.

The APP thermal paper quality is relatively good, if you are more price-sensitive, we can also help you find more competitive price thermal paper jumbo rolls in China.

Thermal Paper Manufacturers

There are many domestic thermal paper manufacturers here in China.

Among which, the larger ones are:

- Jianghe

- Chenming

- Guanhao

- APP

- Xianhe

Well-known thermal paper manufacturers abroad include:

- Germany’s Koehler Paper

- South Korea’s Hansol Paper

- Japan’s Mitsubishi Paper and Ricoh Paper

How Can You Tell If Paper Is Thermal?

We may run into thermal paper in our daily lives.

How can you tell if you have thermal paper?

In fact, the way to do it is very easy.

Scratch the paper gently with your nails, coins, keys, etc., because friction can make heat, and the heat makes the heat-sensitive substance change color.

Therefore, the paper displays traces (usually gray) after being scratched, it is thermal paper.

And the most heat-sensitive paper developer is bisphenol-A.

How Long Does Thermal Paper Last?

Generally, the thermal paper shelf life is only 2-3 years or even a few months.

Long-shelf life thermal paper is classified as long-lasting thermal paper.

At present, the long-lasting thermal paper’s shelf life can reach over 10 years in a normal storage environment.

But the following interference needs to be avoided:

- High temperature

- High humidity

- Direct sunlight

- Contact with solvents, plasticizers

Some particularly good quality thermal papers can even be stored for 30 years.

Is Thermal Paper Bad?

When used in a normal environment and temperature, thermal paper made by regular companies is not toxic. However, if the temperature changes, it will become toxic.

If you can, please wash your hands right away after touching the thermal paper receipt. Do not use alcohol-based cleaners, though.

Do not touch the mouth right away after putting your hands on the receipt.

The thermal POS paper roll contains bisphenol A, although bisphenol A is not a hormone in the true sense, it has a hormone-like effect.

If it is taken in excess, it will interfere with the body’s normal hormone function, affect the reproductive system development, destroy the endocrine system balance.

If there is not much exposure to bisphenol A, there is almost no harm.

Does All Thermal Paper Contain BPA?

Not all thermal paper contains BPA.

Now those thermal paper manufacturers will provide 2 types of thermal paper for customers to choose:

One type is thermal paper with BPA;

The other type is thermal paper without BPA (BPA-free)

The price of thermal paper with BPA is relatively cheaper, and the price of thermal paper without BPA is relatively higher.

You can choose the type you need according to your budget.

Does Thermal Paper Fade?

Thermal paper will fade slowly during storage, which is determined by the thermal paper characteristics, and there is no way to overcome it.

For more important documents, copy the thermal paper and then save, so there are no worries.

How Do You Keep Thermal Receipts From Fading?

Thermal receipts fading can’t be reversed, but you can follow the below precautions to delay thermal receipts fading.

- Protect thermal paper from direct sunlight, moisture, high temperature, and ultra-low temperature.

- Stack thermal paper in layers, avoid too heavy stacking to prevent glue penetration and adhesion.

- Store thermal paper at 23±2℃ and RH65±5% environment.

- Pack and seal the thermal paper with moisture-proof paper or film.

Can Thermal Receipt Paper Be Recycled?

Thermal receipt paper can be recycled by paper recycling plants.

As thermal receipt paper has a layer of chemical raw materials, it must be processed by certain pulping.

Waste collection stations understand more about it than you, they can send waste thermal receipt paper to suitable paper recycling plants.

Thermal Roll

- What Is A Thermal Till Roll?

- What Is The Uses Of Thermal Paper Roll?

- What Is The Difference Between Thermal And Non-Thermal Till Rolls?

- How Do You Measure Till Rolls?

- How Long Is A Roll Of Receipt Paper?

- How Are Thermal Paper Rolls Produced?

- Thermal Paper Rolls Manufacturers

- Thermal cash register paper rolls supplier

What Is A Thermal Till Roll?

Thermal paper till roll is commonly used consumables for cash registers, ATM machines, POS machines, fax machines, and electrocardiographs.

They can be used as carriers to print text and graphics.

Such till rolls are usually made by slitting the thermal paper jumbo roll and then winding it, with a certain width and diameter.

The specific width and diameter can be customized according to the end customer’s requirements.

The most common thermal till roll size is 57mm x 50mm and 80 x 80mm.

What Is The Uses Of Thermal Paper Roll?

Thermal paper has developed rapidly with the fax machine’s popularity all over the world, now its application is becoming more and more extensive.

At present, thermal paper roll’s main applications are listed below:

- Thermal paper for the fax machine

Mainly used for various types of thermal fax machines, this type of fax machine may be used for commercial purposes, or it may be used privately at home.

- Thermal paper for printing and terminal recording

Thermal paper now is quite useful in printing records for many types of equipment.

These equipment include:

- Word processors

- Medical testing and industrial testing

- Computer-aided design and production (maybe CAD/CMA)

- Counters

- Automatic cash payment machines (ATM/CD)

- Portable terminal printers

- Receipt records for highways, and taxis.

- Thermal paper for labels and receipts

The thermal paper application in recent years has been extended to the label field, and the development is fast.

It is a combination of thermal paper and self-adhesive labels, coat the thermal paper’s back with a sticker and compound it on the release paper for labels.

What Is The Difference Between Thermal And Non-Thermal Till Rolls?

- Different printed effect

The thermal paper surface has a special coating, which will turn black when heated.

If it is used as a printing paper, the printed content will disappear quickly;

If the art paper is used as printing paper, the printed content will stay for a long time.

- Different printing methods

One is thermal printing and the other is thermal transfer printing.

- Different quality

The thermal printing paper used in cash registers is generally divided into 3 layers.

The bottom layer is base paper, the 2nd layer is a thermal coating, and the 3rd layer is a protective layer.

The primary influence on its quality is the thermal coating or protective layer, and the plain paper will not be influenced by these 2 factors.

- Different temperature effects

Ordinary paper is less affected by temperature, but the thermal paper is greatly affected by temperature.

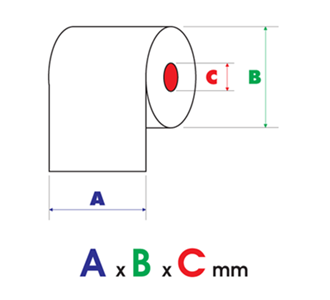

How Do You Measure Till Rolls?

How to calculate till roll length in meters?

Assuming that the till roll length is L(m), the till roll outer diameter is B(mm), the paper core outer diameter is C(mm), and the thermal paper thickness measured by a micrometer is T(μm).

L(length)=(BxB-CxC)x0.7854/T

For example, 57×50 thermal roll, the paper core outer diameter=24mm, the thickness is 78μm.

Then the length L=(2500-576)*0.7854/78=19.37m.

How Long Is A Roll Of Receipt Paper?

Generally speaking, the length of a receipt paper roll is determined by the winding diameter.

The following table summarizes some common receipt paper rolls’ lengths (65gsm):

| Width x Diameter (mm) | Length (m) |

| 57 x 30 | 10 |

| 57 x 40 | 12 |

| 57 x 50 | 20 |

| 80 x 50 | 20 |

| 80 x 60 | 30 |

| 80 x 80 | 60 |

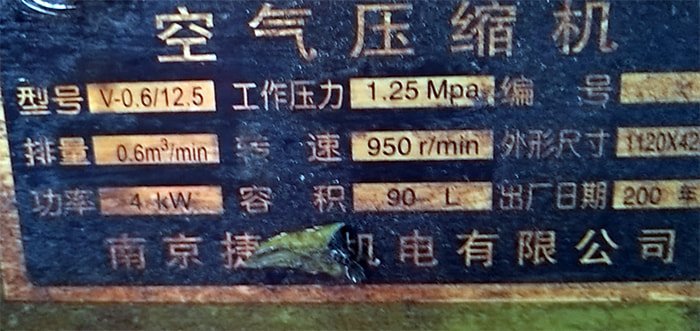

How Are Thermal Paper Rolls Produced?

