JT-SLT-900A Thermal Paper Slitting Rewinding Machine

- Medium price with higher rewinding quality

- Portugal famous brand Navigator’s choice

- Optional hydraulic jumbo roll loading

- Spreader/banana roller

- JT-SLT-900A high-speed thermal paper roll slitting machine

- Video of JT-SLT-900A high-speed thermal paper roll slitting machine

Parameters

| Item | JT-SLT-900A high-speed thermal paper roll slitting machine |

| Max. Unwinding Width | 900mm |

| Max. Unwinding Diameter | 1000mm |

| Max. Rewinding Diameter | 300mm |

| Min. Slitting Width | 25mm |

| Max. Machine Speed | 210mm/min |

| Main Power | 3.5Kw |

| Unwinding Shaft | 3″ air expanding shaft |

| Rewinding Shaft | 0.5″, 1″ or as your request |

| Weight | 2500Kg |

| Overall Dimension | 2050mm x 1700mm x 1500mm |

Specification

| Application |

| JT-SLT-900A high-speed thermal paper roll slitting machine is able to make cash register paper roll, ATM roll, adding machine roll, POS roll, and so on. |

| Unwinding Section |

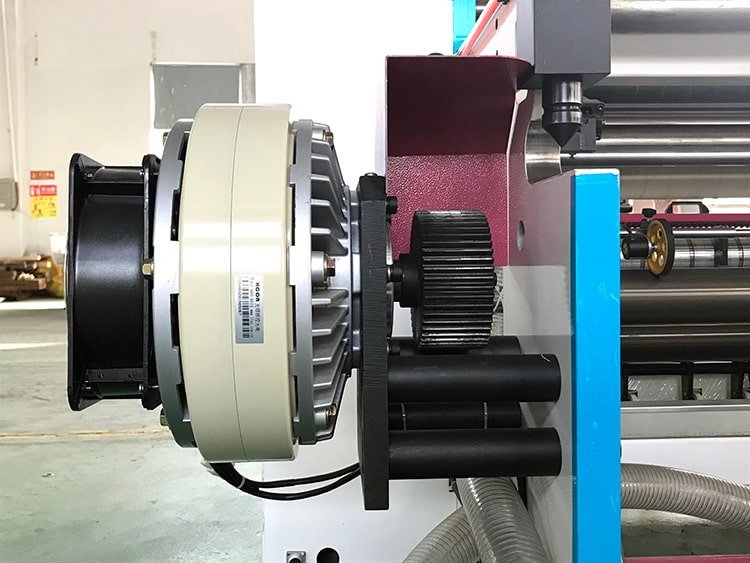

| Pneumatic control automatic jumbo roll loading. With banana/spreader roller, the overlapping problem is avoidable, till roll edge is smooth. Electromagnetic brake from Taiwan. Ultrasound EPC (edge position controller) from Taiwan, high slitting precision. Fully automatic tension controller. |

| Slitting Section |

| Disc blades are fixed by screw, easy adjustment. Adjustable and removable lower blade shaft. Automatic meter counting, after reaching the preset length, the machine automatically stops. |

| Rewinding Section |

| 0.5″, 1″ rewinding shaft or as your request. Surface winding. Auto tucker. |

| Controlling Section |

| Siemens PLC and graphic touch screen HMI. All the parameters are displayed on the screen. Schneider low voltage electrical appliances. EPC for web guiding. |

| Waste Disposal |

| The air blower blows waste material off, the air blower power is 1.5Kw. Stainless steel air blower pipe is more wear-resisting. |

Configurations

Name | Model | Pieces | Remark |

Computer System | PLC (Siemens) | 1 Set | Siemens |

Motor | 1 Set | Siemens from Germany | |

Frequency Inverter | 1 Set | YASKAWA From Japan | |

Unwinding Shaft | 3″ air expanding shaft | Pneumatic Loading | |

Rewinding Shaft | 0.5″, 1″ or as your request | ||

Upper/Lower Round Knife | 15 Sets | ||

Electromagnetic Brake | 1 Set | From Taiwan | |

Tension Sensor | 2 Sets | ||

Tension Controller | 1 Set | Fully Automatic | |

Chuck | Self-expandable chuck | 1 Set | From Taiwan |

Magnetic Clutch | 2 Sets | From Taiwan | |

Low Voltage Electrical Switch | SCHNEIDER | ||

Blower | 1 Set | China | |

Cylinder | Airtac from Taiwan | ||

Precision Regulator | SMC from Japan | ||

Relay | Omron | ||

Spacer | As your request | As your request | China |

EPC | 1 Set | From Taiwan |

JT-SLT-900A High-Speed Thermal Paper Roll Slitting Machine

Last Update Time:27/03/2022

Now, you’re probably wondering what a cash register machine is? Is it the same as the receipts printer? Do I really need a cash register machine? And is the JT-SLT-900A high-speed thermal paper roll slitting machine the same as the thermal paper rolls slitting machine?

