Paper Slitter Rewinder Machine Manfacturer in China

- Not Only Works For Flexible Packaging Material But Also Fiber-Reinforced Thermoplastic Composites.

- Method: Slitting , Die-cutting,Kiss-Cutting

- Paper Mill and Personal User

- From Economic Type to Fully Automatic Type

- Round / Pneumatic / Shear Slitter Blade

- Original Machinery Manufacturer

Slitter Rewinder Machine

If you are looking for a suitable jumbo roll slitting rewinding machine whether you are in the field of printing, packaging, new energy, aerospace, or new carbon fiber technology materials.

Our professional team could meet your requirement to providing a suitable solution on slitting rewinding machine.

As a professional jumbo roll slitting rewinding machine manufacturer, we have not only 20 years of experience, but also a highly educated R&D team, advanced mechanical design team, and electrical software design team.

These can ensure that our slitting rewinding machine can meet customer needs and conform to the market requirement.

At the same time, our company is also completing its own upgrading and transformation.

From the most basic paper and film roll slitting rewinding machine to the latest new energy carbon fiber and the slitting of aerospace materials, this is also a testimony of our own strength.

Currently, we can provide slitting machines for various materials.

The width of parent mother rolls can reach from 50mm to 3500mm, and the slitting width can range from 3mm to 3500mm.

There are various winding methods such as reverse winding, disc winding, and rewinding. The maximum diameter can be up to 1800mm. There are also various slitting models for you to choose from.

Many people have a misunderstanding about the slitting rewinding machine.

You think that it is to find a simple machine to cut large rolls into small rolls or rewind them into small rolls.

In fact, different material characteristics, hardness, tension requirements, and subsequent processes are different.

The requirements vary greatly.

For each different material, the material threading flowing route on the machine, the angle between the roller and the diameter of the roller, and the selection of the slitting knife are all professional technical issues.

If you are looking for a professional jumbo roll slitting rewinding machine supplier, Jota Machinery should be your best choice.

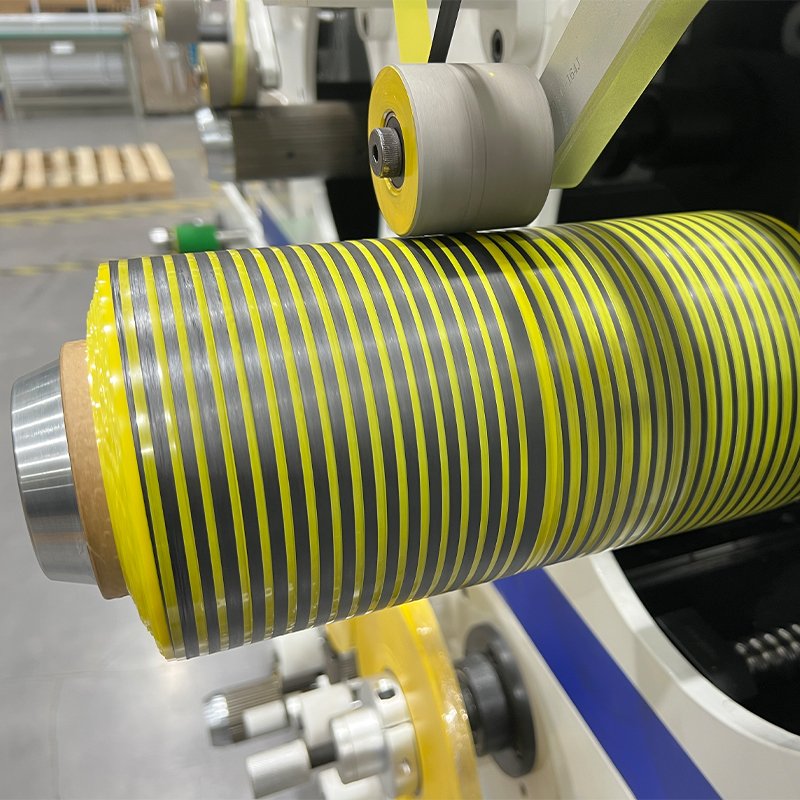

Jota slitting rewinding machine could be applied for many different materials,

such as adhesive labels, kinds of paper, film, foil, non-woven fabric, CFRP, CFRTP, FRP prepreg, etc.

For a deep discussion about Jota slitting rewinding machine, please just send us an inquiry.

CFRP, CFRTP, FRP Prepreg UD Tape Slitting Rewinding Core Technology

Jota Machinery: Original Slitting Rewinding Machine Manufacturer in China

Jota is capable of manufacturing 30 sets of slitting rewinding machines in 1 month.

We also accept free material converting test, you just need to send some of your material to us.

we will use our Jota slitting rewinding machine test it, then show you the testing video.

Machining Material

- Visible high-quality components.

- Famous brands such as Siemens, Yaskawa, Delta, Schneider, Mitsubishi.

- Self-supporting CNC processed sheet metal, precision parts.

- Assembly raw materials provided by long-term cooperation suppliers.

Installation and operation user manual, wire connection diagram, tension controller guide.

Installation and operation video tutorial.

One-on-one remote video call assistance.

On-site installation and operation guidance.

- Focus Factory

- Dear Customer

- Professional Team

Around 30-45 days, mainly depends on machine type.

Sure, it is our honor to work for you.

We will offer you some parts as backup, in case any part is broken within one year, we will sent you for free.

