Reputable CFRT/CFRP UD Prepreg Slitting Machine Manufacturer

- More Than 10-Year Experience in CFRT Industry

- Handle Thermoplastic UD & Thermoset Prepreg

- Range from Aerospace to Reinforced Thermoplastic Pipes

- Continuously Improve Composites Machinery Quality

Jota CFRP CFRTP Hot Melt Prepreg Machine

Our Jota CFRP CFRTP prepreg manufacturing machines are ideal machines for CFRP CFRTP prepreg production.

CFRP and CFRTP prepregs are essential raw materials for the production of high-performance carbon fiber and glass fiber composite materials.

If you are looking for prepreg machines, please send us an inquiry on this website.

CFRP CFRTP Prepreg Conversation

Jota Machinery: Your Reliable UD Prepreg Slitting Machine Manufacturer in China

Jota is the original composites manufacturing machine manufacturer here in China.

With our own factory and CNC center, equipment quality could be effectively guaranteed.

Please send us an inquiry to make a WhatsApp video call, let’s show you our real-time factory and CNC center.

Jota CNC Center

Machining Material

- Visible high-quality components.

- Famous brands such as Siemens, Yaskawa, Delta, Schneider, Mitsubishi.

- Self-supporting CNC processed sheet metal, precision parts.

- Assembly raw materials provided by long-term cooperation suppliers.

Installation and operation user manual, wire connection diagram, tension controller guide.

Installation and operation video tutorial.

One-on-one remote video call assistance.

On-site installation and operation guidance.

- Focus Factory

- Dear Customer

- Professional Team

Around 30-45 days, mainly depends on machine type.

Sure, it is our honor to work for you.

We will offer you some parts as backup, in case any part is broken within one year, we will sent you for free.

Sure, if we have client in your country, we will offer.

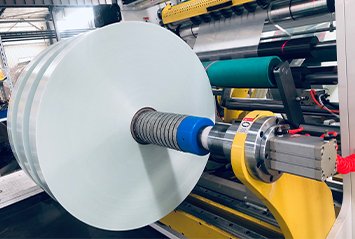

Continuous Fiber Reinforced Thermoplastic Composites UD Prepreg Slitting Machine

Carbon fiber is a crucial material in today’s aerospace & aviation industry, where it’s used extensively in the manufacturing of aircraft and satellites.

Its importance extends into the renewable energy industry, encompassing hydrogen power, solar energy (photovoltaics), and wind energy.

Furthermore, carbon fibers can be processed into specialized products such as thermoplastic unidirectional (UD) Prepreg tape and thermoset carbon fiber prepregs produced using various prepreg machines.

Today Jota Machinery would like to introduce to you the continuous fiber reinforced thermoplastic composites UD prepreg slitting machine used in automated fiber placement(AFP) industry.

After 10 years of continuous growth and discussions on cooperation with airline enterprise, Jota Machinery has become a well-known domestic manufacturer of AFP spooled narrow prepreg.

Because carbon fiber prepreg has the advantages of easy molding, low cost, and easy control of fiber content, it exhibits excellent tensile, stiffness, fatigue, corrosion resistance, and other properties. Therefore, carbon fiber prepreg has been widely used.

The 16-axis UD prepreg slitting traverse spooling machine we developed in 2023 has already assisted customers in their automated fiber placement business, including the Comac C919 aircraft project that was just launched.

Automated Fiber Placement (AFP) is a new composite material manufacturing technology that integrates the attributes of fiber winding and automated tape laying techniques.

The technology precisely positions fibers by controlling the cutting of filament bundles.

It excels not only in laying materials on concave/convex curved surfaces but also in the placement of stiffened plates, parts with variable thickness, and reinforcement around openings.

This advancement has significantly transformed the trajectory of automated tape laying technology.

AFP can meet the variable angle laying requirements of large, complex components with substantial curvature, thereby reducing composite material consumption, and minimizing product waste.

This leads to enhancements in product quality and reliability, ultimately achieving the goal of cost-efficient, high-performance manufacturing for composite material structures.

In industries like aerospace, complex core and essential composite material components can’t be processed manually.

They depend on automated manufacturing equipment such as automated fiber placement machines or automatic tape laying machines.