Thermal paper rolls are produced by a thermal paper slitting and rewinding machine.

Air compressor is also essential because the thermal paper slitting rewinding machine equips with many pneumatic components, such components consume compressed air.

What’s more, thermal paper roll production also requires some necessary raw materials, such as thermal paper jumbo rolls, paper core/plastic core.

Please watch the following video to understand thermal paper roll production better.

Thermal Paper Rolls Manufacturers

China has many thermal paper roll manufacturers, such as:

- DELI

- TANGO

- KONYEE

- GUANHUA

- COMET

- WITEASY

- APP

The above brands are relatively famous.

Regarding foreign thermal paper roll suppliers, you can enter thermal paper roll in the Amazon search bar, many suppliers are listed in front of your eyes.

Some of them are trading companies and some are original factories, you can spend some time and energy to filter or distinguish.

Thermal Cash Register Paper Roll Supplier

There are many thermal cash register paper roll suppliers available. Mainly they have some thermal cash register paper-slitting machines somewhere in the city, they convert the big jumbo rolls into small rolls and then resell them.

Also, you can buy some thermal paper roll slitting machines in your city, then you will be the thermal cash register paper roll supplier.

As we know, there are some big differences in the thermal cash register paper roll prices.

In China and India, the profit is narrow, because there are many peoples in this business. But in some countries of the middle east or Africa. The traditional business is trading. You can easily open a virgin market.

Thermal Roll Making Machine / Thermal Paper Manufacturing Machine

Thermal Paper Manufacturing Process

Thermal paper is a kind of processed paper, and its manufacturing principle is to coat a layer of “heat-sensitive paint” (heat-sensitive color change layer) on high-quality base paper.

Although more than a dozen chemicals are used in this color-changing layer, leuco dyes are essential.

The dye has a wide variety, the most commonly used are fluorescent compounds.

- The developer accounts for about 20% or less

The commonly used are bisphenols and p-hydroxybenzoic acid;

- The sensitizer accounts for about 10% or less

It contains benzenesulfonamides compounds;

- Fillers account for less than 50%

Commonly used is calcium carbonate (fine particles);

- Adhesives account for less than 10%

Such as polyvinyl acetate, stabilizers, dibenzoyl terephthalate, lubricants, etc.

Because of this, thermal paper manufacturing is difficult and the technical requirements are high.

Thermal Paper Roll Manufacturing Process

The production of thermal cash register paper small rolls is realized on the thermal paper slitting machine.

The specific process is to first unwind the thermal cash register paper jumbo rolls from unwind stand, then enter the slitting section after web-feeding through various drive rollers.

The slitting knife divides the thermal paper web into multiple narrow strips.

The narrow strips are wound on a plastic/paper core and then is rolled into a thermal paper roll by shaft rotating.

Thermal Paper Roll Making Machine Manufacturer

Thermal cash register paper rolls making machine manufacturers are available all over the world, these manufacturers are located in the United States, Spain, Italy, Mexico, India, Taiwan, and other countries or regions.

Due to the economic level in different areas, the thermal paper roll-making machine has a big difference in the functions, configurations, and stability.

Mainly, the European and North American machine manufacturer has deep technology accumulations and rich experiences, their machines are with the newest technology, fast speed, and high precision. The big headache is their price is high.

Taiwan’s machine has a good reputation in the world, because of its stable quality and acceptable price.

It could be found mainly in the middle east and south America. But unfortunately, we didn’t see some of Taiwan’s advanced thermal cash register paper roll-making machines overseas.

Machine technology seems like 20 years ago, and it hasn’t been developed anymore. What a pity!

Now More and more customers will choose the Chiese Thermal POS paper roll slitting machine.

The price is acceptable, quality is improving, and technology is the newest one. Just kindly remind, there are many small suppliers or traders in China, and they may not supply a good service to you, please take care!

As a professional maker of thermal paper roll machines in China, Jota Machinery can provide the entire chain of thermal cash register paper rolls, from A to Z.

From the big rolls of thermal paper, the machine for cutting and rewinding thermal paper rolls, and the lines for wrapping up the job. As well as information from a consultant on the global market for thermal paper.

The well-known brands are:

- Jennerjahn in the United States

- Lemu Group in Spain

- LA MECCANICA FUMAGALLI SRL in Italy

As an original thermal paper slitting machine manufacturer, Jota welcomes you to contact us and make a WhatsApp video call with us.

We can show you our factory and CNC machining center in real time.

If you make an appointment, we can also lively broadcast our thermal paper slitting machine’s operation in real-time through WhatsApp video calls.

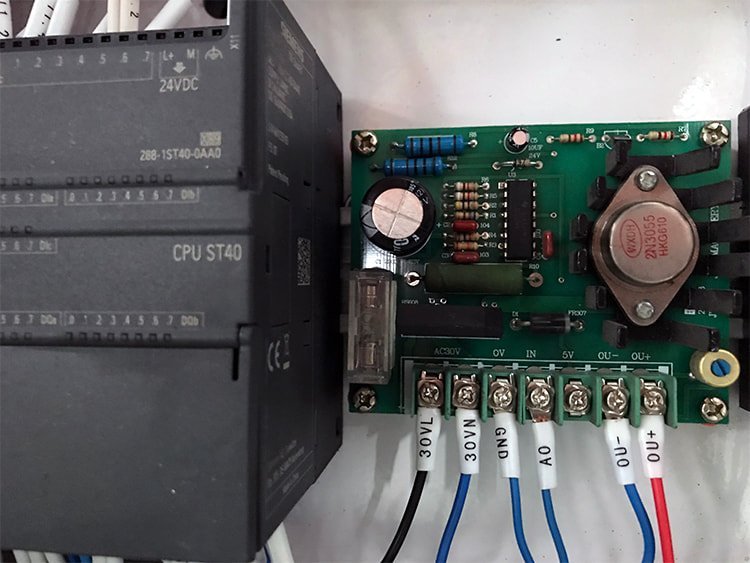

Recently, we have optimized our best-selling JT-SLT-900 thermal till roll making machine.

The wallboard is still as thick as 37mm, the structure is more compact, the tension control function is integrated into the PLC, and the tension control is simpler, more efficient, and stable.

37mm thickness wallboard

Tension control module connected to Siemens ST40 PLC

The optimized JT-SLT-900 thermal till roll making machine’s price is quite competitive now, please send us an inquiry on this website to get more info about it.

What Are The Machine Used To Make Thermal Paper Rolls

The machine used to make thermal paper rolls is a thermal roll making machine, which is mainly composed of an unwinding section, web-feeding section, slitting section, rewinding section, controlling section, etc.

Thermal Paper Roll Making Machine Price

For thermal paper roll making machine, its price mainly depends on the following aspects:

- Unwinding width

At present, the unwinding width of mainstream models is 900mm, but the jumbo roll width in the U.S. and Canadian markets is more than 1300mm, so customers in these markets are in favor of 1400mm thermal paper slitter rewinder;

- Automation degree

The prices of semi-automated and automated machines are definitely different.

