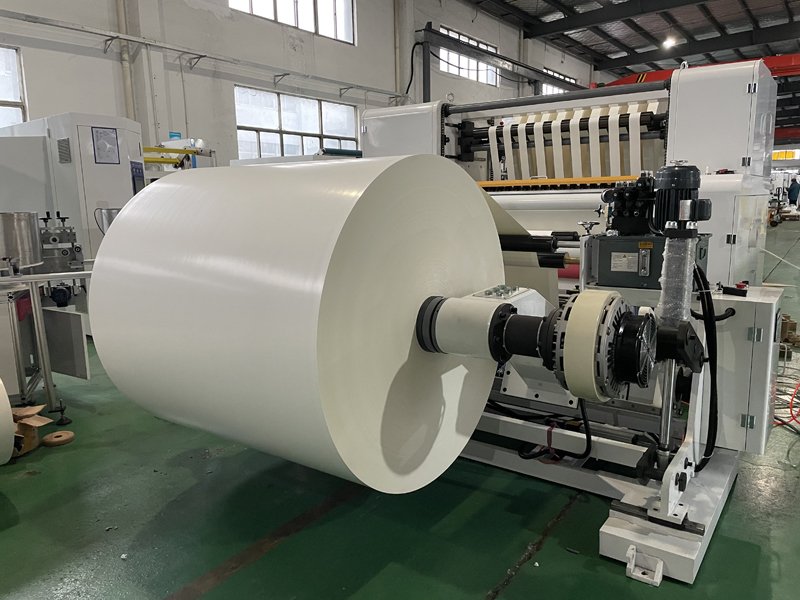

JT-SLT-1300C Paper Film Slitting Rewinding Machine

- Automatic pneumatic loading system from Taiwan

- Siemens PLC control and 7” graphic HMI

- 3 asynchronized servo motor and 3 Yaskawa AC drive

- Edge Position Controller (Web Guiding)

- Specification

- Video

Parameters

| Max. Unwinding Width | 1300mm |

| Max. Unwinding Diameter | 1500mm |

| Max. Rewinding Diameter | 1000mm |

| Min. Slitting Width | Round Blade: 30mm |

| Acceptable Thickness Range | Paper: 40gsm-500gsm |

| Max. Machine Speed | 300m/min |

| Unwinding/Rewinding Shaft | 3’’ (76mm) air expanding shaft |

| Rated Power | 22Kw |

| Machine Weight | 3500Kg |

| Overall Dimensions | 3600mm*2600mm*2000mm |

| Specifications |

| JT-SLT-1300C paper film slitting rewinding machine is able to many kinds of material, such as plastic film (PVC, PET), kraft paper, aluminum foil, non-woven fabric, etc. |

| Siemens PLC control system and 7” Hightech graphic HMI, all the parameters are shown on the screen. Just set up roll diameter, material thickness, original tension…, then the machine works automatically. |

| 3 sets asynchronized servo motor and 3 sets Yaskawa AC drive. |

| Automatically pneumatic material loading, convenient and labor-saving. |

| Ultrasonic web guiding system, its high sensitivity maintains the material at the required position. |

| Electromagnetic brake for unwinding tension control. |

| Embedded encoder in asynchronized servo motor for rewinding tension control. |

| Automatic finished reel discharge. |

| Dynamic / static balancing transmission shafts. |

| Automatic rotary encoder metering slit length. |

| Emergency switch. |

| Waste removal system. |

JT-SLT-1300C Paper Film Slitting Rewinding Machine

Shot on 23rd Jan 2022

Shot on 23rd Jan 2022

Last update time:15/11/2022

Late in January 2022, a customer from the Philippines bought our JT-SLT-1300C Paper Film Slitting Rewinding machine.

He sent us two rolls of laminated paper jumbo roll for paper cups so we could test his slitting machine.

We should slit the paper into 69mm and 62mm widths according to their requirements, and the maximum rewinding needs to reach 1000mm.