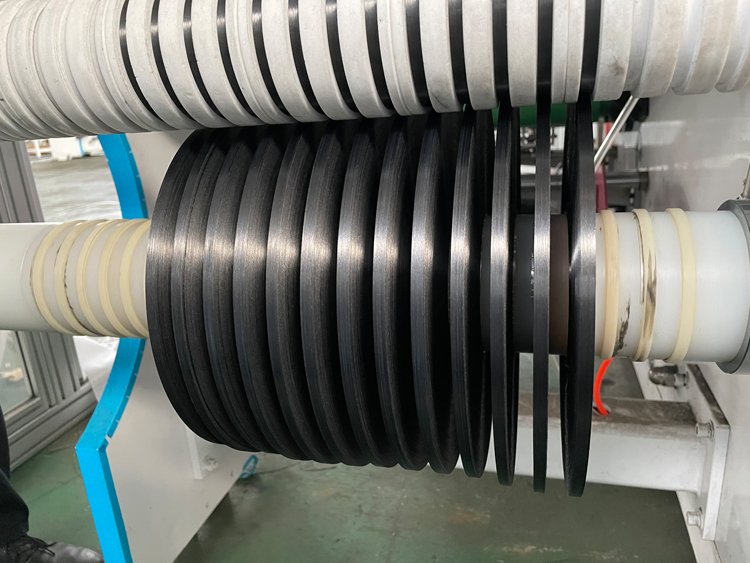

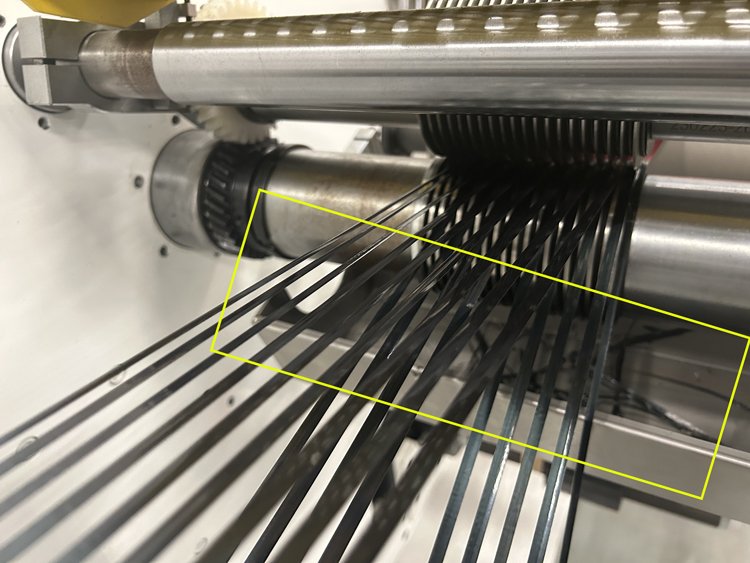

Prepregs for automated fiber placement machines are typically available in widths of 3.175mm (1/8″), 6.35mm (1/4″), or 12.7mm (1/2″), and come in various roll weights.

Narrow spooled prepreg is furnished with a polyethylene protective film and is well-suited for crafting intricate structures with substantial curvatures.

To provide some context before delving into carbon fiber prepreg, let’s begin by explaining what prepreg is.

Prepreg denotes an intermediate composite material comprising reinforcing fibers impregnated with matrix materials.

These matrix materials can include resins, metals, rubber, ceramics, among others.

Reinforcing fibers encompass options like carbon fiber, glass fiber, aramid fiber, basalt fiber, and more.

Carbon fiber prepreg is a thermosetting continuous fiber reinforced composite material that is processed by coating, hot pressing, cooling, laminating, winding and other processes after carbon fiber is fully infiltrated into the resin matrix.

The general width is in the range of 1000-1300mm.

So, what’s the process to reduce this wide prepreg to a 6.35mm width?

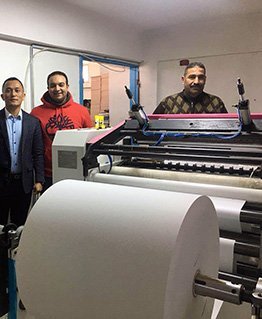

Jota Machinery has introduced 2 sets prepreg slitter rewinder machines to handle this task as part of a comprehensive service.

During a recent exhibition showcasing these two UD slitting machines alongside other equipment for composite materials, the prepreg slitting machine garnered considerable interest from aerospace researchers.

These remarkable scientific researchers are eagerly anticipating our assistance in slitting prepregs to bolster domestic production of large-scale complex composite parts for aviation and aerospace.

After undergoing several enhancements, our pre-slitting machine now efficiently peels off the release paper at the bottom layer of prepreg.

Before this function was added, we all peeled it off manually.

Approximately 2 people are needed to assist in peeling off the release paper when we need to slit prepreg

To speed up the process, we introduced a 3-inch air expanding shaft above the unwinding stand.

This shaft is connected to the motor and operates in a way that mimics a magnetic powder brake. This setup makes it easier to remove the protective release paper.

This operation reduces slitting time by 50% when compared to manually peeling off the release paper.

Furthermore, the slitting machine operator need not worry about stepping on the slippery release paper, minimizing the risk of accidents and injuries.

Prepregs are manufactured using high-cost carbon fibers, including T700, T800, and T1100.

To optimize the utilization of carbon fiber prepregs, our 1100mm width pre-slitting machine is equipped with two 3-inch differential friction shafts.

These shafts not only ensure the neat rewinding of the material but also significantly reduce time in the subsequent slitting process.

The first stage of the process involves the precision cutting of 1100mm-wide carbon fiber-reinforced epoxy resin composite prepreg into widths ranging from 30mm to 300mm.

The subsequent task for the slitting machine operator entails placing the slitted prepreg onto the unwinding stand of the JT-SLT-250S traverse spooling machine.