If your local labor price is relatively cheap, you can consider semi-automatic machines;

If the labor cost is relatively high, you can consider purchasing fully automatic machines;

- Optional online printing function and packaging lines

If you want to make your thermal paper rolls look more beautiful, you can add the online printing function;

If you want to save labor costs, you can add thermal paper rolls packaging line.

Of course, the price will be much higher after integration.

Thermal Paper Roll Business

- Thermal Paper Roll Business Market Survey

- Thermal Paper Roll Business Profit Evaluation

- Select A Production Site For The Thermal Paper Roll Business

- Thermal Paper Roll Production Equipment And Raw Material Procurement

- Thermal Paper Roll Production Operators Recruitment

- Thermal Paper Roll Business Marketing

- Thermal Paper Small Roll Business Maintenance And Expansion

The use of thermal paper rolls is very wide, many merchants resell and wholesale thermal paper rolls all over the world.

Therefore, now selling thermal paper rolls alone is too competitive and the profit is too low, it is more profitable to set up factories on your own.

Although it is a good idea to set up a small thermal paper roll manufacturing factory, you also need to plan well and implement it step by step, then it is more likely to succeed.

Based on our rich experience in the thermal paper industry, it is recommended that you follow the steps below to engage in the thermal paper roll business.

Thermal Paper Roll Business Market Survey

No matter what business, market demand, and competition are the most important factors affecting success.

Thermal paper rolls are mainly used in POS machines, ATM machines, fax machines, electrocardiograph machines, etc.

These machines are closely related to clothing, food, accommodation, travel, entertainment, medical, office, and other industries, such as:

- Clothing stores

- Shops

- Restaurants

- Catering centers

- Hotels

- Shopping centers

- Supermarkets

- Banks

- Cinemas

If your city or even the entire country is very developed in these industries, it means that your city or the entire country is very needed for thermal rolls, thermal rolls are in great demand.

The next step is to assess the competition degree of the thermal paper roll business in your city or even the entire country.

- Check the Yellow Pages websites

To see how many companies produce thermal paper rolls and select the factories among them;

- Search thermal paper rolls/POS rolls on well-known B2C websites

The search results will list many sellers and filter out the factories among these sellers;

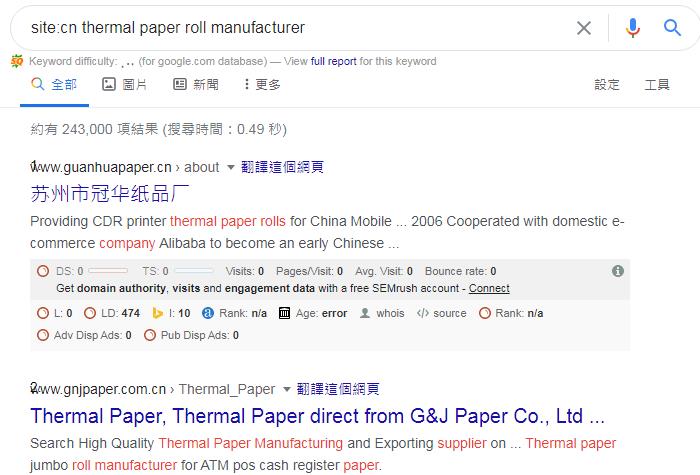

- Enter site: your country’s domain name suffix thermal paper roll manufacturer on Google

If the search results show up, it is usually the original factory for thermal paper rolls.

Even if you find that there are indeed many competitors in your country’s market, don’t worry, because there are usually 2 or 3 major suppliers in a market finally.

You just need to work hard to be one of them.

In order to be successful, you need to use Google to search for more information about the thermal paper roll market in your city and country.

The more information you know, the more likely you are to succeed.

Thermal Paper Roll Business Profit Evaluation

Profit = selling price-cost.

The selling price is calculated by checking the selling price on the local B2C and combining it with the profit rate you want.

As for the cost, it mainly includes the following aspects:

- Raw materials cost, including thermal paper jumbo rolls, paper or plastic cores, packaging carton boxes and films;

- Machine cost, thermal paper slitting machine, air compressor, conveyor belt, packaging line, etc.;

- Import tariffs;

- Factory operating costs (rent, electricity, water, broadband, telephone);

- Labor costs.

After you calculate the profit and the profit meets your psychological expectations, the thermal paper rolls business is worthy of your investment.

According to the experience gained from our past exchanges with old customers, the net profit of the thermal paper roll business can generally reach 10%, the investment recovery period is very short (between 1-2 years), and the return on investment is about 50%.

Select A Production Site For The Thermal Paper Roll Business

After confirming that you want to start your thermal paper roll business, you need to determine the factory location.

- Convenient transportation so that the thermal paper rolls can be transported out;

- Land price is more suitable;

- Far away from residential areas;

- The infrastructure (water, electricity, communications, etc.) must be complete;

- Far away from residential areas;

- Avoid choosing the area of government’s future projects;

- Avoid choosing too remote area, it is difficult to recruit workers.

Thermal Paper Roll Production Equipment And Raw Material Procurement

After addressing the site, the next step is to purchase equipment and raw materials.

The equipment and raw material procurement is based on your personal budget.

If your budget is limited, you can consider purchasing:

- A thermal paper slitting machine

- An air compressor

- 3-5 tons thermal paper jumbo roll

- 100,000 plastic or paper cores

- A certain number of packaging cartons

If you plan to open a medium-scale thermal paper roll factory, you can purchase:

- 5 thermal paper slitting machines

- A flexo printing machine

- 50 tons of thermal paper mother rolls

- 2 million plastic cores or paper cores

- A certain number of packing boxes

If you require a high degree of automation, you can consider purchasing thermal paper roll conveyor belts and packaging lines, from jumbo roll unwinding to small roll packaging.

Now that the Internet is so developed, a large number of machines and raw materials suppliers can be reached.

As long as you are willing to spend the time and energy to communicate, you will surely be able to buy reasonable price machines and raw materials of good quality.

If you feel that your energy and time are limited, you can also contact us and we can recommend suitable machines and raw materials to you.

Thermal Paper Roll Production Operators Recruitment

The ultimate essence of business is always people.

If you can better unite all kinds of talents, you can achieve greater success in your career.

For the thermal paper roll industry, this is no exception.

If you can find one or more excellent operators, he can help you start the machine quickly, and find ways to help you reduce material loss and machine downtime.

No matter what the problem is with the machine, he can help you solve it quickly.

In addition, the thermal paper rolls produced by excellent operators are beautiful and have neat edges.

They can be used well on POS machines, ATM machines, cash registers, and other machines, which can help you more easily win a reputation among end customers.

In order to hire excellent operators, you can provide an attractive high salary, you can also provide a certain percentage of commission according to your small roll order.

Or you can directly give a small proportion of company shares so that he can share the dividends of company development, and make him feel like working for himself.

If you really can’t find a good operator, you can find a novice who is ethical and able to learn first, promise him to be proficient, and then draw a commission according to the small roll order, stimulating his motivation for learning.

Thermal Paper Roll Business Marketing

For the marketing of thermal paper small rolls, one should walk on two legs: online and offline.

- As for online:

I suggest you buildup an official website with your country’s international domain name suffix, customers in your country will feel cordial when they see your website.

In order to make the official website well, you need to design the layout and decoration of the website well.

After finishing it, fill the website with high-quality content that can benefit readers a lot.

The better the content, the better your website can attract potential customers on Google Traffic, and win the inquiries of these potential customers.

