JT-SLT-1300F Multi-Functional Slitter Rewinder

- PLC control and HMI interface

- Yaskawa frequency inverter

- Double Siemens inverter motors

- Hydraulic jumbo roll loading

- Specification

- Operation Manual

- Video

| Max. Unwinding Width | 1300mm |

| Max. Unwinding Diameter | 800mm |

| Max. Rewinding Diameter | 800mm |

| Slit Width | 30mm-1300mm |

| Acceptable Thickness Range | 50gsm-800gsm |

| Max. Machine Speed | 300m/min |

| Unwinding/Rewinding Shaft | 3’’ (76mm) air expanding shaft |

| Rated Power | 18Kw |

| Wall Thickness | 50mm |

| Unwinding Stand | Air expanding shaft or shaftless |

| Rewinding Shafts | Differential friction shaft is optional |

| Rewinding Roll Maximum Weight | 1000Kg |

| Machine Voltage | 380V, 50Hz, 3 Phase |

| Machine Weight | 3500Kg |

| Overall Dimensions | 3600mm*4700mm*2000mm |

| Applicable Materials and Specifications |

| JT-SLT-1300F multi-functional slitter rewinder machine suits to the slitting and rewinding of various ultra-large type coiled material, such as plastic film (PVC, OPP, PET, CPP), paper, glass paper, aluminum foil, adhesive sticker, non-woven fabrics, etc. |

| PLC control system and color interface HMI, all the parameters are shown on the screen. You only need to setup roll diameter, material thickness and original tension etc, the machine could work automatically. |

| Frequency inverter, 3 asynchronous servomotor, one motor for material feeding, the other 2 motor controls the tension. |

| Hydraulic loading system, this part controlled by separate motor. |

| EPC (edge position controller), ultrasonic edge sensor, linear guideway, precision linear actuator), enables accurate slitting precision for printed material. |

| Balance roller for controlling material tension, especially for thin materials. |

| Dynamic / static balancing transmission shafts. |

| Automatic meter counter, When reaches preset length, machine stops automatically. |

| Emergency switch. |

| Machine parts and wall processed by CNC, the wall is much stronger than other supplier’s, it’s thickness up to 45mm. And the painting adopts baking painting. |

| Electrostatic eliminator and razor blades for thin film material (optional). |

JT-SLT-1300F Multi-Functional Slitter Rewinder

Last Update Time:18/10/2023

The JT-SLT-1300F multifunctional slitter rewinder machine is both a cost-effective and functional slitting machine.

It can handle a wide variety of materials, including paper, plastic film, household aluminum foil, non-woven fabric, and adhesive labels, and its price is quite competitive and appealing.

JT-SLT-1300F Slitter Rewinder Machine

During the Print China 2019 exhibition in Apr 2019, we took this JT-SLT-1300F roll to roll the slitting machine to the exhibition site at that time.

Several clients, including those from Eastern Europe and South Asia, sat down with our company’s professional and attractive sales managers to discuss this machine.

Razor blade for slitting thin film

Overall, the JT-SLT-1300F paper roll slitter did show its own style at Print China 2019, you can also feel this in the demo video below, the video was taken during the exhibition period.

If you are now looking for a duplex slitter rewinder, please pay special attention to the following advantages or selling points of JT-SLT-1300F slitting equipment.

Firstly, the JT-SLT-1300F plastic slitting machine is able to convert many types of material.

You could switch between plastic film, kinds of paper, aluminum foil, and adhesive labels if you have JT-SLT-1300F in your hand.

2nd, the JT-SLT-1300F aluminum foil slitter equips with an automatic hydraulic jumbo roll loading rack, its loading capacity is up to 3 tons, and you could load the jumbo roll easily, saving your labor and time consumption.

Separate Motor Driven Hydraulic Jumbo Roll Loading Rack

So as to guide the web material to the slitting part neatly, the JT-SLT-1300F high-speed slitting machine’s EPC (edge position controller) plays an important role.

Once any deviation is detected, the precision linear actuator swings the machine wall panel left or right alongside the linear guideway.

