Leading Thermal Paper Slitter Rewinder Machine Manufacturer

- 2 dependent tension controllers for each unwinding stand

- Suits for making 2 layer NCR carbonless copy paper roll

- 3 Layer is also available

- Support customize

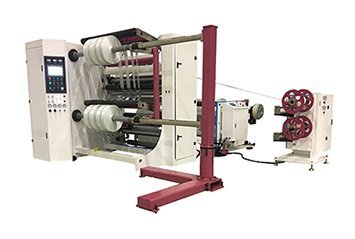

NCR Carbonless Copy Paper Roll Slitting Rewinding Machine

NCR Carbonless Copy Paper Roll Slitting Rewinding Machine is always Jota’s core product from the very beginning.

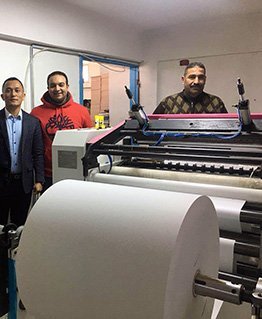

Jota thermal paper slitting machine’s iconic clients include Navigator, SS Labels, K.M.S Group, etc.

When you are shopping in the supermarket or having dinner at a restaurant and swiping your credit card, there is a small cash roll of paper, which is very popular nowadays. It is thermal reception paper or thermal cash register receipt paper. There is a great demand for this kind of paper in the current market, and it penetrates all aspects of your life. Therefore, the thermal paper slitting converting should be a good business for you, it is with a small investment and quick return.

As a professional thermal paper slitter rewinder machine supplier, after 20 years of industry precipitation, we could now provide a full set of thermal paper cashier receipt solutions chain from A to Z, from base thermal paper mother roll, paper core (plastic core), thermal paper slitter rewinder Machine, thermal paper printing machine, cash roll finishing wrapping line, and packaging film, we could provide a full set of professional solutions.

Submit your requirements now, we will recommend a suitable thermal roll slitting machine to you.

Jota Machinery: Your Trustworthy Thermal Paper Slitting Rewinding Supplier in China

Jota is a reliable thermal paper slitter rewinder supplier, we have our own factory and CNC center.

We are able to offer a one-stop solution for your thermal paper roll business.

To OEM your desired thermal paper roll machine, please submit your request to get a quote.

Machining Material

- Visible high-quality components

- Famous brands such as Siemens, Yaskawa, Delta, Schneider, Mitsubishi

- Self-supporting CNC processed sheet metal, precision parts

- Assembly raw materials provided by long-term cooperation suppliers

Installation and operation user manual, wire connection diagram, tension controller guide.

Installation and operation video tutorial.

One-on-one remote video call assistance.

On-site installation and operation guidance.

- Factory

- Customer

- Specs

| Max. Unwinding Width | 500mm |

| Max. Unwinding Diameter | 900mm |

| Max. Rewinding Diameter | 160mm |

| Min. Slitting Width | 25mm |

| Max. Machine Speed | 150m/min |

Around 30-45 days, mainly depends on machine type.

Sure, it is our honor to work for you.

We will offer you some parts as backup, in case any part is broken within one year, we will sent you for free.

Sure, if we have client in your country, we will offer.

NCR Carbonless Copy Paper Roll Slitting Rewinding Machine

Jota machinery is an innovative manufacturer of NCR carbonless copy paper roll slitting rewinding machine.

With 20 years of experience, we have gained trust with some of the most reputable and leading industries globally, such as Sonoco, Mondi, Navigator, and Kurz.

We are a significant exporter of economic and reliable NCR carbonless copy paper roll slitting rewinding machine. Our main products are paper core machines, sheeter, slitter reindeer, and an extensive spectrum of other high-quality products.

With a mission strategy of providing and assisting you in choosing long-lasting machines, we provide a list of commonly asked questions and answers devoted to particularly understanding our products, hence an excellent means of knowing almost all information about our products.

Therefore, to help you make purchasing decisions and further understand our products, these frequently asked questions will help organize information, particularly about our products and services. Have a look.

What are the main products manufactured by Jota?

With NCR carbonless copy paper roll slitting rewinding machine at the top, we offer the best and leading products in thermal slitting winding machines, which include;

- paper tube making machine

- Paper drinking straw machine

- Label Die Cutting Machine

- Automatic Facial Tissue Making Machine

- Slitting Rewinding Machine

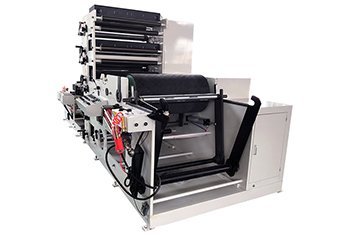

- Flexo Printing Machine

- Cardboard Tube Cutting Machine

- Paper Sheeter

- Fully Automatic Toilet Tissue Paper Roll Making Machine

Two-layer thermal paper till roll making machine, what is it?