- As for offline:

You can search for your local thermal paper small roll wholesalers and distributors, and provide them with small rolls for free at the beginning, and then pay after they sell;

You can print the leaflet or brochure and distribute it to the large shopping malls in your city;

Let the sales staff follow the central commercial street to sell to every merchant store that uses POS machines;

Contact your local POS machines, cash registers, ATM machines, inkless pocket printer distributors, wholesalers, and manufacturers, and ask them to help you bundle thermal paper rolls with the machine to customers;

Print end-customer advertisements on thermal paper rolls, collect advertising fees, and increase the unit price.

Thermal Paper Small Roll Business Maintenance And Expansion

For the maintenance and expansion of the thermal paper roll business, the most important point is to stay focused.

Having been focusing on the thermal paper roll business, you will understand this industry more thoroughly and accumulate more upstream and downstream resources in the thermal paper roll industry.

- In fact, doing business is like planting a tree.

The deeper the root, the more prosperous the branches, the more luxuriant leaves, and the more abundant fruits.

- It’s also like digging a well.

You keep digging and digging, in the beginning, only a little water seeps out, when it reaches a certain point, the water will gush out.

Thermal Paper Till Roll Making Machine FAQ Guide

Due to the high performance of thermal paper till roll making machine and its ability to recycle paper, JOTA is regarded as the fastest developing manufacturer with a global reach.

JOTA designs machines that are worldwide desired due to the advanced technology and multi-functioning.

It is establishing a successful future for your wide range of clients maximizing the industrial competence and technological adeptness of its leaders and team members.

Thermal paper till machine is wide in business, as the world demands toilet paper in bulk.

Let me unravel the important features, working, and details of the till roll making machine.

- What Is a Thermal Paper Till Roll Making Machine?

- How Does the Thermal Paper Till Roll Making Machine Work?

- What Are the Parameters of the Thermal Paper Till Roll Making Machine?

- What Is a Two-layer Thermal Paper Till Roll Making Machine?

- Can I Print with My Thermal Paper Till Roll Making Machine?

- What Is the Use and Characteristics of Thermal Paper Roll in Thermal Paper Till Roll Making Machine?

- What Are the Features of a Till Roll Making Machine?

- What Raw Material Is Needed in a Thermal Paper Manufacturing Machine?

- How Can I Change Till Roll Sizes in a Thermal Paper Till Roll Making Machine?

- What Is the Production Speed of a Thermal Paper Till Roll Making Machine?

- What Are the Applications of a Thermal Till Roll Making Machine?

- What Are the Advantages of Using a Till Machine?

- How Can I Buy a Good Thermal Paper Roll?

- How Are Thermal Paper Rolls Manufactured?

- What Machines Are Suitable for Thermal Paper Production?

- What Is the Difference Between Thermal and Non-Thermal Till Rolls?

- Is Thermal Paper Production Business Profitable?

- How Can I Start, Maintain, and Expand My Thermal Paper Production Business?

- How Can I Find an Authentic Thermal Paper Machine Supplier?

- How Can I Maintain My Till Roll Making Machine?

- Can I Get a Customized Thermal Paper Till Roll Making Machine?

- What Is the Lead Time of Jota Till Machine?

- Does Jota Provide After-Sales Services for Thermal Paper Manufacturing Machine?

- Can I Visit Jota to See the Manufacturing Process of My Thermal Paper Manufacturing Machine?

What Is a Thermal Paper Till Roll Making Machine?

Your thermal paper till roll making machine is usually made up of a number of motors, shafts, PLC modules, automatic tension controllers, and other vital components.

A jumbo roll is un-winded first, then it passes through drive rollers, nip rollers, rotary knives, and ultimately rewound on one shaft to generate narrower reels in the thermal paper slitting rewinding process.

A thermal paper roll till making machine is a type of roll slitting machine that can slit thermal paper jumbo rolls with widths ranging from 400mm to 1400mm into standard 57mm and 80mm width finished till rolls.

Parts of Thermal Paper Till Roll Making Machine

According to their functions, you can separate the thermal paper slitting machines into unwinding, web-feeding, slitting, winding, waste discharging, and control sections, among others.

Purpose

A thermal paper slitting machine is a type of paper slitting rewinding machine that is primarily used for cutting and slitting thermal cash register paper rolls.

For the flexible packaging process, there is a variety of paper cutting and slitting equipment available.

It is made up of the following steps: Slitting – Rewinding – Unwinding – Web guide – NIP roller feeding.

The rewinding shaft, however, is usually a motorized air-expanding shaft or a differential friction shaft. The air shaft can be 3” or 6” in length. The maximum diameter for rewinding is 1500mm.

The new high-intelligence thermal paper slitting machine is improved. It is simple to operate and maintain tasks with the help of Siemens PLC and HMI.

If you would like more professional information on the thermal paper roll cutting machine, then do not hesitate to contact us and submit an inquiry.

Our expert marketing team can provide the entire thermal paper roll converting technology chain. It includes not only a paper slitting rewinding machine, but also raw materials such as thermal paper parents roll, paper core, packaging materials film, carton sealer, and air compressor.

Automatic Working

The paper slitter rewinder is a cutting-edge machine. It’s used to make little slits in a huge paper roll.

You can adjust the width of the slit fit your needs. The procedure begins with the unwinding of a big paper roll.

The paper roll is fed through sharp knives, forming a paper web. Sharp cutters slit the enormous paper web into slits of predefined width.

The slits rotate to make little paper rolls with the help of the rewinding unit.

The slitter rewinder from Jota is a completely automatic machine. The desired data (slit width, unwinding speed, and rewinding speed) can be fed into the HMI PLC control panel.

Thanks to the automatic tension control system, you can easily produce wrinkle-free slit paper rolls.

Slits can be made with gigantic rollers of various sizes. Similarly, depending on your needs, you can make variable-sized slit reels.

CE Certified

Jota ensures to follow the manufacturing standards set by international authorities. The material Jota uses, the techniques to assemble the machine, thorough factory testing, and packaging, everything is up to the mark.

Jota puts your safety at high esteem. For this reason, Jota ensures to makes the machine operator-friendly and safe to use.

Highly qualified team of quality controllers inspects the raw material. After the approval the technicians start the assemblage of till machine.

At every step the QA/QC team checks the standard and perfection. Once the machines is assembled, the engineers conduct a thorough factory test on the till roll making machine.

The machine is tested by running it at a specific speed. Every component is checked for proper functioning. If, needed, innovations are added to improve the functioning.

The machine is tested 4 times. It is tested by the:

- Purchaser

- Assembler

- CNC operator

- Engineers

Many national and international certificates are awarded to Jota till roll making machines. Like:

- Patent certificates

- CE certification

- ISO 9001:2015

- SGS certified

How Does the Thermal Paper Till Roll Making Machine Work?

The master motor in a thermal roll slitting machine rotates the winding shaft and rollers through the timing belt, and the tension created by the rotation rotates the unwinding shaft.

The jumbo roll on the unwinding shaft rolls ahead continuously while the unwinding shaft rotates. After travelling to the slitting section, it is chopped into numerous thermal paper strips by the rotating slitting knives.

The separated thermal paper strips are first glued on the winding shaft, then rotated with the winding shaft to form a finished thermal till roll.

The most significant aspect in the operating procedure of a thermal roll slitting machine is tension management.

The unwinding tension gets smaller and smaller as the unwinding diameter gets smaller and smaller.

At this point, a magnetic powder brake must be installed to improve braking torque and compensate for the decreasing unwinding tension.

The winding tension increases as the diameter of the winding increases.

It’s critical to use a magnetic powder clutch or a manual clutch at this point to reduce braking torque and relieve the increasing winding strain.

So, is the functioning of thermal paper till roll making machine automatic?

Yes, your JOTA till machine is fully automatic.

- The till roll making machine carries all the process by itself thus reduces the aid of manual hard work.