Following this, the slitter rewinder can remove the surface PE protective film, guide the material into the slitting unit, and conclude the process with traverse spooling.

The resulting narrow prepreg is then ready for testing in the automated fiber placement department.

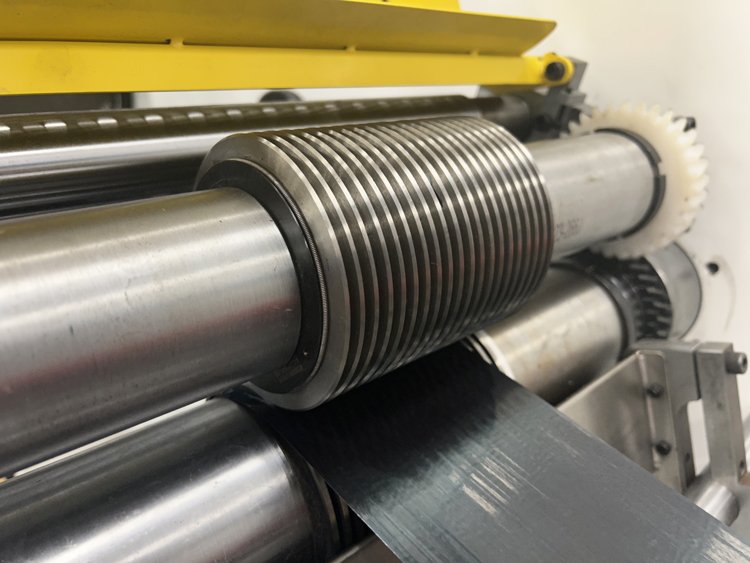

What sets our prepreg slitting machine apart from conventional models is the incorporation of unique anti-adhesion treatments applied to the circular cutters and traction rollers.

We’ve opted for a comprehensive set of circular cutters, featuring different slitting sizes (3.175/6.35/12.7mm) that come pre-fitted with factory-assembled sizes.

This eliminates the need for manual spacer assembly and reduces the risk of losing slitting precision.

The integrated design not only exceeds the international accuracy standard of 0.125mm but has been verified through precise measurement to achieve an exceptional 0.05mm accuracy.

One of the most challenging issues encountered when working with slitted prepreg tape is the notably high viscosity of carbon fiber prepregs.

To address this, our specialized prepreg spreading design and waste edge winding device provide an effective solution.

Preventing the wrap-around of prepreg on the slitting knife mitigates substantial losses and minimizes the risk of subpar output, thus enhancing overall production efficiency.

We have a dedicated tank designed for holding an acetone solution beneath the slitting knife.

This feature simplifies the process for operators to clean the slitting knife.

Jota Machinery recommend you cleaning the knife promptly after completing the slitting process.

The heart of the thermoset prepreg slitter machine lies in its programming, as the program’s operation is intricately linked to the overall production quality.

Our traverse spooling procedure distinguishes itself from conventional practices within the packaging industry. This method is the result of extensive collaboration and modification with numerous scientific researchers.

The capacity for high precision and diverse spooling techniques aligns seamlessly with the requirements of customers who employ automated fiber placement machines.

Jota Machinery’s deep understanding of our customers’ needs has elevated mutual trust to new heights.

While domestic packaging industries may offer similar reciprocating winding equipment, the recognition our equipment garners from renowned companies in the prepreg slitting sector stems from our singular dedication to the slitting industry.

Jota Machinery has worked with materials spanning from paper to continuous fiber-reinforced thermoplastic composites.

We can be recognized because of our rich experience and excellent team.

Our composite material slitting machines at Jota Machinery have undergone continuous improvement.

We have progressed from standard 6.35mm rewinding of carbon fiber-reinforced PEEK unidirectional tape to spool holder rewinding.

For the JT-SLT-900D CFRT fiberglass UD tape slitting machine, we’ve achieved a groundbreaking increase in the maximum rewinding diameter up to 1200mm.

While it may seem like a modest advancement, it reflects our ongoing commitment to self-improvement, pushing boundaries, and rectifying any shortcomings.

In 2023, our proprietary continuous Teflon double belt press machine has made its official debut in the market.

This innovation facilitates the production of lightweight and high-strength products, including PET foam core boards and thermoplastic composite sandwich panels.

Another important aspect is our extensive connections in the CFRT industry.

A decade ago, we initiated partnerships with prominent companies in the continuous fiber-reinforced thermoplastic unidirectional prepreg tape sector, such as Qingdao CIMC, Taishan Fiberglass Inc. (CTG), Weihai Guangwei, and other industry leaders.

Jota Machinery not only offers UD prepreg slitting machines but also provides comprehensive technical support and market planning.

The above constitutes Jota Machinery’s introduction to the two-step production process for AFP prepreg.

If you seek a thermoplastic unidirectional prepreg tape slitting machine or a traverse spooling machine, do not hesitate to reach out to our sales team, who are ready to provide enthusiastic service.