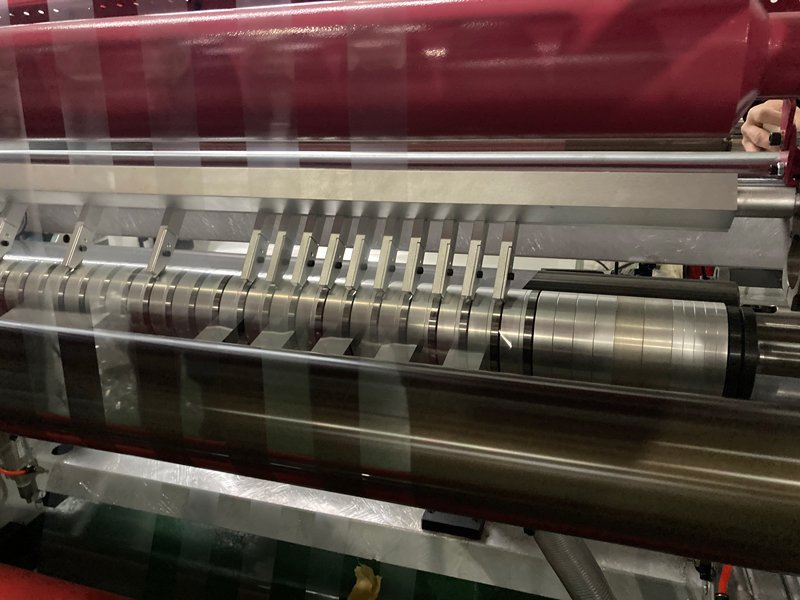

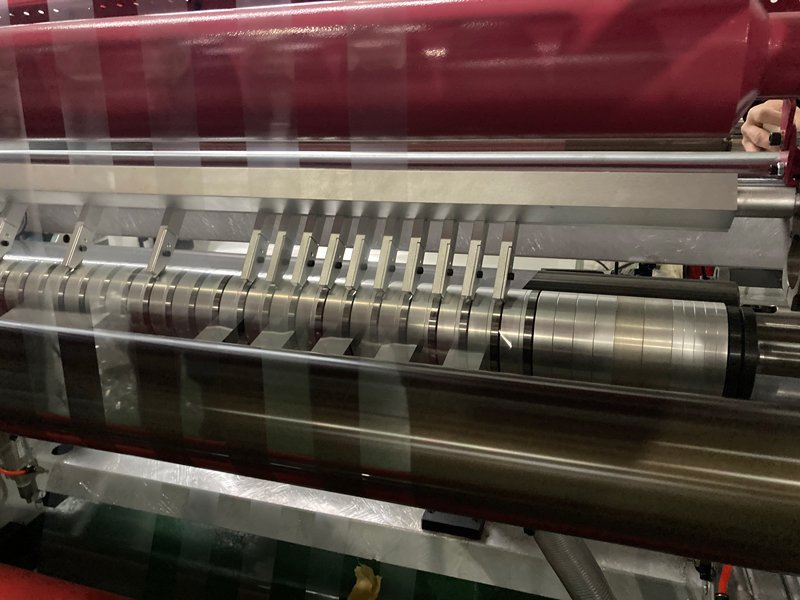

When it comes to the slitting part, circular knives and razor blades are optional for you to cut different materials.

Circular knife shear cutting is mainly introduced to handle paper-related materials, while razor blades score cutting is usually applied for thin plastic film processing.

In order to reduce your labor strength and improve your efficiency, we could supply a fully automatic round disc knife positioning system for slitting width adjustment.

Automatic Knife Positioning System

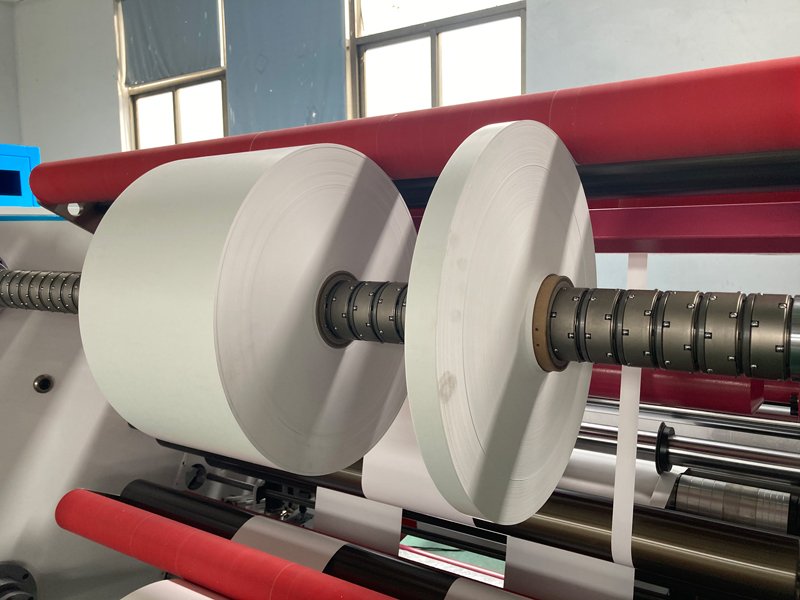

After the material passes through the slitting section, then it reaches the winding part. For the winding part, there are 2 types of rewinding shafts for your choice.