The machine produces; thermal paper rolls, NCR carbonless copy paper rolls, and carbonless paper rolls by nature.

Some of the machines produced from the thermal paper till roles include the following;

❖ Machines that accept visa cards.

❖ Counting money machines

❖ Point-on-sales machines (POS)

❖ Machines that accept visa cards

❖ Addition machines (calculators)

❖ Machines that accept credit cards

❖ Carbonless paper rolls are also handy when printing impact printers and dot-matrix.

Carbonless paper roll slitting rewinding machines carry some merits over the one-ply thermal paper roll slitting machine.

The quota of the self-sustaining jumbo roll unwind stand is built following the amount of ply, and the equivalent amount of tension is likewise available.

In the case of a two thermal POS paper roll production machine, extra driving rollers are required.

The extra driving rollers are needed to have an on lowering the vibrations of the till roll and in lead material leading.

For cash register paper rolls and POS paper rolls, the breadth of the carbonless paper roll manufacturing machine ranges between 500mm and 600mm.

During manufacturing, duo jumbo paper rolls are usually un-wind from two unwind platforms.

What happens is that they move via nip rollers, slitting knives, and drive rollers before rewinding on the rewinding shaft.

What are the uses of thermal paper?

Thermal paper is a coated paper that gives thermal energy to the surface, the chemical or physical properties of the color developer are translated to evolve the image and text.

In other words, the thermal paper refers to data recording paper coated with color materials. The materials are brought about by signals from the thermal, which in turn produces colors.

In general, thermal paper is used in the following ways;

- Lottery tickets in the betting field.

- ECG drawings. These are recordings used in the medical systems.

- Trademarks.

- Internal terminals printing papers.

- Fax paper, communication carrier for graphics and texts on fax machines.

Thermal paper manufacturers have a principle of coating pure particle powder joint paper; the particle powder usually contains phenols leuco dye besides various acidic substances separated by some film.

After melting the film under heated circumstances and mixing, it generates a color reaction.

The graphic, or rather the text which is produced by the standard thermal paper, is not stable and, at the same time, quickly fades away.

The fading away tends to make the contents indecipherable, hence cannot be used for long-term storage.

But typically, the best thermal paper can take three decades and beyond in storage.

What are the raw materials used in manufacturing thermal paper rolling machines?

When it comes to thermal paper rolling machines, high-quality raw materials are required, and that is what Jota machinery offers.

These raw materials are as follows;

- Paper core and plastic core

- Parking materials and cartons. The parking materials are for packing the rolls whereby shipping is taking place.

- Jumbo rolls of thermal rolls.

Before starting with your thermal paper business, you will need to get a well-thought source of them.

After identifying the right source of the raw materials, you will be able to maintain a high quality and sustainable production while earning surmountable profits.

Cases may arise where you may not get a constant supply of raw materials because of several things. For example; Your supplier may run out of stock for various reasons; the result is most likely to be a massive loss in earnings.

What are the main features of thermal paper roll-making machines?

This type of machine is attached to some characteristics, these incorporate;

- Apart from being anti-static, the machine is also UV proof and has glossy furnishings.

- You have the choice to tailor the machine depending on your requirements.

- All activities that pertain to winding are concentrated on a single side of the machine for prompt and easy action.

- The tapes within the machine have sharp edges, can easily tear, and are single-sided.

- Pneumatic roll lifts magnetic particle brake speed, length, and halts; every operation is curbed by PLC air whose use is to remove wastes.

- The processes of testing, which include release paper tests and glue, are used to guarantee the quality of the product.

- Another feature of this machine is that it is very friendly to the environment, resists wearing, is abrasion-resistant, and does not allow water inside.

- When it comes to fashion, the machine is not left behind. It makes purses, fashionable raincoats, and other trending things.

Are there any advantages of using a thermal paper rolling machine?

Although this machine will be profitable, it also has some merits attached to it.

- You can comfortably unload or load the jumbo till roll with the machine, which significantly saves on operation labor.

- To terminate overlapping, the machine has a lay-on roller which enables it to reduce any issue to do with overlapping besides reducing any waste associated with it.