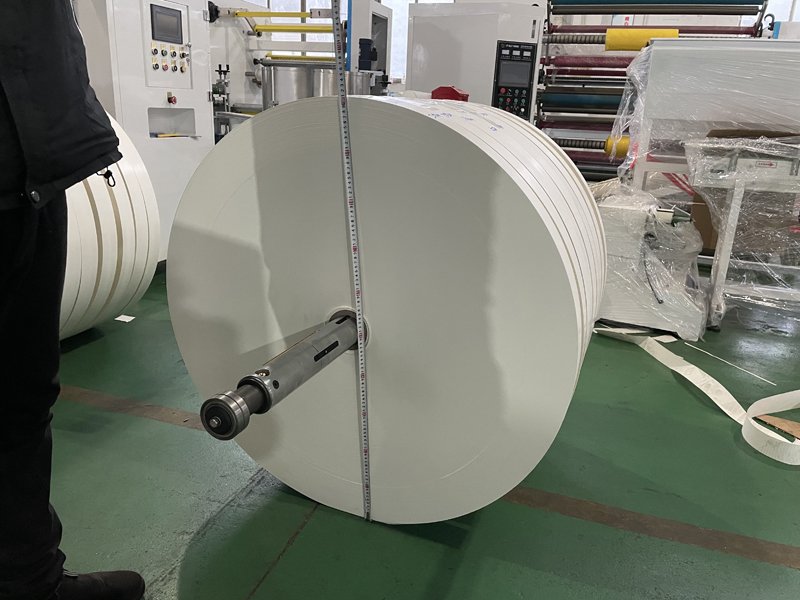

The laminated paper has been slitted

We have completed the cutting of the material according to the customer’s requirements as scheduled and sent it to the Philippines together with the equipment