The ordinary type is air expanding shaft, it is suitable for winding materials with even and smooth surfaces in all parts;

The special type is differential friction shaft, such shaft is specially designed for uneven and not smooth surface materials.

As you may use a 1300F paper slitting and rewinding machine to transfer PVC, OPP, PET, and CPP film jumbo roll to small terminal rolls, an electrostatic eliminator could be installed in this set machine to eliminate static electricity.

Static electricity is generated by friction between the material and the air during the web-feeding process.

Only by eliminating static electricity, dust couldn’t contaminate the film, and the future sealing effect of the film will not be affected.

There are many other facts, and features about Jota’s JT-SLT-1300F fabric roll cutter slitting machine, please submit an inquiry to us, we will get back to you with a professional solution.

Multi-Functional Slitter Rewinder FAQ Guide

- What Is a Multi-Functional Slitter Rewinder Machine?

- What Are the Applications of Multi-Function Stretch Slitter Rewinder Machine?

- What Are the Advantages of Using Multifunction Laminating Slitting Machine?

- How Does the Multifunction Slitter Rewinder Machine Work?

- What Are the Winder Procedures, Operations, And Safety of a Slitting Rewinding Machine?

- What Is the Difference Between a Single Drum, Two Drum, And Duplex Winders in Multipurpose Slitter Rewinder?

- How Do I Carry Out Maintenance for My Multi-Functional Slitter Rewinder?

- What Are Some of The Common Parameters of Multi-Functional Slitter Rewinder Machine?

- What Are the Applicable Materials and Specifications of A Multi-Function Laminating Slitting Machine?

- How Can I Optimize the Shear Slitting Process for Multi-Function Stretch Slitter Rewinder Machine?

What Is a Multi-Functional Slitter Rewinder Machine?

A multi-functional slitter rewinder machine is a machine that can be used for several slitting purposes.

Unlike other paper-slitting rewinder machines, this one allows for different product manufacturing.

The machine adopts the center winding method, which is suitable for slitting and rewinding large-diameter coils.

It is easily adjustable to allow for different materials.

Some of the different kinds of materials you can use with this machine include:

- Plastic film

- Paper

- Household aluminum foil

- Non-woven fabric

- Adhesive labels

- Prepregs

- Pressure-sensitive vinyl

Our slitting rewinding machines are of high precision, with high sensitivity.

This means that you will be able to assure your customers of quality products.

The slitting rewinding machines are also fully automatic.

They come with features such as automatic detection, automatic correction, and automatic meter counting.

It Is also equipped with dual-frequency conversion synchronous control, optional shaftless feeding, and automatic feeding.

Photoelectric tracking and an edge correction system are also some of the features that come with this machine.

The automated features ensure accurate slitting, fast speed, convenient operation, and maintenance.

The multi-functional slitter rewinder machine is recommended for its simplicity.

Reach out to us for more information on our multi-purpose slitter rewinder. We also have room for configuring your machine to your own specifications.

What Are the Applications of Multi-Function Stretch Slitter Rewinder Machine?

The multi-functional slitter rewinders can be configured to handle different types of materials. Such materials may include:

- Different types of paper such as kraft paper, coated paper, and special paper.

- Plastic film

- Household aluminum foil

- Non-woven fabric

- Adhesive labels.

The multi-function stretch slitter rewinder machine can convert many types of material.

You could switch between plastic film, kinds of paper, aluminum foil, or adhesive labels.

The heavy-duty slitting rewinding machine is equipped with an automatic hydraulic jumbo roll loading rack.

The loading capacity is up to 3 tons.

You can load jumbo rolls easily, saving your labor and time consumption.

The edge position controller installed on the heavy-duty slitting rewinding machine helps guide the web material to the slitting part neatly.

The multi-functional slitter rewinders can also be used in the transfer of PVC, OPP, PET, CPP film jumbo rolls to small terminal rolls. Other applications of multi-function stretch slitter rewinder machine include;

- Soft material production

- Converting various materials

- Packaging

- Construction paper making

- Tissue paper production

- Paper towel production

- Aluminum foil production

- Water-activated tape production

The multi-functional slitter rewinder machine can also be used for slitting fax paper, money sign-up paper, movies, self-adhesive trademarks, and other paperless than 250GSM.

What Are the Advantages of Using a Multifunction Laminating Slitting Machine?

Some of the advantages of using a multifunction laminating slitting machine include:

Economical and practical

Multi-functional slitter rewinder machine is economical and practical. It can handle many kinds of materials such as paper, plastic film, household aluminum foil, adhesive labels, and non-woven fabric.

Competitive price

Our Multi-functional slitter rewinder machine is also priced competitively. It is made with your business in mind.