- Some situations fading away in the receipts may occur, especially when using the ink printers. That may sometimes end up becoming an issue for clients. Therefore, brands that want to save some ink money can adopt the thermal paper system. Jota thermal paper roll can transfer heat to the paper, which is a plus to many customers because the machine produces receipts that are free from streaks and drips.

- The paper roll-making machine comes with enslaved person upper blades and proactive bottom blades. This kind of shear cutting smoothens the rolled edge and makes it appear neat, making them very competitive in the market.

- The most distinguishing feature of a thermal machine is its ability to function by transmitting heat. Naturally, thermal papers function by heat transmission. The mages are generated by keying heated pins on the paper’s surface. The merit of this method is that enterprises will not need to spend any amount on ink, something which is a requirement of traditional printing.

- The stability of the thermal till roll is sure; that is because it runs an average of 10,000 pcs within 8 hours.

- The quality of the machine is very high, and it is also robust enough to serve for many years on end.

What are the supplemental terms for thermal paper rolling machines?

The machine is familiar in the paper converting industry with extra names, which include;

- POS roll making machine

- Thermal paper slitter rewinder

- ATM roll making machine

- Cash register paper roll slitting machine

What are the charges for the thermal roll-making machine?

There are three main contingents upon which thermal roll-making machines’ price depends. These are;

The degree of automation

Naturally, the prices of both automated and semi-automated machines are unquestionably different.

For instance,

Suppose the price of labor in your locality is high, then you can go for the fully automated machine.

On the other hand, If the labor costs are low, you can choose semi-automatic ones.

They are voluntarily packaging lines and online printing functions.

You are most likely to add some beautiful features for quality and attraction by incorporating some online functions.

You can, however, save on labor costs by including thermal paper rolls packaging lines.

The only slight demerit is that the charges will be high after combining the two aspects.

Unwinding width

As of now, the width of unwinding models works around 900mm; on the other side, the width of jumbo in both Canada and the USA market exceeds 1300mm, meaning the number of customers favoring 1400mm thermal paper rewinder will be high.

Are there any profits attached to the thermal paper roll manufacturer business?

The financial interest, more so, the difference between the amount spent and the amount earned in buying, operating, and the production of the thermal machine, constitutes the profit.

The ratio between the expenses and the revenue determines the profitability of an enterprise.

The selling price is evaluated by comparing the selling price on the regional business-to-customer market before multiplying with the profit rate desired.

Below are the elements which constitute the cost in most cases.

- The machinery costs include an air compressor, packing line, conveyor belt, and thermal paper slitting machine.

- The duty on the goods imported, such as labor costs and operational costs (water, rent, energy, telephone, and broadband)

- The costs of raw materials are films, thermal paper jumbo rolls, packaging carton boxes, and plastic cores or paper.

To be on the safe side, it is vital to take detailed computations in the earnings and try to figure out if it goes hand-in-hand with your psychological expectations.

How can one describe the future of the two-layer thermal paper roll-making machine in Jota?

With technological advancement, Jota thermal machines are facilitated with the latest technologies.

A good example is in our automated thermal machines, which ensures lower factory lead time, shorter workweeks for labor, more efficient use of materials, high rate of production and

increment in productivity, maximum use of floor space, ease of integration with other machines (increased system versatility) –

- Lower changeover time

- Robotic machines can switch between a broad range of products without rebuilding production lines.

- Instantaneous learning of new processes, leading to more improved thermal inventions.

- Flexibility and ease in redeploying new applications.

- Rapid changeover with vision and auto grippers giving room for different shapes and size parts to be part of the same run.

Our engineers are ready to make every other positive move to improve the quality and functionality of the machine to ensure that their clients get the best products.

What is the expatriate level of Jota?

Being an authentic NCR carbonless copy paper roll slitting rewinding machine producer, we can supply you with diverse types of thermal machines.

The reasons that make us stick out and outweigh in the crowd are related to numerous reasons, but to mention a few, we have;

- Staunch and committed customer support – Our professionals fly many hundreds if not thousands of miles to solve your machine problem.

- High-quality 2 layers thermal products – We have had clients who still contact minor components with absolute positive feedback.

- A long time of experience in the production of thermal papers.

- High production standards – we develop international standards like ISO 9001 and certifications.

What is your lead time?

Jota’s trustworthy, trained technicians work together round the clock to ensure that you get your order at the right time.

Our transport partners are very reliable when it comes to shipment; however, a few factors may influence the definite delivery time.

These are;

- Creating a customized machine may demand a longer time.

- If you/your business is within our locality, it will be easier and quicker to receive your products.

- The type of machine, in many cases, determines the lead time.

In general, the moment you have made up your mind on the lead time, it is time to settle how to get your product.