JT-SLT-1300C Paper Film Slitting Rewinding Machine

After measuring the diameter is already over 1000mm

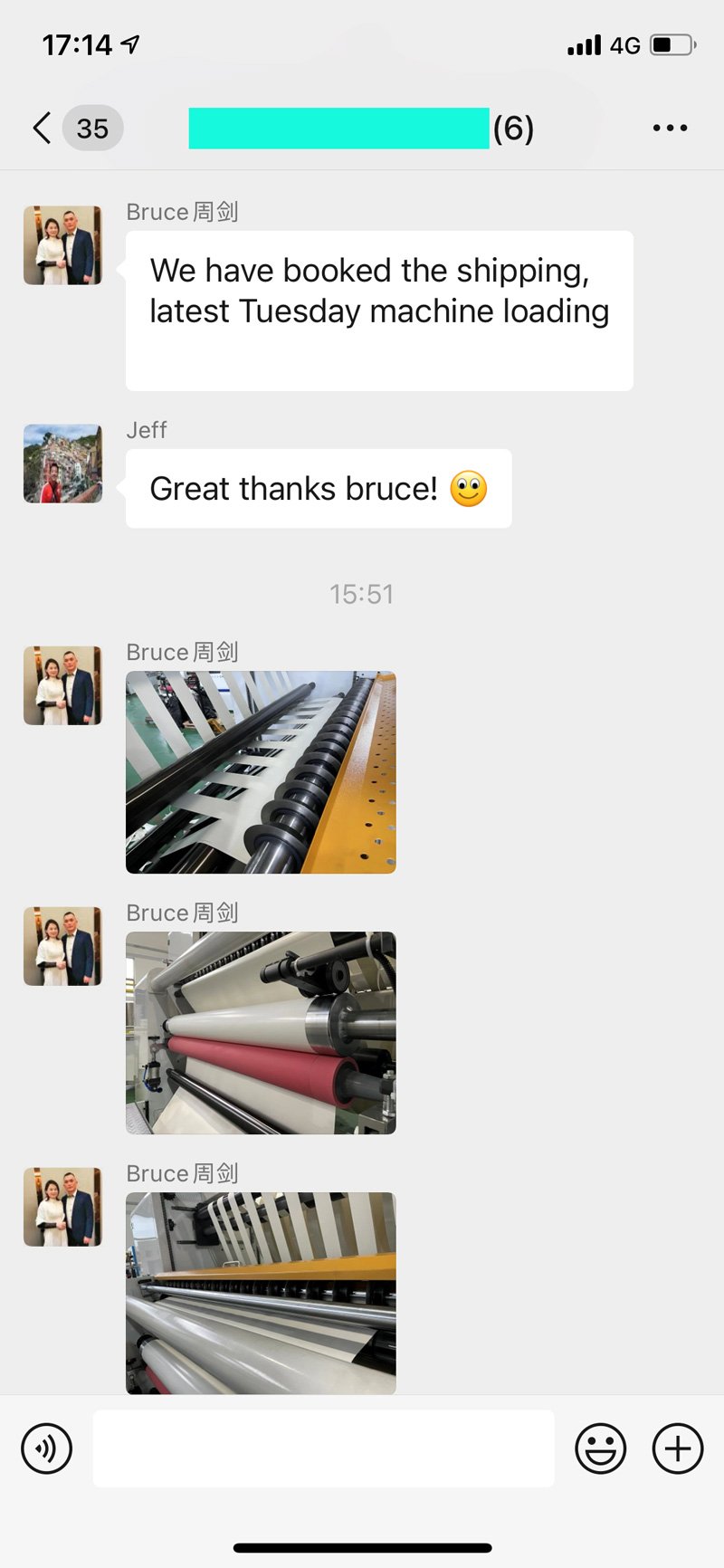

His slitting machine will go to load on the 25th of January

This is mainly because of Jota’s technological progress, and China’s spare parts supply chain’s continuous improvement.

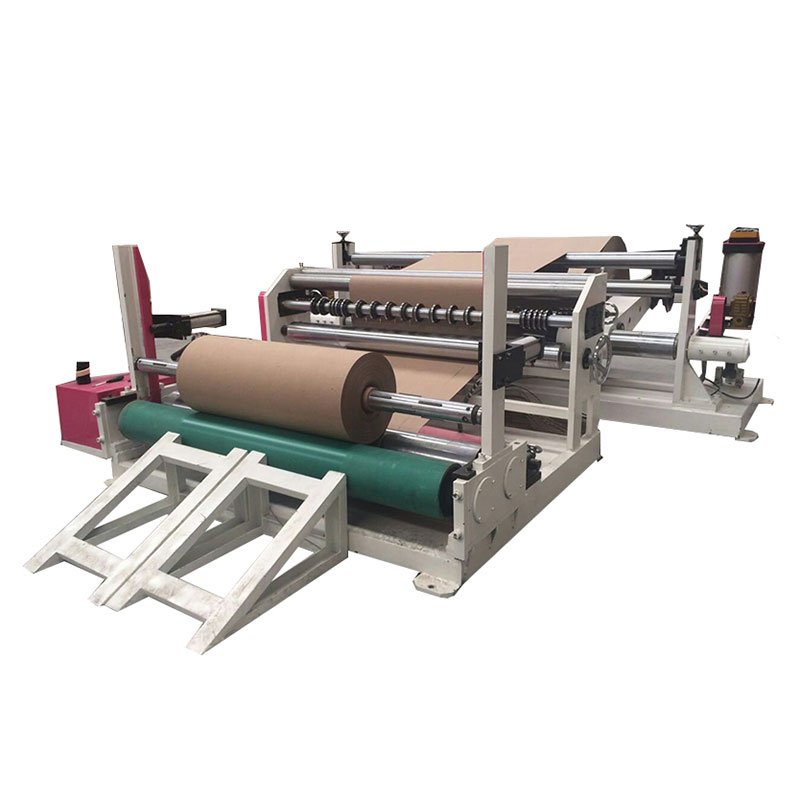

In 2010, the main economical paper slitting machine promoted by Jota was still the JT-SLT-1300.

JT-SLT-1300 paper slitting machine’s main color was blue, it creatively used 2 inverter motors to drive material feeding, slitting knife blade rotating, and rewinding.

JT-SLT-1300 Paper Slitting Machine

And the tension control of rewinding is realized by electromagnetic clutches.