This ensures that you break even quickly for your business. This is because of the pocket-friendly purchase price.

It is important to also be proactive in your shipping processes to avoid certain charges.

These charges may include warehousing fees and extra taxes associated with storage. We ensure that we help you avoid extra charges on your multifunction laminating slitting machine.

Technology

We have ensured that we have incorporated the latest technology when it comes to our multifunction slitter rewinder machine.

Be assured of the seamless functionality of your multifunction slitter rewinder machine.

All the components of the multifunction slitter rewinder machine are the latest in the market.

Our multifunction slitter rewinder machines are available both in automatic and manual modules.

This gives you a great flexibility when it comes to choosing the correct multifunction slitting rewinder machine.

Quality Slit paper roll

The round disc cutter is specially fitted with a built-in cutting head for easy sharpening whenever it is required.

Similarly, it integrates a blade lubrication system that allows the cutting of fuses or fusible materials.

Our multifunction laminating slitting machine is equipped with quality round disc cutters.

This ensures that your jumbo paper roll gets a clean, clear cut.

The multifunction laminating slitting machine comes equipped with double round disc cutters for the cutting head.

Quality slitting rewinding machine

Our multifunction laminating slitting machines are the best in the market.

The quality processes at Jota Machinery are continuous.

We ensure that quality is adhered to from the material acquisition stage to the final product.

We also ensure that our paper roll cutting machine meets the industry’s standards.

By adhering to the set standards, we ensure that you get the best machines in the market.

Feel free to call and inquire on the certification requirements.

It is worth noting that different slitting rewinding machines will require different certifications.

How Does the Multifunction Slitter Rewinder Machine Work?

A multifunction slitter rewinder machine is a machine used to cut large rolls of material into narrower rolls.

To understand how a multifunction slitter rewinder machine works, it is important to learn it in sections.

Slitter rewinders perform a type of shearing that cuts large rolls of material into several smaller rolls.

A slitter rewinder unwinds the material, runs it through the machine to be cut, and rewinds the material on one or more shafts to form narrower rolls.

The three main parts of the working of a slitting rewinding machine are the unwind, the slitting section, and the rewind.

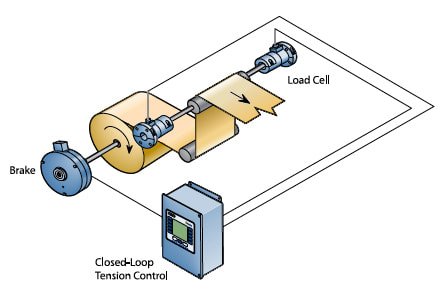

Unwind

The unwind is normally braked to maintain accurate tension in the material.

Some machines have a driven unwind which reduces the effect of inertia.

Inertia is reduced when starting to unwind heavy rolls or when the material is very tension sensitive.

The unwinding stage consists of an unwind stand onto which the parent roll of paper is loaded and secured.

The stand holds the roll about its central axis and allows it to rotate.

The roll is held either by inserting two chucks each with mechanical gripping elements on both ends of the roll which expand to grab it.

It also works by clamping the two exposed ends of a shaft which runs along the whole length of the roll’s core on bearings on the back stand.

When heavy rolls are first unwound, they have a lot of momentum, which can cause the paper to tear or deform materials that are sensitive to pressure.

This doesn’t happen because driven unwinds can be stopped when needed. During the process, the brakes help keep the material at the right tension.

Our paper heavy-duty slitting rewinding machine has clamping mechanisms to hold the jumbo paper roll into place.

We also have slitting rewinding machines equipped with shafts on both ends of the roll.

These shafts clamp the parent roll into place directing it into the slitter section.

Slitting Section

The slitter stage or section of the multi-function stretch slitter rewinder machine is very important.

It largely determines the size, shape, and quality of the paper rolls.

Here, the actual separation of the web into multiple smaller slits occurs. This is achieved by setting the blades to the required specifications.

The slitting stage is where the actual separation of the web into multiple smaller slits occurs.

From the winding stage, the unwound continuous web of paper is passed through a series of spreading rollers and through the slitter head.

The slitter head is made up of a series of rotating round disc cutters or razors and it does the cutting of the web.

The desired slit widths are set manually or automatically depending on the type of machine being used by varying the locations of the knives on the slitter head.

The slitter head is the main component in the slitting section.

This holds the round disc cutters into place. The round disc cutters can be either rotating discs or static.

The type of pneumatic cutters depends on your specifications.

The series of round disk cutters cut the web of paper into desirable sizes.

The cutting method that our multi-function stretch slitter rewinder machine apply is shear cutting.

Here, a bottom-placed round disc cutters work with an upper round disc cutter.

