Leading Thermal Paper Slitter Rewinder Machine Manufacturer

- Various type thermal paper slitting machine available

- Adopt famous brand spare parts

- Choice of Portugal famous brand Navigator

- Customer service footprint across the world

Thermal Paper Slitter Rewinder Machine

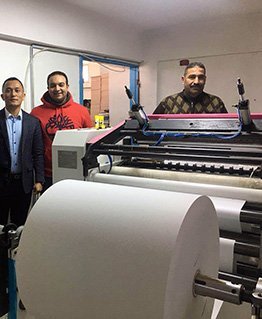

Thermal Cash Register Paper Slitter Rewinder is always Jota’s core product from the very beginning.

Jota thermal paper slitting machine’s iconic clients include Navigator, SS Labels, K.M.S Group, etc.

When you are shopping in the supermarket or having dinner at a restaurant and swiping your credit card, there is a small cash roll of paper, which is very popular nowadays. It is thermal reception paper or thermal cash register receipt paper. There is a great demand for this kind of paper in the current market, and it penetrates all aspects of your life. Therefore, the thermal paper slitting converting should be a good business for you, it is with a small investment and quick return.

As a professional thermal paper slitter rewinder machine supplier, after 20 years of industry precipitation, we could now provide a full set of thermal paper cashier receipt solutions chain from A to Z, from base thermal paper mother roll, paper core (plastic core), thermal paper slitter rewinder Machine, thermal paper printing machine, cash roll finishing wrapping line, and packaging film, we could provide a full set of professional solutions.

Submit your requirements now, we will recommend a suitable thermal roll slitting machine to you.

Jota Machinery: Your Trustworthy Thermal Paper Slitting Rewinding Supplier in China

Jota is a reliable thermal paper slitter rewinder supplier, we have our own factory and CNC center.

We are able to offer a one-stop solution for your thermal paper roll business.

To OEM your desired thermal paper roll machine, please submit your request to get a quote.

Machining Material

- Visible high-quality components

- Famous brands such as Siemens, Yaskawa, Delta, Schneider, Mitsubishi

- Self-supporting CNC processed sheet metal, precision parts

- Assembly raw materials provided by long-term cooperation suppliers

Installation and operation user manual, wire connection diagram, tension controller guide.

Installation and operation video tutorial.

One-on-one remote video call assistance.

On-site installation and operation guidance.

- Factory

- Customer

- Specs

| Max. Unwinding Width | 1400mm |

| Max. Unwinding Diameter | 1000mm |

| Max. Rewinding Diameter | 300mm |

| Min. Slitting Width | 25mm |

| Max. Machine Speed | 300m/min |

Around 30-45 days, mainly depends on machine type.

Sure, it is our honor to work for you.

We will offer you some parts as backup, in case any part is broken within one year, we will sent you for free.

Sure, if we have client in your country, we will offer.

Differences Between Fully Automatic Thermal Paper Slitting Machine And Semi-Automatic One

Last Update Time:27/03/2022

Many buyers have asked the same question: What is the differences between our Fully Automatic Thermal Paper slitting machine and a Semi-automatic one

In order to help you understand the details of the machine and choose the best line, we will explain these differences in detail in the next section.

If you are very experienced in this industry, you must know that these two lines are both composed of four parts: automatic core loader, paper slitting rewinding machine, conveyor, and packing machine.

Firstly, I would like you to have a visual comparison in labor. If you just have the thermal paper slitting machine in your factory, then you need at least 4-6 operators.

One person is used to load and unload the core, and one or two people are used to flatten the thermal rolls. Two or three people for the packing operations.

But if you have a semi-automatic production line, all you need is one person to finish the working process.

And if you want to expand the production scale or reduce the labor cost, then a fully automatic thermal paper slitting machine will be your best choice.

So, it seems obvious that a fully automatic thermal paper slitter can save a lot of time and money on labor costs. That’s why our machines that do everything for you sell well in Europe.

Aside from that, I want you to know that the semi-automatic paper slitting machine can make 13,440 small rolls per day (8 hours).