Due to the use of double electromagnetic clutches, rewinding tension is well controlled, and finally leads to a good winding effect.

So, the JT-SLT-1300 paper slitter was sold all over the world and exported to Egypt, Greece, Macedonia, Russia, Romania, Zimbabwe, South Korea, Spain, Argentina, etc.

Later, with the advancement of slitting and rewinding technology, Jota Machinery developed the JT-SLT-1300C paper slitter rewinder machine, an upgraded version of the economical JT-SLT-1300 slitting and rewinding machine.

The upgraded JT-SLT-1300C is equipped with three asynchronous servo motors (with embedded encoder) and three variable-frequency drives.

Asynchronous Servo Motors

Yaskawa Variable-frequency Drive

One motor is used as the main motor to control the material feeding, the other two motors control the winding shaft, and all the motors are controlled by Siemens PLC.

Siemens PLC

The tension during the machine running period is kept more stable, and the winding effect is better.

For processing materials such as paperboard, cup bottom paper, box paper, wrapping paper, and kraft paper, the upgraded JT-SLT-1300C paper roll slitting machine could handle them with ease.

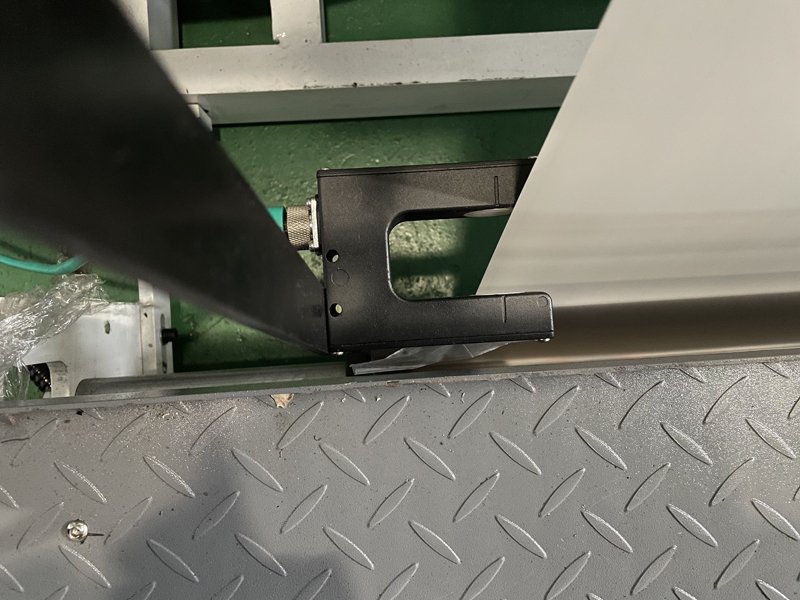

Because the material used for the upper round knife is HSS, 140mm in diameter; and the material used for the lower round knife is also HSS, 100mm in diameter.

Upper and Lower Slitting Knives

The maximum speed of the JT-SLT-1300 paper roll slitter could reach 300m/min, and the rewinding diameter is up to 1000mm.

Russian customer Alexander purchased an upgraded JT-SLT-1300C paper slitter rewinder for processing single or double side PE coated paper and kraft paper because Alexander’s business covers A4 paper, paper tubes, and paper bags.

Before sending the machine to Alexander, we tested it and shot the following testing video:

Egyptian customer Hassan previously traded in China, then he made up his decision to switch the runway in 2014, and open his own factory. He also bought a 1300C paper slitting and rewinding machine from Jota after a deep discussion with Jota boss Bruce.

Joint Photo of Dear Client Hassan and Jota Boss Bruce

Hassan’s factory converts the mother rolls of plastic films such as PVC and PET into small rolls and then converts them into plastic sheets by a cross-cutting sheeter machine.

After years of hard work, Hassan now is the No.1 plastic sheet supplier in the Egyptian market.

The Netherlands client also purchased 1 sets of JT-SLT-1300C non woven fabric slitting machine from Jota. On 9 Jul 2020, the machine is ready for shipment. We Jota carefully packed the machine, and just waited for the container to load and ship out.