They work in tandem and produce a scissor-like cut. It produces very clean cuts of very high quality.

It is important that you ensure that the round disc cutters are always well set and aligned.

This is to avoid having uneven cuts. Blunt round disc cutters will also lead to uneven edges.

Rewind

Rewind slitting involves rewinding the material through several round disc cutters to form narrower rolls of materials.

The slits are rewound onto smaller cores on the rewind stand to the desired footage or diameter.

This occurs from the slitter head. Various factors determine the type of winder to be used under a given condition.

The rollers which are after the slitter head keep the slit sections separate.

This is as they enter the winding and prevent the sheet from weaving back and forth. This occurs between adjacent rolls in the roll set.

What Are the Winder Procedures, Operations, And Safety of a Slitting Rewinding Machine?

The winder procedures, operations, and safety of a slitting rewinding machine serve as guides.

The guide is on how to operate the slitting rewinding machine.

It is worth noting that different slitting rewinding machines have different procedures on operation and safety.

Most of the slitting rewinding machines in the market are controlled by the machine-man-machine interface.

Prestart Procedure

Before the start of operation of the multi-purpose slitter rewinder, it is important to carry out a pre-startup procedure. The prestart-up procedure includes;

- Checking and making sure that the slitting rewinding machine area is clear of any debris.

- Beware of incomplete installation of equipment and any fasteners or loose parts lying around.

- You should check the shutdown list of your multifunction laminating slitting machine. some of the items to check to include:

- Electrical work required

- Maintenance work is required.

- Any unusual items that may have been shut down or disabled.

- Carry out a 360-degree inspection of your multifunction laminating slitting machine. This is to make sure that the multifunction laminating slitting machine framework is free from tools and equipment not necessary. It is also important in noting any underlying defects.

- The next procedure is to clear all the foreign materials away from your slitting rewinding machine.

- Use the collect instruments, and that all the indicating instruments are in working order.

- Ensure that all the safety guards are in place and that the machine/man interface (MMI) power is ON.

Roll line up

It is also important to check the roll line up for your multi-function stretch slitter rewinder machine.

It is an easy procedure that requires you to indicate the slitting rewinding machine production.

It is a comprehensive checklist on the working of the slitters.

Mechanisms such as the slitter widths, basis weight, set diameter, with of the roll to be cut, and a number of rolls order are some of the items to check in the roll line up.

Specified core size and related information trim average and number of rolls to be cut within the set at the specified width should also be checked. Check to make sure the specified cores (diameter and length) are on hand at the winder.

Unwind Stand

Check to make sure the unwind stand is centered before mounting a new jumbo roll on the slitting rewinding machine unwind stand.

Core Ejection

The cores can be injected both automatically and manually.

New cores must be introduced to the winder using the core feeder.

The cores will automatically be applied with glue during the feeding process.

The reel ejector must be in the return position to take the cores from the feeder and place them, between the winding drums.

Stopping

Always stop the multifunction laminating slitting machine a few inches before the set diameter.

The amount of diameter added to a set after the STOP button is pressed will vary depending on the caliper of the paper.

The speed of the winder will also determine the amount of diameter added to a set.

When the automatic STOP CONTROL selector switch is activated, the winder will automatically shut down when the desired roll diameter is achieved.

Before shutting down the winder system, ALWAYS check to make sure no one is working on the winder.

Also check that all operating devices are in their home positions.

What Is the Difference Between a Single Drum, Two Drum, And Duplex Winders in Multipurpose Slitter Rewinder?

Both the single drum, two drum, and duplex winders are types of slitting machine winders.

Businesses in the paper mill industry often use enormous spools of material in their day-to-day work. But how does an enormous amount of material get onto a spool in the first place?

An answer is a winding machine, which can quickly jumbo paper roll onto an industrial-size spool as needed.

To understand the different types of winders, it is important to be knowledgeable of the multipurpose slitter rewinder features. The features include:

- Web break detection: Multipurpose slitter rewinder include sensors that monitor the material being rewinder. Many of these sensors work by sending a beam of light toward the material and detecting whether the light is reflected.

- Automatic splice initiation: Automatic splicing features are used to create clean cuts with no overlap. In general, automatic splicing features are used to enhance productivity, control quality, and reduce waste.

- Roll changing: Roll-changing features allow users to set maximum diameters for spooling. Once that maximum diameter has been reached, the roll-changing feature swaps out the full spool for a new one.

- Actuated knife cut-off: Actuated knife cut-off triggers a blade to cleanly cut the end of the material once the web has reached its maximum diameter. Quality round disc cutters create clean, precise cuts.

Duplex Slitter rewinders

These type of rewinders are used where certain substrates cannot be wound on a single shaft.

