Professional Cardboard Tube Cutting Machine Manufacturer

- Extremely simple and intuitive operation

- Automatic core length measurement

- 2 minutes core size change

- Automatic rotation blades

Cardboard Tube Cutting Machine

Paper tube cutting machine is one of Jota’s hot selling products.

Thailand’s big client Mondi Group has purchased a fully automatic model from us.

Able to get Mondi Group’s trust, Jota paper tube cutting machine is worthy of your trust.

Thailand Iconic Client Mondi Group

Jota Machinery: Original Cardboard Tube Cutting Machine Manufacturer in China

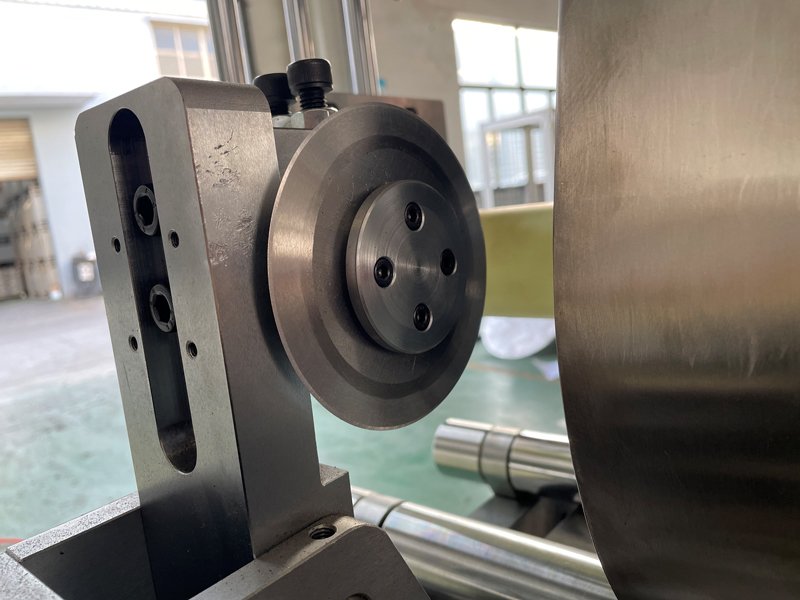

Precision parts’ quality is important for the whole cardboard tube cutting machine.

As we Jota Machinery have our own CNC center, these precision parts could be produced by ourselves.

It is useful for us to control whole paper tube cutting machine quality, ensures it stands your strict inspection.

Jota CNC Center

Machining Material

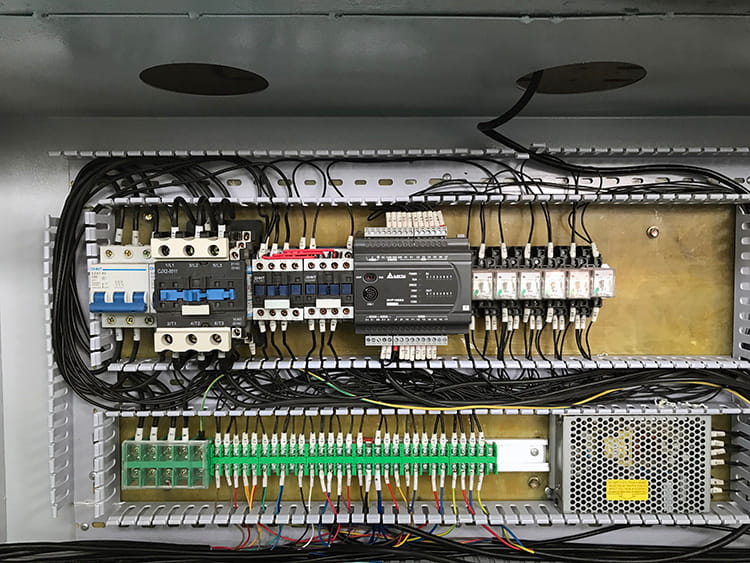

- Visible high-quality components.