A fully automatic thermal paper slitter can produce almost 3 times the output of a semi-automatic line. Then you can calculate this amazing yield.

In terms of price, our fully automatic line is very advantageous in the global market.

because we develop our own research and development production, so our machines are the best quality in the same price range.

At the same time, you will find that our machines have European advanced technology, and the price is only half of theirs.

Next, let’s talk about how to load the core. The semi-automatic line uses a rewinding shaft, you have to put the paper core or plastic core manually into the rewinding shaft.

One person has to use the rewinding shaft over and over again to load and unload the core.

But, The fully automatic line has a core hopper that works by itself and a rewinding process without the rewinding shafts. The core would be sucked into the rewinding devices automatically.

After that, the vacuum core sucker will suck up the core and move it forward to the rewinding station through the suction nozzle. The position and quantity of the core suction nozzle can be selected according to the width of your thermal paper mother roll.

When the core sucker moves forward, the front crossbar pushes the last cycle till rolls to the finished roll processing station, and these sucked cores are also placed on the rewinding station at the same time.

After placing the cores, the vacuum core sucker moves backward to the initial position, and a layon roller presses down on the finished till roll.

So you can know that the fully automatic line greatly improves production efficiency while saving labor costs.

The second biggest difference is the unwinding section. The semi-auto line adopts a chain lift-up loading system and automatic tension control system to keep constant tension.

3’’ air expanding shaft and magnetic brake for tension control, the Max. unwinding diameter is 1000mm

As for the fully automatic line, the unwinding stand adopts a hydraulic shaftless unwinding system and it is an independent unwinding stand.

With max. loading weight of 3000kgs, which could be controlled by remote control for the operation, it greatly saves the operator’s physical strength.

In addition, It adopts 2 sets of sensors and a fully automatic tension controller.

We also equip the fully automatic line with photocell and deviation correction systems for the whole line inspections to ensure all the consequences of the operations.

The third difference that must be mentioned is the rewinding section. The rewinding section of the semi-auto line is relatively simple, the max rewinding diameter is 160mm and the rewinding shaft is 0.5’’ or 1’’ or as your requested.

As for the fully automatic thermal paper slitting machine, the rewinding part adopts surface rewinding technology. The vertical 90-degree lay-on roller and the banana roller’s combination can effectively avoid the overlapping problem.

In the rewinding part, the Jota Machinery assembler installs an automatic tucker for the fully automatic line. The automatic tucker can quickly tuck the tail, then triggers the rewinding.

With the addition of a high sensitive air valve regulator, it is easy to adjust the rewinding tightness freely.

So on our machines, the rewound thermal rolls could be tight or loose freely.

Overall, the rewinding process of fully automatic lines is faster and neater. Therefore, this model is highly recognized by the major brands of thermal paper manufacturing processing.

Finally, let’s come to the slitting cutter assembly. For the semi-automatic thermal paper slitting machine, you need to manually adjust the blades to set different slitting widths, the regular width is 56mm and 79mm.

But for a fully-auto line, we also supply a fully automatic knife positioning system. All the slitting widths could be automatic setup on the touch screen. This greatly saves time and increases productivity.

In addition, this fully automatic production line can meet the production of products of different sizes.

In the slitting round disc knife assembly, shear cutting is used on the upper and lower round knives. Shear round disc cutting can make sure that the slitting is as accurate as possible, avoid problems like burrs, and not change the way the finished till rolls look.

Conclusions:

If your budget is limited or your production requirements are not high, perhaps our semi-automatic line will be a better choice for you.

However, If you prefer high-quality production and higher output, then Jota’s fully automatic production line is definitely the choice you will not regret.

Our advantages are:

- We have our own R&D team and insist on constantly updating the machine to make it more intelligent and easy to operate. By the way, we are the only company that can customize the width of the fully automatic slitter to 1400mm.

- We have our own factory and production department, not just a trading company, and we have 20 years of industry experience. This makes our machines very cost-effective.

- We are close to Shanghai Port and can provide you with a series of services from shipping to after-sales.

Hope the above information are helpful for you, if you have any questions, please send us an inquiry or make a phonecall to us.