These materials, such as most films, will interweave or create other problems unless the slit cuts are alternated up and down on two rewind shafts.

Often each slit cut is affixed to the rewind shaft through a series of spacers which act as clutches, allowing each roll to wind correctly.

These winders can use score slitting, shear slitting, or razor slitting methods.

Two Drum Slitter Rewinder

Two drum surface slitters are commonly used to slit and rewind paper and board products.

They wind the material by driving the surface of the roll with the drums while pressure is placed on top of the rewinding roll with a so-called “rider roll”.

The material is typically slit either with a score method or a shear method.

They can slit from very narrow widths, about 2 inches, to very wide widths, more than 150 inches.

And they can slit and rewind a broad range of products from tissue to very dense board.

There are many variables involved in choosing the best machine for an application. Feel free to ask for our advice.

Single Drum Slitter Rewinder

Single drum slitter rewinders are used for small rolls of material.

They do not to have to unwind and rewind the substrate.

The jumbo paper roll is placed on a mandrel matching the inside core diameter.

The jumbo paper roll is then rotated while a rotating round disc cutter is inserted into the jumbo paper roll at the appropriate widths.

Other types of slitters rewinders include:

- Simplex slitters: A Simplex Center Slitter/Rewinder winds a roll on a single shaft in a similar way to a Two Drum Winder. Unlike the two drums, however, the Simplex rewind shaft grabs the core or cores usually by inflating the rewind shaft with air. The air causes an internal bladder to expand thereby pressing buttons or the leaves of the shaft itself inside the core.

- Continuous winders; Continuous slitters are commonly used for making small diameter logs of material such as gift wrap paper. They are typically fully automatic machines which take a master roll and turn out large quantities of finished rolls requiring only master roll changes.

- Duplex turret winders: They are ideal for high-speed automated winding of small diameter rolls

- Traverse winders: Traverse winders have slitting capabilities to convert a single wide web to several smaller ones. After being slit, the narrower webs are distributed across the width of the cores, or “spools”, onto which they are being rewound. This yields a high density of material in a finished roll that maintains a reasonable diameter.

It is also worth understanding the different types of slitting lines of slitting rewinding machines. There are two basic types of slitting lines:

- On pull-through slitting lines, the recoiler provides the power to pull the coil material off the uncoiled reel. This done through the slitter and recoil of the processed strips.

- In loop-slitting lines, a pit is incorporated into the line. The processed coil strips are looped into the pit which assists in absorbing the strip length differential within the slit coils. The slitter typically provides the power to both uncoil and slit the material, while the recoiler provides the power to rewind the material.

How Do I Carry Out Maintenance for My Multi-Functional Slitter Rewinder?

Multi-functional slitter rewinder requires regular maintenance. For your multi-functional slitter rewinder to last longer, you should do regular maintenance.

All our multi-functional slitter rewinder come with a guide on how to go about the maintenance procedure.

Before you embark on maintenance, you should put the following in mind:

- Ensure that you are qualified or qualified personnel undertakes the maintenance procedure.

- Ensure that the area you want to undertake the maintenance is clean ad free from debris.

- Check that all the electrical components are in their terminals.

- Switch of the power and put a safety lock before maintenance.

- Use appropriate safety signs when doing maintenance.

- Ensure that you wear the right personal protective equipment while carrying out maintenance.

- For larger multi-functional slitter rewinder, ensure that you have someone to assist you in the maintenance.

After following the safety procedures, you can begin the maintenance protocols of your multi-functional slitter rewinder.

Different multi-functional slitter rewinder require different maintenance procedures. Some of the common steps of carrying out maintenance include:

- First, you should switch off the paper multi-functional slitter rewinder. Put a safety lock on the power source. This will ensure that no one can switch on the machine when it is under maintenance.

- Inspect all the parts of the multi-functional slitter rewinder. Look for any loose or broken parts. For the moving parts such as the rollers and the round disc cutters, check the levels of lubrications.

- Check off all the issues following the Jota Machinery paper slitting machines maintenance manual.

- Clean the rollers and all the parts that can be dusted. Use the recommended cleaning agents and avoid bleach.

- Clean out all the bright surfaces. Coat the surface with rustproof oil for durability. If the heavy-duty slitting rewinding machine has not been in use for sometimes, use anti-rust oil.

- Oil all the moving parts. Use recommended oil and check its quality. Using substandard oil will lead to wear and tear of the moving parts.

- Check the wiring of all the electrical parts. Check that no cables are loose or out of their terminals. Replace any worn-out cables and note down the diagnostics. One in a while, you can use a blower to remove dust particles on the wiring. Never use a wet cloth on the electrical wirings of the heavy-duty slitting rewinding machine.