- Famous brands such as Siemens, Yaskawa, Delta, Schneider, Mitsubishi.

- Self-supporting CNC processed sheet metal, precision parts.

- Assembly raw materials provided by long-term cooperation suppliers.

Installation and operation user manual, wire connection diagram, tension controller guide.

Installation and operation video tutorial.

One-on-one remote video call assistance.

On-site installation and operation guidance.

- Focus Factory

- Dear Customer

- Professional Team

Around 30-45 days, mainly depends on machine type.

Sure, it is our honor to work for you.

We will offer you some parts as backup, in case any part is broken within one year, we will sent you for free.

Sure, if we have client in your country, we will offer.

Why Jota Cardboard Tube Cutting Machine

Last Update Time: 16/10/2023

Cardboard tube cutting machine generally cuts long paper tubes into many short pieces.

Short pieces of the paper tube could be widely used for rolling different materials, such as paper, label, film, fabric, etc.

In order to meet the different needs of diverse customers, Jota has designed several types of cardboard core cutting machines, according to different automation degrees.

As you have decided to purchase a new paper tube cutting machine, the most important question flashes in your head, where could you get the most suitable cardboard tube cutting tool, or which company’s paper core cutter machine should you buy?

Cardboard core cutting machine being packed for shipment

I suggest you search cardboard tube cutting machine on Youtube, then you could find many videos, these videos are uploaded by different suppliers all over the world.

You could distinguish whose video is HD, smooth streaming, with clear subtitles, contact with such supplier.

After building a connection with a good supplier in cardboard cutting tools, you could request a video call with them.

In this way, you are able to check the supplier’s real factory, watching its cardboard tube cutting tool’s live demonstration.

It will be of great help to you, you are able to cooperate with the real factory.

Jota Factory and CNC Center

The next step is definitely in-depth communication about cardboard core cutting machines.

For the cardboard core cutting machine, several parameters are really important, such as max. tube length, max. tube diameter, max. tube thickness.

Only these parameters are clear in your head, then you could judge which model is best suitable for your choice.

Important Paper Tube Parameters

Of course, you also care about cardboard core cutting machine’s type, features, quality, etc.

According to your different requirements for automation degree, you could choose from:

- Manual cardboard core cutting machine

- Semi-automatic shaftless cardboard core cutting machine

- Fully automatic cardboard core cutting machine

With regard to features, some are helpful for cost-saving, time-saving, labor-saving, productivity-improving.

If your budget is enough, you could pay more attention to Jota’s fully automatic paper tube cutting machine.

As it comes with the fully automatic feature, no dedicated operator is needed, labor cost could be saved.

Besides, such fully automatic cardboard core cutting machine’s working speed is much faster than manual or semi-automatic type cardboard cutting tools.

Faster working speed means high production efficiency, higher production efficiency equals higher profit.

What’s more, to extend blade service life, fully automatic cardboard core cutting machine equips with automatic rotation blade.

The blade rotates a specific angle after each cut, avoids cutting against the tube at a fixed position, extends blade service term, finally saves cost.

Finally, as fully automatic cardboard tube cutting machine comes with finished core collecting trough, you only need to place a big carton box under the trough, watching finished core going into carton box, feels like profit going into your pocket.

Regardless of whether you finally buy paper tube cutting machine from us, you are welcome to communicate with us anytime, one more friend is one more way.

Please send us an inquiry to get a quote, we will reply to you quickly.

![]()

Cardboard Tube Cutting Machine FAQ Guide

Cardboard Tube is a comprehensive product in the industry processing.

You can easily find it in many factories like the plastic film factory, printing house, and some other related industrial product factories.

Not only the paper cardboard tube winding factory needs a tube cutting machine, but also many small factories also need it.

It could help you to cut the long kraft paper tube into small segments for your next working processing.

So you definitely need kraft paper tube cutting tools in your factory, no matter how advanced technology is, you need at least one.

What Is Cardboard Tube?