Well, these are all genuine questions, and it’s best to get their answers. But for a recap, a thermal paper rolls slitter rewinder machine is something every receipts wholesale business probably needs. As a supplier, you need different receipts sizes. And the slitter machine is what you need to do the job.

You don’t have to keep making orders for different receipt sizes – cut the middleman. Simply get a cash register slitter rewinder and get to work and supply your clients with the exact receipts sizes they need. No more delays on orders clients request simply because you don’t have the sizes they want.

Let the cash register paper roll slitting machine do the work. And that’s where Jota’s JT-SLT-900A high-speed thermal paper roll slitting machine comes in. At Jota Machinery, we offer the most effective slitter rewinder machines to serve your interests best. We have the finest, most qualified, and yet creative engineers whose goal is to come up with the best slitter machines for your receipts supply business.

But that’s not all; let’s have a look at some of the frequently asked questions on the JT-SLT-900A high-speed thermal paper roll slitting machine. This helps understand the slitter rewinder much better.

Some of the freshmen don’t know how to do or how to solve the issue when operating our slitting machine then we made a page for frequent troubleshooting and solution. Kindly check this page

How Different Is the 900A Slitter from 900C and 900mm?

The main difference between the three slitter machines is the maximum speed. And a few advanced features. The 900m offers a max speed of 160m/min, while the 900A has a max speed of 210m/min. The 900C has the highest speed of 300m/min.

JT-SLT-900A high-speed thermal paper roll slitting machine

This means you get to pick either of the slitters based on your production load. All three come in handy when you’re looking to increase your products of cash register receipts.

Apart from their differences in speed, the 900A comes with improved features. For example, the JT-SLT-900A high-speed thermal paper roll slitting machine boasts of ultrasound EPC (edge positioning control), electromagnetic brakes, automatic tension controller, and pneumatic roll loading. These features ensure the JT-SLT-900A high-speed thermal paper roll slitting machine is very effective, thus improving productivity. Which eventually increases profits.

What Features Does the JT-SLT 900A Have?

The JT-SLT-900A high-speed thermal paper roll slitting machine was designed and manufactured with the latest technologies in mind. It adopts the best and most effective tech, thanks to the creativity of our engineers. Jota’s team of engineers usually burns the midnight oil to make sure you have the most effective machines. And the JT-SLT-900A high-speed thermal paper roll slitting machine doesn’t disappoint.

a)Ultrasound Edge Positioning Control

For starters, Jota’s JT-SLT-900A high-speed thermal paper roll slitting machine comes installed with an ultrasound EPC (edge positioning control). This means the machine automatically positions itself into the preset width sizes. This way, there’s no need for an operator, which further helps offer high slitting precision.

Say goodbye to crudely cut receipts. With the JT-SLT-900A high-speed thermal paper roll slitting machine, you’re saying goodbye to crudely-cut cash register receipts. There’ll also be no customer complaints that their receipts aren’t as smooth as expected.

It’s rather the opposite. Clients with POS paper roll businesses will appreciate and love the precisely cut receipts (parking tickets, ATM receipts, etc.). This also helps minimize losses due to non-smooth, imprecise receipts that usually become rejects.

b)Banana/Spreader Rollers

These are used in spreading the jumbo rolls uniformly, so there are no wrinkles and creases. This means you’ll be avoiding any overlapping problems, thus producing a till roll that’s smooth. The banana rollers are effective at making sure the cash register rolls are cleanly cut and without creases and at the same time preventing any interweaving. The rollers are made of anti-abrasive, nonstick and anti-static materials. This makes the rollers durable and capable of withstanding humid environments.

c)Fully Automatic Tension Controller

As a jumbo rolls slitter rewinder, you need the JT-SLT-900A high-speed thermal paper roll slitting machine to come installed with a fully automatic tension controller. It’s simple. All it does is control the machine’s tension speed and magnetic powdering.

By installing a tension sensor, a closed-loop control system is formed. Which makes it automatic. That is, once the roll radius is measured, the controller performs tension control based on the roll diameter.

Because it’s fully automatic, the controller continuously monitors the web tension as per the preset tension value. And you can see the true web tension on its LCD display.

d)Electromagnetic Brake

As expected, these are for safety purposes. At Jota Machinery, we get these brakes from Taiwan, and that’s because they’re trustworthy and very effective. The brakes use slow and stop motion sensors.

The electromagnetic disks operate by electrical actuation then transmit the torque mechanically. These make sure the brakes never fail.