- Check the round disc cutters. Check out for wear and tear and replace them accordingly. Be sure to wear protective gloves to avoid cuts from the round disc cutters. Some round disc cutters need sharpening regularly. Ensure you sharpen them following our provided maintenance manual.

- Follow the maintenance schedule. Do not carry out unauthorized maintenance on your slitting rewinding machine.

- Any component that needs adjustments or replacement should be flagged off early. If you are not sure of how to go about the replacement, kindly contact us.

- Record all the major maintenance undertakings such as parts replacements, electrical parts issues. This will enable subsequent slitter machine maintenance protocols. It is also helpful in understanding the root cause of an issue.

- The personnel and operator of the multifunction laminating slitting machine should undertake regular training. This is important in keeping up with the latest multifunction laminating slitting machine technology.

What Are Some of The Common Parameters of Multi-Functional Slitter Rewinder Machine?

Our multi-functional slitter rewinder machine is manufactured to meet your paper mill business capabilities.

It is made to ensure that you deliver your customer’s orders in good time.

Some of the common parameters of the multi-functional slitter rewinder machine include:

- The multi-functional slitter rewinder machine has a maximum unwinding width of 1300mm.

- It also has a maximum unwinding diameter of 800mm.

- Our multi-purpose slitter rewinder is equipped with a maximum rewinding diameter of 800mm.

- The slit width of the multi-functional slitter rewinder machine ranges from 30mm to 1300mm.

- The unwinding and rewinding shafts have a 3’’ (76mm) air expanding shaft.

- To ensure maximum productivity, the rate power of ourmulti-functional slitter rewinder machine is 18Kw.

- The wall thickness is 50mm ensuring that your multi-purpose slitter rewinder serves its purpose.

- The rewinding shafts have a differential friction shaft. This provision is optional. Contact our sales agents or liase with in case that you prefer customized rewinding shaft.

- The rewinding roll of our multi-function stretch slitter machine has a maximum weight of 1000Kg.

- The machine voltage is 380V, 50Hz, and 3 phases, respectively.

- The multi-functional slitter rewinder machine weighs 3500Kg.

- The overall dimensions of the multifunctional slitter rewinder machine is 3600mm*4700mm*2000mm.

What Are the Applicable Materials and Specifications of A Multi-Function Laminating Slitting Machine?

Our multi-function laminating slitting machine are particularly designed to the highest quality.

All the specifications as outlined are in tandem with the functions of the multi-function laminating slitting machine.

Multi-functional slitter rewinder machine suits to the slitting and rewinding of various ultra-large type coiled material.

These materials include plastic film (PVC, OPP, PET, CPP), paper, glass paper, aluminum foil, adhesive sticker, and non-woven fabrics.

The applicable materials and specifications of a multi-function laminating slitting machine include but not limited to:

- Our applicable materials and specifications of a multi-function laminating slitting machine are equipped with PLC control system and color interface HMI. All the parameters are shown on the screen. You only need to setup roll diameter, material thickness and original tension. After setting up the parameters, the multi-function laminating slitting machine works automatically.

- The multi-function laminating slitting machine also has a frequency inverter installed. It also has a 3 asynchronous servomotor. The motors work in enhancing the tension of the web. One motor for material feeding, the other 2 motor controls the tension.

- Multi-function slitter rewinder machines also have a hydraulic loading system. The hydraulic loading system is controlled by a separate motor.

- Our multi-function laminating slitting machines are enabled for accurate slitting precision for printed material. They are equipped with an edge position controller (EPC), ultra-edge sensor and linear guideway. They are also equipped with a precision linear actuator; all these components work towards ensuring accurate slitting precision for printed material.

- A balance roller for controlling material tension also comes installed. This is ideal for thin materials.

- A dynamic or static balancing transmission shafts are also installed on the accurate slitting precision for printed material. This serves to ensure that the final slitted paper rolls are of good quality and achieve clean cuts.

- Our slitting rewinding machine has an automatic meter counter. When the automatic meter counter reaches a preset length, it stops automatically.

- The multi-function stretch slitter rewinder machine is also equipped with an emergency switch. This is particularly important especially when you have material clogging or issues with the slitting rewinding machine.

- The multifunction laminating slitting machine parts and walls are processed by CNC. We guarantee you of a strong wall compared to what is offered by other manufacturers. The CNC processed wall has a thickness of up to 45mm. The painting for the multifunction laminating slitting machine adopts baking painting.

- The multifunction laminating slitting machine is also equipped with an Electrostatic eliminator. You can also customize it with razor blades for thin-film material.

At Jota machinery, we allow for the customization of your multifunction laminating slitting machine. you can liaise with us to talk to our design engineers about the specific designs you would want to be incorporated.