The cardboard tube is a cylindrical product, it is made by winding multiple plies of kraft paper.

So it is called Kraft Paper Cardboard Tube.

Cardboard tube’s application is very wide, many industries need to use cardboard tube.

- Rolling aluminum foil, thermal paper, non-woven fabric, toilet paper, kitchen towels, wire, etc;

- Making paper cans for different thing’s storage, such as clothes, paintings, maps, cosmetics, foods, and other merchandise;

- Mailing packages;

- Some heavy-duty cardboard tubes can be used to form concrete pillars, and concrete pillars are widely used in the construction or real estate industry.

How Do You Make A Cardboard Tube?

To make kraft paper cardboard tubes for industrial usage, you can consider buying a paper tube winding machine, such machine is also called paper tube making machine, paper core making machine, etc.

For paper tube winding machine, mainly consists of the following sections:

- Unwind stand

- Automatic glue spreader

- Winding and rough cutting

- Controlling

Please watch the following video for reference.

Industrial Cardboard Tubes

Large Cardboard Tubes + Free

Large cardboard tubes are free as a sample, you can judge Jota cardboard tube cutting machine or paper tube winding machine’s quality by judging the large cardboard tube, you just need to undertake the shipping fee to your local place.

Heavy Duty Cardboard Tubes

Kraft Paper Heavy duty cardboard tubes are suitable for storing drawings, posters in shipment, with heavy-duty cardboard tubes’ protection, when mailing precious items, you can prevent them from being scratched or bumped during transportation.

Some netizens give full play to their imagination and come up with many uses of heavy-duty cardboard tubes.

Please refer to the following table:

| Guarding plant |

| Protecting important files |

| Preserving kids’ drawings, artworks |

| Making coffee chairs and lounge tables |

| Storing your clothes |

Heavy duty cardboard tubes are also used in the construction industry, the steel manufacturing industry, or large paper mills.

Generally speaking, the diameter range of heavy duty cardboard tubes is 300mm-600mm, and the maximum thickness can reach 30mm, which is very thick and hard.

We Jota can supply heavy duty cardboard tube winder reeling machine, it uses 4 independent motors to wind the tube;

We can also manufacture heavy duty cardboard tube cutting machine, which uses sawing blades to cut the tube, only sawing can ensure the cut paper tube edge’s smoothness.

If you are interested in these 2 types of machines, please feel free to contact us.

Long Cardboard Tubes

Long cardboard tubes can be used in many places in life, we used to make paper tubes up to 8m long.

On the touch screen of paper tube winding machine, the cardboard tube length can be adjusted as your wish.

However, the long cardboard tube cutting is quite special, and it is generally cut by sawing blade.

Sonoco, the most well-known paper tube manufacturer, has purchased this sawing blade paper tube cutting machine, demo video is shown below.

If you need to cut a long paper tube, please contact us and we will provide you with detailed solutions.

Cardboard Tube Manufacturers

There are various types of cardboard tube manufacturers all over the world.

Generally speaking, paper tube manufacturers need to own 3 machines, a kraft paper slitting rewinding machine, a paper tube winding machine, and a cardboard tube cutting machine.

With these 3 machines, the most basic paper tube can be produced.

Of course, you can also buy multiple machines according to your own requirements for output, 1 slitting machine can match 3 paper core making machines.

However, because your end customers have different requirements for paper tube thickness and diameter, you must choose paper tube machines of different specifications.

As a professional paper tube machinery supplier, we Jota Machinery can provide A-Z solutions.

Jumbo Cardboard Tubes

Jumbo cardboard tubes are generally used to package items and used as mailing tubes, which are widely used in postal and express delivery industries.

Such paper tubes’ diameter is usually 3″ (76mm) and 6″ (152mm), and the thickness range is generally 5mm-15mm.

Because of this, the flexible packaging machines’ unwinding and rewinding shafts are usually 3″ or 6″, such as slitting machines, printing machines, and paper sheet cutter machines.