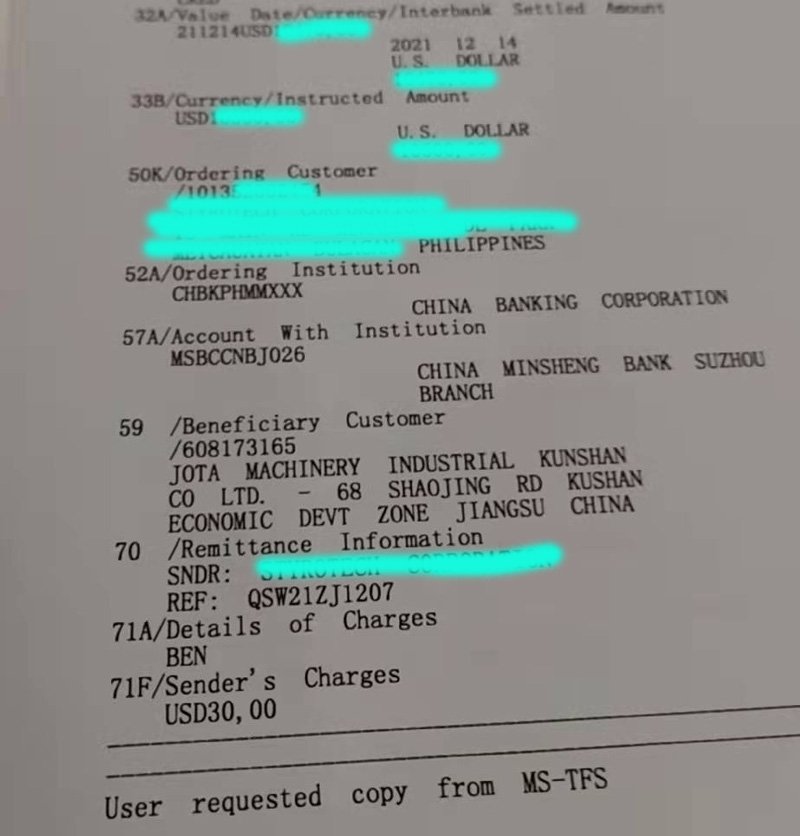

On 15/12/2021 We received the deposit from Philippine Client

Hassan, Alexander, and the client from the Netherlands are all willing to choose Jota’s JT-SLT-1300C paper roll slitter rewinder, indicating that they endorse this machine in their hearts and that many of its selling points are both eye-catching and endearing to them.

1. Automatic pneumatic feeding system: it could realize fully automatic jumbo roll loading, reduce the labor intensity of workers and improve production efficiency, stable performance, reliable use, and low failure rate.

2. Web guiding system (EPC: edge position controller): its high sensitivity maintains the material at the required position, ensures that the material enters the predetermined cutting position accurately, improves the cutting accuracy, and reduces the waste of material.

Ultrasonic Sensor

3. Automatic finished reel discharge: it’s easier for the operator to unload the terminal roll because the finished small roll could be lifted down by the motor-driven chain.

The following machine presentation video includes the content of the finished reel discharge, please watch it for reference.

Of course, there are still some secrets about the machine, which may be exactly what you care about, and this article does not mention it, then please send us an inquiry to explain your requirements for the machine.

We will get in touch with you as soon as possible, and discuss the customization of your desired duplex slitter rewinder machine.

In order to let you know more about we Jota company, please watch the following video for reference.

We Jota could also supply the following related machines, if you are also interested in any type, please feel free to send us an inquiry:

- Hot Melt Thermoplastic CFRP CFRTP Prepreg Manufacturing Machine

- Fully Automatic Thermal Paper Roll Slitting Packing Machine

- Fully Automatic Toilet Paper Maker

- Automatic Facial Tissue Making Machine

- Paper Sheeter

- Paper Tube Making Machine

- CFRP CFRTP FRP Prepreg Slitter

- Paper Drinking Straws Machine

- Label Die Cutting Machine

- Flexo Printing Machine

- Cardboard Tube Cutting Machine