How Can I Optimize the Shear Slitting Process for Multi-Function Stretch Slitter Rewinder Machine?

The slitting process is an important part in any multi-function stretch slitter rewinder machine.

This makes it important to optimize the process to reduce wastages from wrong slitting methods.

Shear slitting is the most versatile and commonly used method to slit flexible web materials.

It is also demanding while requiring close attention to achieve high-quality slitting.

You must ensure that certain variables are controlled to ensure optimization of the slitting process. These variables include;

Round Disc Cutter Sharpness

The multi-function stretch slitter rewinder machine uses a rotary shear process.

The rotary shear process works by slitting materials in the nip between two overlapping round disc cutters.

The hardened round disc cutters create stress in the shear mode sufficient to tear off the web of paper roll.

Razor slitting on the other hand has compressive stress when crush/ score slitting.

The different characteristics of the round disc cutters such as sharpness should not be confused with the grind angle.

The grind angle is also called the cross-sectional profile of the slitting round disc cutters.

It is important to ensure that all the disc cutters for your multi-function stretch slitter rewinder machine have sharp edges.

The profile of the round disc cutters can vary widely and still meet the criteria for sharp blades.

Cant Angle

The cant angle is also known as the shear angle. The cant angle assures a closed nip.

Like a pair of scissors, the round disc cutters must be in contact at the nip or cut point to give clean cuts.

The shear angle largely depends on the quality of the material being used on the multi-function stretch slitter rewinder machine.

Certain materials are very sensitive to cant angle settings. Other materials seem to slit well giving clean quality shear cuts.

Elasticity, elongation, and fiber orientation are important factors that you should consider when choosing the optimum cant angle.

Ensure that when you have a low elongation, the cant angle is also low. A high elongation also equals to a high cant angle.

Overlapping

When you increase the tangent point of your multi-function stretch slitter rewinder machine, the upper and lower blades shift the cut point ahead of the tangent point.

This is not recommendable because the blade will tear your web.

The upper round disc cutter strikes the web too soon severing it if it does not get the support of the lower round disc cutters.

Unlike the tangent systems, in wrap systems, the cut point has little effect on slit quality.

Increasing the overlap in both the wrap and tangent systems increases the deflection of the web.

The amount of deflection the web must take to go around the upper blade can decrease the slit edge quality.

Side Force

The sliding force of the multi-function stretch slitter rewinder machine means the amount of force applied from the upper round disc cutter to the lower round disc cutter.

The side force creates friction between the upper round disc cutter and the lower round disc cutter.

This creates a rotational speed of the upper disc cutter creating the nip speed at the cutting point.

Note that a high side force results to the blade wear-causing deflection in the upper disc cutter.

A deflection on the upper disc cutter results in the opening of the nip point.

To mitigate this, the side force should be as light as possible. This is important in maintaining a closed nip and appropriate nip speed.

Nip Velocity vs Web Velocity

In shear slitting, the nip velocity must equal or ideally be faster than the web velocity.

If the nip closes at a speed slower than the web, slit quality reduces.

This leads to dusty, ragged, and distorted paper roll edges.

Any distortion of the web immediately in front of the top slitter is a sign that the slitters are running slower than the web speed.

When using a multi-function stretch slitter rewinder machine with tangent systems, the remedy is increasing the Overspeed to compensate for the speed loss.

On a multi-function stretch slitter rewinder machine with wrap systems, Overspeed is not easily resolved.

This is because you cannot realistically Overspeed enough to compensate for speed differential.

Slitter Geometry

Shear slitting systems can be configured to either tangent or wrap.

Most of the primary winders are configured to tangent slitting.

On the other hand, most of the secondary winders are configured for wrap slitting.

Trim Removal.

As edge trim is removed from the web, the tension across the web is altered.

When the trim material is redirected away from the web path, it leads to the reduction of the slit edge quality.

To promote good edge quality, the supported slit should be on the web site of the edge trim.

The edge trim material should follow the path of the web at the same speed as it leaves the nip point.

In order to let you know more about we Jota company, please watch the following video for reference.

We Jota could also supply following related machines, if you are also interested in any type, please feel free to send us an inquiry:

- Hot Melt Thermoplastic CFRP CFRTP Prepreg Manufacturing Machine

- Fully Automatic Thermal Paper Roll Slitting Packing Machine

- Fully Automatic Toilet Paper Maker

- Automatic Facial Tissue Making Machine

- Paper Sheeter

- Paper Tube Making Machine

- CFRP CFRTP FRP Prepreg Slitter

- Paper Drinking Straws Machine

- Label Die Cutting Machine

- Flexo Printing Machine

- Cardboard Tube Cutting Machine