- It has a 1400mm wide surface area for paper roll and works on the speed of 300m/min.

- It has an auto-pushing feature and a core sucker which are used to roll and move the paper.

- It is equipped with sharp cutters and gluing system which are used to cut the paper automatically and glue it.

- It is also used to do finished tail pressing.

- It has an auto roll breakup where it separates and aligns the paper rolls.

- The paper rolls move to the stomper area where hamper and stomper perform their functions automatically.

- The paper rolls transfer to the shrink-packaging area where the till roll making machine packs the manufactured paper rolls.

- You can collect the paper rolls from shrink packager.

What Are the Parameters of the Thermal Paper Till Roll Making Machine?

It is important to know about the parameters of the thermal paper till roll making machine.

The parameters for your till roll making machine are as follows.

- It has 500mm Maximum Unwinding Width (600mm customizable)

- 900mm maximum unwinding diameter

- 160mm maximum rewinding diameter

- Slit Width Minimum of 25mm

- Maximum speed is 150 meters per minute.

However, your POS machine for thermal paper production consists of

- 2 Layer carbonless NCR paper rolls production

- 2 Independent unwind stands

- 2 sets of fully auto tension controllers.

- Auto cross cutting for cash register end tails

What Is a Two-layer Thermal Paper Till Roll Making Machine?

A two-layer thermal paper till roll manufacturing machine can produce carbonless paper rolls, thermal paper rolls, or NCR paper rolls.

The till roll is produced of thermal paper and is used mostly in the following machines:

- POS (point-of-sale) machines

- Machines that accept credit cards

- Machines that accept debit cards

- Machines that accept Visa cards

- Calculators/addition machines

- Machines for counting money

Till rolls are mostly 1 ply, although 2 plies thermal paper till rolls can also be found on the market.

You can also use carbonless paper rolls to print receipts on dot-matrix and impact printers.

A carbonless paper roll slitting machine offers certain distinct advantages over a 1 ply thermal paper roll slitting machine.

The quantity of the independent jumbo roll unwind stand is constructed according to the ply amount, and a corresponding amount tension controller is also provided.

For a 2 plies thermal POS paper roll manufacturing machine, more driving rollers are necessary. They are required in lead material feeding and have an influence on reducing the till roll vibrations.

For POS paper rolls and cash register paper rolls, the width of the carbonless paper roll producing machine is usually 600mm or 500mm.

During the running process, two jumbo POS paper rolls are un-wind from two unwind stands. They pass the through drive rollers, nip rollers, and slitting knives, and then rewound on the rewinding shaft.

For any further information regarding the 2-layerd thermal paper till roll manufacturing machine, you can contact JOTA for assistance.

Can I Print with My Thermal Paper Till Roll Making Machine?

Yes, you can print with your thermal paper till roll manufacturing machine

Thermal printers have been used in the industry for a long time.

They’re frequently utilized in businesses all around the world for a variety of printing operations on paper and other materials.

Because of its low cost, efficiency, high-quality output, and speed, thermal printers have been well appreciated in the industry.

Thermal paper is a recording medium that uses heat from a thermal printer to print.

The designated region of the thermal paper passes over the thermal print head. It creates the picture by heat rather than printing ink.

The image is formed by applying heat (thermal energy) directly to the thermal paper, which contains a coating that turns color to black when exposed to heat.

The thermal paper does not require an ink ribbon, toner, or ink cartridge to record data.

Thermal printing is carried out with inexpensive, portable thermal printers that require little maintenance.

What Is the Use and Characteristics of Thermal Paper Roll in Thermal Paper Till Roll Making Machine?

Thermal paper has grown in popularity as the fax machine has grown in popularity around the world, and its use is now becoming more widespread.

The most common uses for thermal paper rolls are given below.

For the Fax Machine

This sort of fax machine is mostly used for various types of thermal fax machines.

You can use it commercially or privately at home.

For Printing and Terminal Recording

Thermal paper is currently widely used for producing records on a variety of machines.

The following items are included in this equipment:

- Computers with word processors

- Industrial testing and medical testing

- Computer-aided design and manufacturing (CAD/CMA)

- Counters

- Automated teller machines (ATMs) and cash dispensers (CDs)

- Printers for mobile terminals

- Receipts for highways and taxis.

Labels and Receipts

In recent years, the thermal paper application is extended to the label field, and progress is becoming rapid.

It’s a mix of thermal paper and self-adhesive labels, with the back of the thermal paper coated with a sticker and compounded on label release paper.

Characteristics of Thermal Paper

You must consider the following characteristics whilst buying a thermal paper for till roll making machine.

1. How Can I Identify the Thermal Paper?

In everyday life, we have the option of contacting thermal paper; but, how can you verify if you received the thermal paper?

In truth, the procedure is quite straightforward.

Scratch the paper lightly with your fingernails, coins, keys, etc., since friction can generate heat, which allows the heat-sensitive material to acquire color.

As a result, after scratching, the paper leaves traces (typically grey), which indicates that it is thermal paper.

Bisphenol-A is the most heat-sensitive paper’s developer.

2. How Long Does the Thermal Paper Last?

Thermal paper has a shelf life of only 2-3 years or perhaps a few months in most cases.

Thermal paper with a lengthy shelf life is referred to as long-lasting thermal paper.

In a normal storage setting, the shelf life of long-lasting thermal paper can currently reach over ten years.

However, the following interfering factors which you must avoid

- High-temperature environment

- Humidity is high.

- Sunlight in the face

- Solvents and plasticizers come into contact with the skin.

You can preserve the Thermal papers of exceptional quality for up to 30 years.

3. Is Thermal Paper Environment Friendly?

When you use the thermal paper in a normal environment and temperature, it is non-toxic and environment friendly.

But temperature variations render it poisonous.

You must wash your hands as soon as possible after contacting the thermal paper receipt, but do not use alcohol-based cleaning agents.

After your hands have made contact with the receipt, avoid touching your mouth directly.

Bisphenol A is used in the thermal POS thermal paper roll, and while it is not a hormone in the traditional sense, it has a hormone-like effect.

It can also interfere with the body’s normal hormone function, disrupt reproductive system development, and ruin the endocrine system balance if you’ll take in excess.

4. How Can I Prevent My Thermal Paper from Fading?

Thermal paper can fade with time due to the thermal paper’s qualities, and there is no way to avoid this.

You cannot reverse the fading of the thermal papers; however, you can delay it by using the steps listed below.

- You should keep the thermal paper away from direct sunshine, dampness, extreme heat, and extreme cold.

- To avoid glue penetration and adherence, you can stack thermal paper in layers and avoid over-stacking.

- You should store the thermal paper at a temperature of 23±2 with a relative humidity of 65 percent.

- Moisture-proof paper or film should be used to pack and seal thermal paper.

5. Can I Recycle Thermal Paper?

Paper recycling plants can recycle thermal paper.

You should pulp the thermal paper since it contains a coating of chemical raw components.

Waste collection stations are more knowledgeable about collecting the thermal paper for recycling. They can transport waste thermal receipt paper to appropriate paper recycling facilities.

6. Can I Laminate My Thermal Paper?

Yes, you can laminate your thermal paper.

A cold laminate can assist maintain your thermal paper; however, a hot-melt laminate will destroy them rather than preserve them.

Regardless of whether you laminate your receipts or not, they will fade with time.

If you maintain your receipts in a cold, dark environment, lamination will only help them last longer.

7. What Is the Structure a Thermal Paper?

Thermal paper is made out of a base paper and a few different types of coating layers.

The precoat layer and the thermal layer are coated on the recording side’s surface.