Sure, if we have client in your country, we will offer.

Mastering Material Conversion: The Slitter Rewinder Machine Guide

A slitter rewinder machine sometimes called a paper roll slitting machine .

The slitter is the essential tool responsible for the intricate process of converting large jumbo rolls into smaller ones.

Its primary function is straightforward: it precisely slit various materials like paper, thin plastic film or thick PE coated cupstock paper jumbo rolls to create narrower rolls.

To grasp this concept in everyday scenarios, think about your interactions with an ATM or your use of toilet rolls.

Those ATM receipts you receive were once part of colossal thermal paper jumbo rolls.

However, thanks to the precision of the slitting process, these rolls are transformed into numerous smaller rolls, ready to serve their crucial role in providing transaction receipts.

This technology not only streamlines industries but also enhances our daily convenience and efficiency.

A slitting machine comprises three essential components:

- The unwinding stand

- The slitting unit

- The rewinding unit

The process begins with a mother roll of the selected material, which is fed into the slitter’s unwind section.

The raw material unspools and undergoes precise slitting, resulting in various widths.

Subsequently, the newly cut material is rewind into cores of different widths, making it a versatile and efficient tool for customizing material dimensions to meet specific requirements.

The slitter rewinder machine is ingeniously designed to efficiently transform an original roll into multiple strips and then meticulously rewind them onto a fresh roll.

This ingenious process plays a vital role in curbing manufacturing costs by minimizing waste material, which might otherwise be expired if not processed within the validity period.

One of the standout features of these machines is the dynamic round slitting blade.

Cutting blade is adaptable to a wide range of material cutting needs, ensuring precise and efficient operations.

In the realm of paper converting, various slitting blades like round slitting blade, pneumatic slitting blade, shearing slitting blade, and razor slitting are utilized for cutting different materials.

Metaphorically speaking, you can envision a slitter rewinder as a well-structured company.

The rewinding unit acts as the quality control center, ensuring the final product meets the highest wind standards.

The unwinding unit serves as the production department, providing the raw material for the process.

The slitting unit functions much like the sales department, catering to specific customer requirements.

In essence, the combination of these three core units creates a complete and highly efficient slitter rewinder machine, indispensable in various industries for precision material processing.

Are you on the hunt for the perfect slitter rewinder to streamline the slitting and rewinding of your materials?

Slitter rewinder machines are the linchpin in transforming large rolls into precisely sized products that meet market demands.

Choosing the paper roll slitting machine can have a profound impact on the efficiency of your production process.

The next couple of suggestions offer you a wealth of information to empower you with the knowledge needed to make a well-informed decision when it comes to selecting a slitter rewinder.

Continue reading to uncover the critical factors to consider and the essential details to convey to Jota Machinery when seeking a quote.

Prior to embarking on the journey of selecting the ideal slitter rewinder, it’s imperative to gain a comprehensive understanding of the materials you’ll be working with.

Different slitter rewinders are purpose-built for handling specific materials, including paper, film, or foil.

Key considerations include material thickness, maximum width, and maximum roll diameter.

This knowledge is pivotal in ensuring that the slitter rewinder you ultimately choose is a seamless fit for your material specifications.

In your quest for the perfect slitter rewinder machine, precision is paramount when it comes to identifying your required specifications.

It’s essential to nail down details such as the desired width and length of the finished rolls, the number of cuts needed, and the preferred machine speed.

These specifications are not mere details; they are the linchpin for determining the most fitting type of slitter rewinder that will seamlessly align with your production requirements and ensure efficiency and effectiveness.

Picking the right manufacturer is a pivotal step when you’re in the market for a slitter rewinder.

It’s essential to opt for manufacturers with a solid reputation, a wealth of industry experience, and satisfied customers who can vouch for their products.

Furthermore, don’t forget to explore their after-sales support and warranty policies.

This ensures that you’ll have the necessary assistance and service throughout the lifespan of your equipment, providing peace of mind and reliability in your investment.

One of the most critical steps in your slitter rewinder journey is to provide accurate and comprehensive information to the manufacturer.

When you reach out to a manufacturer, be sure to give them all the essential details about your materials, specifications, and production requirements.

This level of transparency empowers the manufacturer to make the best possible recommendations, ensuring that the slitter rewinder they offer aligns perfectly with your unique needs.

Additionally, remember to inquire about any customization options that may be available, as tailoring the machine to your specific requirements can be a game-changer.

Ultimately, choosing the right slitter rewinder is the key to optimizing your material processing and meeting your production demands.

With a solid understanding of your material, precise specifications, equipment capacity considerations, and the selection of a trustworthy manufacturer, you can make an informed decision that leads to seamless operations, cost savings, and maximum efficiency for your business.

Jota Machinery stands as a professional slitter rewinder manufacturer, boasting over a decade of converting experience in thermal paper and flexible packaging materials.

Our journey has been one of growth and diversification, expanding our offerings to include not only slitting process machines but also sheeter machines , flexographic printing machines even expanding to composites thermplastic UD prepreg machine .

We take pride in delivering a comprehensive suite of solutions to meet your specific needs.

To ensure we recommend the most suitable converting machinery for your requirements, we encourage you to share as much information as possible with our professional sales team.

The more insight you provide, the better equipped we are to tailor our solutions to your precise needs, guaranteeing your satisfaction and success.