Cardboard Tubes Packaging

With the improvement of people’s living standards, more and more packaging companies will use cardboard tubes to package products, such as badminton, potato chips, textiles and snacks, and so on.

Cardboard tube packaging has enriched our daily lives and has been favored by more and more customers.

Paper tube packaging is relatively more environmentally friendly, there will be more and more paper tube packaging products in the future.

Now, square tube packaging has appeared on the market.

If you are also interested, welcome to contact us, we have many customers rooted in this field and can provide you with constructive opinions.

Cardboard Core

The cardboard core is used as a sleeve inside the flexible packaging material, then the sleeve is further applied to facilitate the subsequent material processing and transportation.

In addition to paper pipes, we can also see plastic pipes and steel pipes.

The plastic tube material is plastic, which is formed by extrusion or injection;

Steel pipes are used to carry heavy materials.

Thick Wall Cardboard Tubes

Thick wall cardboard tube’s application is mainly reflected in some heavy materials.

Some jumbo rolls materials exceed 500Kg, even reaching 1000Kg, so we need to use thick paper tubes to increase their strength or intensity.

The thicker the paper tube, the more it can withstand high pressure and weight.

Long Cardboard Tubes

Thick Cardboard Tubes

Thick cardboard tubes are related to the amount of kraft paper layers used in paper tube production, a general paper tube is made of about 24 layers of kraft paper.

The kraft paper thickness is 300gsm or 400gsm, after winding 24 layers of kraft paper, tube thickness is up to 15mm.

There are also some very thick paper tubes, the amount of kraft paper layers is 32 or more, and the tube thickness after winding can reach 30mm.

As a professional paper tube machinery manufacturer, Jota Machinery can provide solutions for thick cardboard tubes.

2 Inch Diameter Cardboard Tubes

The 2 inch diameter cardboard tubes are generally used to archive kitchen aluminum foil or cling film, their thickness is less than 5mm, which is relatively light and environmentally friendly.

In kitchenware, the application of 2″ paper tubes is very common.

2″ paper tubes can be produced by our Jota JT-50A paper core making machine.

Long Cardboard Boxes

Long cardboard boxes are mainly with end or side opening, they are generally used as shipping or mailing boxes in logistics, express delivery, postal and other industries.

Industrial Cardboard Tubes

Industrial cardboard tubes have relatively high requirements for hardness.

Heavy industrial products, such as the winding of PET, PVC, PP film;

And some textiles, such as DTY and FTY winding, also have high requirements on the paper tube used for winding.

After some paper tubes are produced, they must be dried in the heat tunnel for more than 12 hours, to achieve the required hardness.

Jota Machinery can provide solutions for paper tube drying.

8 Foot Cardboard Tubes

8 foot cardboard tubes are relatively long, it is widely introduced to forming and construction projects as concrete forming tubes.

With such 8 foot cardboard tubes, concrete contractors and homeowners have an economical way to create round columns.

Column forming tubes are utilized to form round deck supports, lamp posts, structural building supports, etc., and they are made by special moisture-proof kraft paper.

1 Inch Cardboard Tubes

1 inch cardboard tubes are usually used to rewind some small size materials, such as thermal paper (link), SMT spun bond.

The thickness of 1″ paper tube is generally 2mm-3mm, and the commonly used length is 56mm, 79mm, 210mm, 330mm.

The 1″ paper tube used is not as much as the 0.5″ paper tube, but many customers really need such size paper tube.

Large Cardboard Tubes Free

Many large cardboard tubes will be discarded or disposed of after one use.

You can find these large-size paper tubes at the waste disposal station or the warehouse of some large paper mills.

You may only need to pay a small amount when you come across the right size; or if you are lucky, you can get it for free.

Cardboard Cylinder Tubes

Maybe you are looking for cardboard cylinder tubes.

This kind of paper tube is used in many fields, such as food packaging, winding toilet paper, winding kitchen aluminum foil or plastic wrap, etc.