8. What Are the Features of a Thermal Paper?

Thermal paper’s primary use is that it is used for thermal printing.

This is why, in addition to standard paper characteristics such as thickness, and strength, thermal printing quality and image stability are crucial.

Furthermore, the thermal paper can become pre-printable using traditional printing methods such as Flexo or Offset.

9. Does Thermal Paper Contain BPA?

No, BPA isn’t found in all thermal papers.

You can now pick between two types of thermal paper from those thermal paper manufacturers:

- One type is BPA-free thermal paper.

- The other variety is BPA-free thermal paper (BPA free)

Thermal paper that contains BPA is less expensive, while thermal paper that does not include BPA is more expensive.

You can select the type you require based on your budget.

10. How Can I Avoid the Exposure of BPA in Thermal Paper?

You can avoid the exposure of BPA in thermal papers in the following ways.

- Request the cashier to place the receipt in the bag.

- After handling receipts, wash your hands thoroughly.

- Ask cashiers to place receipts into a tiny pouch or resealable plastic bag that you keep in your purse.

- Wear nitrile gloves if you operate with thermal paper on a regular basis in your employment to decrease your exposure.

What Are the Features of a Till Roll Making Machine?

In order to make thermal paper rolls from the till roll manufacturing machine, raw materials are also required. Otherwise, you will not be able to run the till roll making machine for thermal paper production

- The following are the most fundamental and raw materials:

- Jumbo roll of thermal roll

- Plastic core and paper core

- Cartons and packing materials (to pack the rolls for shipping).

You’ll need to identify reputable sources for these materials before you start your business.

Only then will you be able to maintain consistent and high-quality manufacturing while also remaining profitable.

If you just have supplier of thermal paper roll raw material, and that supplier runs out of materials or ceases producing for whatever reason (fire, weather, mechanical malfunctions, etc.), your manufacturing will come to a standstill. This will cause you to miss deadlines and lose a significant amount of money.

If you’re interested in purchasing a thermal paper roll production line, please contact JOTA for more information.

What Raw Material Is Needed in a Thermal Paper Manufacturing Machine?

Your thermal paper till roll making machine has the following features

- All winding activities are centralized on one side of the machine for easy and quick action.

- Pneumatic roll lift magnetic particle break marker, speed, length, and stop operations are all controlled by PLC air blowers for removing tim waste.

- Thermal paper production machine is Eco-friendly, abrasion-resistant, wear-resistant and water proof.

- It is also UV proof, anti-static, and has a glossy surface finish.

- Testing processes such as glue and release paper tests are utilized to ensure product quality.

- The till roll manufacturing machine may also be used to make fashionable raincoats and purses, among other things.

- You can further explore the colorful till roll making machine products for scrapbooks and DIY crafts.

- The tapes equipped inside the till roll making machine are single-sided, have sharp edges, and are easily torn.

- You can tailor them according to the individual requirements.

How Can I Change Till Roll Sizes in a Thermal Paper Till Roll Making Machine?

Thermal paper rolls come in a variety of sizes and different countries and areas have varied common sizes.

Thermal paper roll sizes include 56mm x 40mm, 56mm x 60mm, 79mm x 40mm, 79mm x 80mm, and 79mm x 203mm.

The most common thermal paper roll sizes are 57mm x 50mm and 80mm x 80mm.

This is due to the fact that the most popular POS machines and thermal paper printers vary by country and location, and thus the compatible thermal paper roll sizes vary as well.

However, the most widely used thermal paper rolls in the world are still 57mm x 50mm and 80mm x 80mm.

Control Panel HMI/PLC

On the computerized control panel (HMI/PLC) you can conveniently set the sizes of shorter till rolls.

You can change or adjust the size of your thermal paper till rolls from the control panel embedded in the till roll making machine.

So, making variable sized smaller till rolls is not a difficult task. All you need to do is feed the data on the control panel and leave the rest in your thermal paper manufacturing machine.

How can I Measure the Size of Thermal Paper Roll?

You can measure the length of a thermal paper till roll by assuming that the length of the till roll is L(m).

The outer diameter of the till roll is B(mm).

The outer diameter of the paper core is C(mm), and the thickness of the thermal paper measured with a micrometer is T(m).

L(length) = (B x B – C x C) x 0.7854/T

For example, a 5750 thermal roll has an outer diameter of 24mm and a thickness of 78m.

The calculated length becomes L= (2500-576) *0.7854/78=19.37m.

What Is the Production Speed of a Thermal Paper Till Roll Making Machine?

The production speed of your thermal paper till roll manufacturing machine is high.

Its Maximum speed is 150 meters per minute.

The high production speed enhances your business productivity by consuming less time and labor.

Thermal papers have a speed advantage over regular receipt paper in terms of printing time also.

If you want to enhance your store’s service times, investing in a thermal printer and thermal paper is a great way to start.

Lines can move significantly faster at your store if wait times at the cash register are reduced.

You can also improve your company’s customer service quality.

What Are the Applications of a Thermal Till Roll Making Machine?

The till roll is made up of thermal paper and is used in the following machines.

- Point of sale (POS) machines

- Credit card machines

- Debit card machines

- Visa card machines

- Adding machines/calculators

- Cash register machines

- Printing

For masking and sealing reasons, you can use a till roll manufacturing machine.

Hot melt, pressure-sensitive, and water-activated adhesive techniques are used in this process.

These masks and sealing adhere nicely and connect for a longer period of time. You can use this to protect your furniture, walls, and rugs.

They’re simple to use and take off without leaving any residue.

The till making machine a great printability and are ideal for advertising on automobile bodies or billboards. They have excellent graphics and adhere to the surface with ease.

What Are the Advantages of Using a Till Machine?

Till roll making machine is common in the paper converting industry, its other names include

- Thermal paper roll slitting rewinding machine

- Thermal paper slitter rewinder

- Cash register paper roll slitting machine

- POS roll making machine

- ATM roll making machine

It’s commonly used to make miniature thermal rollers.

In the POS roll production machine, jumbo roll thermal paper unwinds from the unwind stand, passes between the drive and NIP rollers, and then passes through the rotary slitting knives.

The wide thermal paper web is slit into many strips, then twisted to paper/plastic cores on the rewinding shaft, forming many pcs until roll.

You can watch the following video for better understanding

Regarding the advantages of Jota till machine, there are several unique selling points that are highly attractive.

- The thermal till roll output is very stable, with an average of 10,000 pcs in 8 hours.

- The machine quality is visible at a glance, baking paint frame, its sickness is up to 37mm. It is strong enough to serve many years.

- You can automatically load or unload the jumbo till roll. This saves labor for your operator.

- Jota bill paper roll making machine equips with proactive lower blades and slave upper blades. This type of shear cutting ensures each small roll edge is smooth and neat. Such small rolls are competitive in the market.

- To eliminate overlapping concerns, the Jota bill paper roll producing machine has a lay-on roller, which allows it to minimize overlapping issues while also reducing material waste to the bare minimum.

- Thermal papers work through heat transmission, which is one of their most distinguishing features. The images are created by inserting heated pins into the paper’s surface.

The advantage of this method is that businesses no longer have to spend money on ink, which is required by traditional printers. For a small business, this means significant cost savings. - The use of ink printers can result in fading of the receipts in some situations. Customers who want to keep their receipts for tax purposes may find this to be an issue.

Companies who want to save money on ink, on the other hand, can use thermal paper.

Your customers may expect receipts that are free of drips and smudges thanks to a thermal printer that transfers heat to the paper.

How Can I Buy a Good Thermal Paper Roll?