The use of paper tubes is very wide, you need to purchase paper tubes that suit your actual needs, you need to know the paper tube’s inner diameter and thickness before purchasing.

8 Foot Cardboard Tubes

Large Diameter Cardboard Tubes

Many large diameter cardboard tubes are used to make molds for the construction industry, or to rewind and unwind steel.

The large diameter cardboard tubes are very thick and hard and can withstand heavy rolls.

Large diameter paper tubes play an important role in special fields.

30″ Diameter Cardboard Tubes

30″ diameter cardboard tubes are rarely seen in the market, and spiral paper tube winding machines need to be customized to produce 30” paper tubes.

This kind of paper tube can be used for packaging, making paper drums (barrel).

In addition, some people will use a parallel paper cardboard tube machine to make 30″ paper tubes.

1.25 Cardboard Tube

1.25 cardboard tubes can be used to make fireworks or other handmade DIY products.

The 1.25″ paper tube can be purchased directly from the supermarket and is easy to buy.

The thickness of the 1.25″ paper tube is generally no more than 3mm, which is relatively light and suitable for carrying.

Thick Cardboard Tubes

What Can I Make With Thick Cardboard Tubes?

Thick cardboard tubes are useful for storing items in long journey transportation;

Thick cardboard tubes are friendly to environment, they come with durability, stability, and warranty;

Shipping items packaged by thick cardboard tubes or cores will safely reach the final destination without any damage.

Thick Wall Cardboard Tubes

Cardboard tube thickness is generally 5mm-15mm, paper tubes within this thickness range are very common in our daily lives.

Some especially thick wall cardboard tubes’ thickness can reach 30mm, such ultra-thick paper tube will be used in steel mills, large paper mills, or metal smelters.

If you are interested in making thick paper tubes, please inform us of the cardboard tube thickness and inner diameter, and we will recommend a suitable paper core making machine for you.

Cardboard Tube Packaging

Cardboard Tube Packaging Near Me

We always find some packaging cardboard tube suppliers around us.

Such packaging factories generally produce paper tubes themselves, and these packaging factories may also be equipped with subsequent processing equipment for paper tube packaging, such as:

- Curling and grooving machines

- Capping machines

- Labeling machines

Because it has a complete paper tube packaging processing production line, generally all kinds of paper tube packaging can be provided to meet your requirements.

Cardboard Cylinder Packaging

Cardboard cylinder packaging is becoming more and more popular now, and you will find that more and more products around you use paper tube packaging.

First, paper tube can be recycled and will not pollute the environment;

The second is that the high-end paper tube packaging looks more individualized, conforms to some characteristics of the product itself, and improves the grade of the product.

Cardboard Cylinder Tubes

Cardboard cylinder tubes are actually what people often call paper tubes.

The paper tube’s main usage is to wind various flexible materials, such as film, toilet paper, aluminum foil, non-woven fabric, etc.

It can also be used to mail all kinds of goods to avoid damage caused by bumps during transportation, this application is common in postal, express, logistics, and other industries.

Cardboard cylinder tubes can be deeply processed into paper cans, which are used to package tea, candy, chocolate, and other foods, which look high-end and atmospheric.

Eco Friendly Paper Tube Packaging

Paper tube packaging is becoming more and more popular because of its high environmental protection and all materials can be recycled.

The paper tube is mainly made of kraft paper and water-based glue, kraft paper is generally produced after re-pulping recycled paper, and water-based glue is also environmentally friendly.

It is recommended that you use paper tubes as much as possible to replace plastic packaging.

Let us protect the earth we depend on together.

Paper Tube Food Packaging

In supermarkets such as Walmart and Carrefour, you will see that more and more foods are also packaged in paper tubes, this also shows that people’s environmental awareness is increasing.

When packaging food in paper tubes, it is necessary to use aluminum foil at the bottom of the paper tube, and install an additional heating device, make the aluminum foil form a closed can, then meet the requirements of vacuum insulation.