Thermal paper rolls are available in a variety of sizes to match a variety of printers and applications. Choosing the correct thermal paper size for thermal paper till roll making machine saves time by preventing you from running out of paper.

Make sure that you get enough thermal paper rolls to cover your requirements.

This way, you’ll have the best chance of earning bulk discounts, which are considerably more cost-effective than regular little orders.

Make sure the thermal paper rolls you purchase are reasonably priced.

You can do so by examining your budget and comparing pricing for paper rolls of comparable quality from various thermal paper machine suppliers.

What Are the Dimensions of a Thermal Till Roll?

The winding diameter determines the length of a receipt paper roll.

The dimensions of various typical paper till rolls are summarized in the table below (65gsm).

| Diameter x Width (mm) | Dimensions (m) |

| 57 x 30 | 10 |

| 57 x 40 | 12 |

| 57 x 50 | 20 |

| 80 x 50 | 20 |

| 80 x 60 | 30 |

| 80 x 80 | 60 |

How Are Thermal Paper Rolls Manufactured?

A thermal paper slicing and rewinding equipment creates thermal paper rolls.

The thermal paper slitting rewinding machine is equipped with various pneumatic components.

Such components consume compressed air. Therefore, an air compressor is also required.

Thermal paper roll manufacturer also necessitates some raw materials, such as jumbo rolls of thermal paper and paper core/plastic core.

Thermal paper is a type of processed paper in which a layer of “heat-sensitive paint” (heat sensitive color changing layer) is applied to a high-quality base paper.

Specifications of the Color-Changing Layer

Leuco dyes are vital in this color-changing layer, which contains more than a dozen compounds.

- The dye comes in a wide range of colors, the most popular of which are fluorescent compounds.

- The developer is responsible for around 20% of the total.

- Bisphenols and p-hydroxybenzoic acid are the most widely used.

- The sensitizer accounts for roughly 10% or less of the total.

- There are benzene sulfonamides in it.

- Fillers make up less than half of the total.

- Calcium carbonate is a common ingredient (fine particles)

- Adhesives make up less than 10% of the total.

- Polyvinyl acetate, stabilizers, dibenzoyl terephthalate, lubricants, and other materials are examples.

Thermal paper manufacturing is difficult as a result of this, and the technological requirements are high.

What Machines Are Suitable for Thermal Paper Production?

Thermal paper rolls are made by a machine called a thermal roll making machine, which consists of several sections, including

- An unwinding section

- A web-feeding section

- A slitting section

- A rewinding section and

- A regulating section.

You can watch the following video in order to enhance your information.

Now the question arises what is the cost of thermal paper till roll making machine?

Cost of Thermal Paper Roll Making Machine

Thermal paper till roll making machine is greatly dependent on the thermal paper till rolls.

Thermal paper till rolls are offered in tons.

Thermal paper is separated into several various specifications based on the grammage of the paper, hence the price changes depending on the grammage.

The following are typical requirements:

- 48gsm

- 55gsm

- 65gsm

Furthermore, the quality of different manufacturers’ thermal POS paper jumbo rolls varies, and the price will change as a result of the quality variances.

A regular thermal paper till roll making machine costs for USD$1,775.00/ton.

The price of a thermal paper roll manufacturing machine is mostly determined by the following factors:

Width of Unwinding

The unwinding width of mainstream models is currently 900mm, but in some countries you can find a 1400 mm thermal paper slitter rewinder.

Degree of Automation

Semi-automated and automated machines have vastly varying pricing.

You may want to explore semi-automatic equipment if the cost of labor in your area is reasonably low.

If labor costs are considerable, you can consider investing in fully automatic devices.

Online Printing and Packing Lines

You can add the online printing function to your thermal paper rolls to make them look more attractive.

You can add a thermal paper rolls packaging line to reduce labor costs.

It can increase the price of your thermal paper till roll manufacturing machine.

What Is the Difference Between Thermal and Non-Thermal Till Rolls?

You can find several differences between the thermal and non-thermal till rolls.

The differences are as follows:

Various Printed Effects

The surface of the thermal paper contains a unique coating that turns black when it is heated.

The printed content can swiftly evaporate if it is utilized as a printing paper.

The printed content will last a long time if art paper is utilized as printing paper.

Various Printing Techniques

Thermal printing and thermal transfer printing are two different types of printing.

Different Levels of Quality

In most cases, the thermal printing paper used in cash registers is separated into three layers.

The base paper is on the bottom layer, the thermal coating is on the second layer, and the protective layer is on the third layer.

The thermal coating or protective layer has the most impact on its quality; plain paper is unaffected by these two elements.

Effects of Various Temperatures

Temperature has less of an impact on ordinary paper, but it has a significant impact on thermal paper.

Is Thermal Paper Production Business Profitable?

What do you need to call a business profitable?

The ratio between the revenue and the expenses determines the profitability of a business. The selling price is computed by comparing it to the selling price on the local B2C market and multiplying it by the desired profit rate.

The cost is mostly comprised of the following elements:

- Cost of raw materials, such as thermal paper jumbo rolls, paper or plastic cores, packaging carton boxes, and films.

- Cost of machinery, such as a thermal paper slitting machine, an air compressor, a conveyor belt, and a packing line;

- Tariffs on imported goods; factory operational costs (rent, energy, water, broadband, and telephone); and labor costs.

The thermal paper rolls business is worth your investment once you compute the earnings and it meets your psychological expectations.

According to our previous interactions with old clients, the net profit of the thermal paper roll company may typically approach 10%, the investment recovery period is short (between 1-2 years), and the return on investment is around 50%.

Expenses of a Till Machine

The expenses of a till machine are:

1. Raw Material

A till roll making machine doesn’t need expensive raw material to manufacture thermal paper rolls.

Thermal paper itself is not an expensive paper.

2. Energy Efficient

Jota thermal paper manufacturing machine is energy efficient and saves you from heavy electricity billing.

3. Operator Friendly

Moreover, you don’t need a great number of operators and staff to handle the working of till roll making machine.

Jota fully automatic thermal paper till roll making machines work on their own once you put in the necessary data in the PLC control panel.

4. Maintenance

Jota provides you exemplary after-sales services. It means that you don’t need to worry about the spare parts and maintenance.

Whenever you find a damaged or malfunctioned component in your till machine, contact Jota, and get a similar component right then.

Similarly, Jota’s engineers and staff are always ready to offer their services for your machine maintenance.

Revenue from a Till Machine

On the other hand, if we talk about the popularity, every industry demands till rolls. More demand means more consumption, and more consumption means more production.

So, the popularity of till rolls is increasing day by day. They are used in:

- Cash registers

- Electronic point of sale printers

Retailers, pharmaceutical companies, industries, food suppliers, and all the industries you can think of, use thermal till rolls.

The price of a thermal till roll of 80 – 120 GSM ranges from 10 – 45 rupees/roll. If you have a 6000m jumbo roll, you can easily make 7000 smaller rolls.

So, just imagine how much profit it generates for you in less than an hour. The fast working of Jota fully automatic thermal paper till roll making machine facilitates you with a fast ROI.

It’s a one-time investment on the machine. Later-on enjoys the perks it provides you with.

How Can I Start, Maintain, and Expand My Thermal Paper Production Business?

Thermal paper rolls have a wide range of applications, and many merchants resell and wholesale thermal paper rolls worldwide.

As a result, because selling thermal paper rolls alone is too competitive and profitable, it is now more advantageous to start your factory.

Although starting a small thermal paper roll manufacturing facility is a fantastic concept, you must plan carefully and implement it step by step for it to succeed.