Jota Machinery can provide a complete set of food packaging technology, welcome to contact us.

Cutting Cores

Paper Core Cutter

Paper core cutter is an industrial equipment used to cut paper tubes, it usually cuts long paper tubes or plastic tubes into small paper tubes section by section.

This kind of cardboard tube cutting machine can be divided into manual, semi-automatic, fully automatic types according to automation degree.

Automatic Core Cutter

Automatic core cutter is one type of paper core cutter, because it is fully automatic machine, it has a high automation degree, which can greatly reduce your manual consumption.

Jota automatic paper core cutter machine’s model is JT-SL-2000C, this cardboard core cutter is suitable for cutting paper tubes with inner diameter of 50mm-152mm, thickness of 4mm-15mm, and maximum length of 2000m.

If your paper tube is longer than 2m, we can also customize it according to your requirements.

Manual Core Cutter

Manual core cutter is relatively economical and affordable core cutter machine.

Because it is a manual machine, it requires a dedicated operator to operate the machine.

If your requirements for paper tube output are not too high, and the local labor salary is relatively low, you can consider purchasing this manual machine.

Paper Core Cutter

Manual Paper Core Cutting Machine

Jota manual paper core cutting machine model is JT-600, which is a very simple machine, and the operator can use it in just 5-10 minutes.

The standard configuration of this machine is to support 600mm long paper tubes, but it can be customized according to your requirements and supports cutting longer length paper tubes.

Automatic Paper Core Cutting Machine

The automatic paper core cutting machine only needs the operator to place the long paper tube on the rack before the machine starts running, then start the machine, and the rest of the work is done by the automatic paper tube cutting machine.

Therefore, as long as you own this automatic cardboard core cutting machine, the production efficiency of paper tubes will be greatly improved, and you can save a lot of labor costs.

Paper Core Cutting Machine Price

Paper core cutter machine price ranges from USD$2000 to USD$30000 according to different types of models, the higher the cardboard core cutting machine’s automation degree, the higher the price will be.

Paper Core Cutter Blades

Paper core cutter blades are used too frequently, so the breakage rate is relatively high, and the high breakage rate of consumables will also increase your production costs.

So when you purchase paper core cutter, pay special attention to the material of paper core cutter blades.

The blade of Jota automatic paper core cutter rotates a certain angle after each cut, which greatly extends the service life of the cutter blades.

Paper Core Making Machine

Paper core making machine is mainly used to produce long paper tubes.

Usually, many layers of kraft paper are glued with water-based glue and then wound together to form a thick paper tube.

In order to recommend suitable paper core making machine for you, you need to know what specifications of paper tube you want to produce, such as paper tube length, paper tube inner diameter, paper tube thickness, etc.

- If you want to produce paper tubes with thickness of 0.6mm-5mm, inner diameter of 10mm-120mm, and length of 500mm-2000mm, you can consider our JT-50A paper core making machine;

- If you want to produce paper tubes with thickness of 1mm-10mm, inner diameter of 20mm-156mm, and length of 500mm-4000mm, you can consider our JT-120A paper tube making machine;

- If you want to produce paper tubes with thickness of 1mm-18mm, inner diameter of 20mm-250mm, and length of 500mm-5000mm, you can consider our JT-200A paper core winding machine.

In order to let you know more about we Jota company, please watch the following video for reference.

We Jota could also supply following related machines, if you are also interested in any type, please feel free to send us an inquiry:

- Hot Melt Thermoplastic CFRP CFRTP Prepreg Manufacturing Machine

- Automatic Facial Tissue Making Machine

- Fully Automatic Toilet Paper Maker

- Fully Automatic Thermal Paper Roll Slitting Packing Machine

- Plastic Film, Fabric, Aluminum Foil Slitting Rewinding Machine

- Paper Sheeter

- Paper Tube Making Machine

- CFRP CFRTP FRP Prepreg Slitter

- Paper Drinking Straws Machine

- Label Die Cutting Machine

- Flexo Printing Machine