Based on JOTA’s extensive experience in the thermal paper sector, we recommend you engage in the thermal paper roll business by following the procedures outlined below.

Thermal Paper Roll Business Market Survey

Market demand and competition are the essential elements impacting success in every firm.

Thermal paper rolls are commonly found in POS machines, ATMs, fax machines, and electrocardiograph devices, among other applications.

Clothing, food, lodging, transport, entertainment, medical, office, and other businesses are all affected by these devices, including:

- Shops for clothes

- Restaurants

- Catering establishments

- Hotels

- Shopping malls

- Supermarkets

- Banks

- Cinemas

If your city, or even the entire country, is well-developed in these industries, it suggests that thermal rolls are in high demand in your city or country.

The second stage evaluates the level of competition in the thermal paper roll industry in your area or even across the country.

Even if you discover that your country’s market has many rivals, don’t be concerned. Most markets have only two or three significant suppliers.

To become one of them, all you have to do is put in the effort.

Choose a Manufacturing Location for the Thermal Paper Roll Business

After you’ve decided to start a thermal paper roll business, you’ll need to find a place for your manufacturing.

- The thermal paper rolls are moved out in a convenient manner

- The cost of land is more reasonable

- Located far from any residential zones

- Water, power, communications, and other infrastructure must be completed

- Located far from any residential zones

- Avoid picking a future project area for the government

- Avoid choosing a location that is too remote because it will be challenging to get workers

Thermal Paper Roll Raw Materials

The next stage is to purchase equipment and raw supplies after the site has been addressed.

Your particular budget determines the purchase of equipment and raw materials.

If you have a limited budget, you might want to consider buying:

- A slitting machine for thermal paper

- A compressor for compressed air

- 3-5 tons giant roll of thermal paper

- 100,000 cores (plastic or paper)

- You’ll also need a specific quantity of packaging cartons.

If you want to start a medium-sized thermal paper roll factory, you can get the following items:

- Five slitting machines for thermal paper

- A flexo printing machine is a machine that prints on both sides of a sheet

- Thermal paper mother rolls weighing 50 tons

- 2 million cores (plastic or paper)

There is a specific quantity of packing boxes available.

Thermal paper roll conveyor belts and packaging machines, from jumbo roll unwinding to small roll packaging, are available if you demand a high level of automation.

With the advancement of the Internet, you can contact a considerable number of machine and raw material suppliers.

If you are ready to put up the effort to communicate, you will be able to obtain reasonably priced machines and high-quality raw materials.

If your energy and time are limited, you may also contact us, and we will make recommendations for appropriate machines and raw materials.

Operators Recruitment

Excellent operators make attractive thermal paper rolls with precise edges.

They work well on POS machines, ATMs, cash registers, and other machines and can help you gain a better reputation with your clients.

You can offer an enticing high wage as well as a set proportion of commission based on your little roll order to attract exceptional operators.

You can also offer him a small percentage of company stock to partake in the firm’s growth dividends and feel like he’s working for himself.

Marketing

You can design the layout and decor of the official website correctly to make it successful.

After that, fill the website with high-quality information that will be beneficial to readers.

The better the content, the better your website will attract potential clients on Google Traffic and earn their inquiries.

You can look for local thermal paper small roll wholesalers and distributors, and provide them tiny rolls for free at first, then pay them as they sell;

You can print the flyer or brochure and distribute it to your city’s major retail malls.

Allow salespeople to follow the main commercial street and sell to any merchants who utilize POS equipment.

Enquire with your local POS, cash register, ATM, inkless pocket printer distributors, wholesalers, and manufacturers about bundling thermal paper rolls with the machine for clients.

Maintenance and Expansion

The most critical aspect of maintaining and expanding the thermal paper roll business is to stay focused.

Like every other business, you might come across challenges. Get ready for the challenges and always be positive to take risks.

The more you are bold and ready to take risks, the better you can run your thermal paper production business.

How Can I Find an Authentic Thermal Paper Machine Supplier?

First of all you need to know who is a supplier.

There are numerous thermal paper machine suppliers. They mostly use thermal cash register paper slitting equipment in the city to turn large jumbo rolls into little rolls, which they subsequently resell.

You can also purchase thermal paper roll slitting equipment in your city and become a thermal cash register paper rolls supplier.

When it comes to overseas thermal paper roll suppliers, you can search for them on Amazon.

You can spend some time and effort filtering or distinguish between trading companies and original factories.

Ways to Find an Authentic Supplier

You can find suppliers of till roll making machines worldwide, including the United States, Spain, Italy, Mexico, India, Taiwan, and other countries or regions.

The functions, settings, and stability of the thermal paper roll forming machine vary greatly depending on the economic level in different places.

The majority of European and North American machine manufacturers have extensive knowledge and experience. Their machines are equipped with the most up-to-date technology and great speed and precision.

Their exorbitant price is a major stumbling block.

Due to the consistent quality and reasonable price, Taiwan machines have a solid reputation around the world. They were primarily found in the Middle East and South America.

Customers are increasingly opting for thermal paper for POS machines. The cost is reasonable, the quality is improving, and the technology is cutting-edge.

Authentic manufacturers provide you with these facilities. Contact and meet them.

How?

For this, you need to research well.

Explore the Industrial Clusters

The first and recommended way is to visit the industrial clusters. For example, in China you can find many paper-products related factories in the southeast coastal region.

You can visit multiple factories in different provinces. By comparing the manufacturing processes and the products & services they provide you can finalize the best suited company for your business.

For example, in the Jiangsu province you will find Jota Machinery. It is one of the leading thermal paper machine suppliers in China.

Jota Machinery is a competent thermal paper roll producing machine manufacturer in China. You can get thermal paper jumbo roll slitting and rewinding machines, final wrapping lines, and other machines of your requirement.

Dig in the Web pages

Another way to find an authentic till roll making machine manufacturer is to search the web. Reputed and bona fide companies keep people up-to-date through their official websites.

How?

They give their product lists, specifications of the products, advantages, and uses in multiple industries.

Search Engines

In this way, you can have a clear idea of their company. For example, you can type fully automatic toilet roll making machine in the search pane of Google, Bing, or Yahoo.

You will get hundreds of related results. Go through the top rated websites thoroughly.

You will surely find the one you are looking for.

Social Media Accounts

Similarly, well established companies stay in contact with their stable clients through social media websites.

How?

The company posts about their recent products, upcoming events, launches, and deals & promotions on the social media websites.

For example, you can find authentic manufacturers on Facebook, LinkedIn, Instagram, and YouTube.

Trading Websites

Manufacturers from all over the world showcase their products on trading websites like Alibaba, Aliexpress, DHgate, Made-in-China, and many more.

You can also find a suitable manufacturer and supplier from these websites.

How Can I Maintain My Till Roll Making Machine?

To keep your till roll making machine in good working order, you can follow the steps below.

- Examine every component of your till roll making machine. Look for any missing or broken parts. In moving equipment such as rollers and round disc cutters, check the lubricant levels.

- Complete the checklist in the maintenance handbook for Jota Machinery’s your till roll making machine.

- Dust the rollers and any other necessary item. Avoid bleach and only use the cleaning agents that have been advised.

- It is necessary to clean all of the light surfaces.

- To make the surface more durable, coat it with rustproof oil. Use anti-rust oil if the thermal slitting machine has been idle for a long time.

- Make sure you grease all of the moving part of your till roll making machine.

- Make sure you’re using the right oil for the job and that it’s of good quality. If you use inferior oil, it will cause wear and tear on the moving parts.

- Examine the wiring of all electrical components. Examine any wires that aren’t secure or have come loose from their terminals.