Why Should I Buy the 900A Slitter Machine?

For starters, the JT-SLT-900A high-speed thermal paper roll slitting machine is a highly productive machine. It can produce 30 to 45 pieces of the 57x50mm POS until it rolls in 1 minute, bringing up to 10,000 rolls daily. With such products, you’ll be increasing profits and thus expanding your business.

And as a medium-priced slitter rewinder machine for cash register till roll, you don’t have to worry about the budget. Jota Machinery likes to think from the perspective of our target clients. This is why we came up with the JT-SLT-900A high-speed thermal paper roll slitting machine – to cater to customers looking for both quality and fair cost.

Therefore, as a wholesale supplier of thermal paper rolls, It’s wise to get one of these machines and have it installed to help cut the middleman. You get to create cash register rolls as specified by clients. And whenever a client makes a large order for the 80x80mm rolls, then you can deliver the order as fast as possible.

Since it’s a great investment, we help you through the process of investing in the slitting machine. We’ll hold your hand and show you the process of becoming the sole supplier of uniquely designed thermal paper rolls.

Jota Machinery values its clients, and so we prefer to work with you even after selling the JT-SLT-900A high-speed thermal paper roll slitting machine. We don’t leave alone to struggle with the challenges of supplying specifically-designed rolls. We even send agents to your shop to help you out with the machine. And we’re always available for any consultation.

Apart from the investment side of things, the other reason why you should get the JT-SLT-900A high-speed thermal paper roll slitting machine is the amazingly efficient features that come with it. For instance, the JT-SLT-900A high-speed thermal paper roll slitting machine winding tightness is adjustable. The machine is equipped with a precision regulator, which means you can adjust its tightness as you need.

At the same time, the JT-SLT-900A high-speed thermal paper roll slitting machine has been designed to avoid problems of overlapping through its banana/spreader roller.

How Does the JT-SLT-900A high-speed thermal paper roll slitting machine Work?

The process goes through six simple steps: unwinding, web feeding, slitting, rewinding, waste removal, packaging.

The first stage involves unwinding the jumbo paper roll, which readies it for the slitting section. Tension is the most important factor to consider. It’s how straight, and firm the thermal paper jumbo roll is and makes sure it doesn’t break during slitting.

The next step is the web feeding process. It’s where the jumbo paper roll enters the slitting section. It consists of rollers that hold the web of paper and direct it to the slitter head. The web is held at a constant angle and tension. This is to ensure that the web does not break or deform.

Once the jumbo roll is well fed into the slitter section, the cutting takes place. The cut is done to the required lengths and widths here; the round disc cutters are set according to the required lengths and widths. Jota thermal cash register paper roll slitting machine usually equips with a dual knives system.

After slitting the thermal paper rolls as per the settings, the roll goes to the rewinding section. The thermal paper went to the rewinding shaft and was wound to several pieces’ terminal rolls. Each smaller roll is rolled according to its end-use. Some rolls that are not needed immediately can be stored for further slitting when need be.

Ensure that you clear the rewinder section of any final product to prevent your roller cutting machine from clogging. Our cash register paper roll slitting machine comes with an automatic ejector.

The final stage is waste removal. This is at the rewinder section, where all the unwanted pieces can be removed. The slitter section also has a waste removal outlet. This allows wastepaper that is not needed to be removed. It is essential in ensuring that the paper roll machine does not clog.

Ensure that you collect all the wastepaper around the cash register roll slitting machine. This is essential in avoiding injuries related to slips, trips, and falls. Remember, a clean work environment is a safe environment.

What Makes Jota Machinery Better? Why Should I Go with You Guys?

Quality is the cornerstone of Jota Machinery gaining trust from customers around the world.

As Jota Machinery is the leading thermal cash register paper roll slitting machine manufacturer in China, there are over 1200 installations over the world, our rich experience in this industry could assist you greatly save time and energy.

Many clients suddenly contact us for small component replacement after 4-5 years of silence. Each time we receive such mail, we could feel the client’s satisfaction overflowing from each word.

https://youtu.be/lBMMnl4tduo

Also, we have a CNC center where we get to test the machines before selling them. This helps us identify potential challenges that clients may encounter.

In terms of pricing, we are fair. You don’t have to worry about taxes, even though they’re included in our process of determining the machine’s pricing. That’s why Jota considers all your financial needs, so we may settle on a price that’s reasonable to you. Just know that Jota Machinery always has your business’ best interest at heart.

How Much Does the 900A Cost?

We understand that shipping cash register paper roll slitting machines can be hectic. This is because the machines are usually a bit huge. They also attract slightly higher tax and shipping charges.

To minimize your costs, we ensure that we connect you with the best shipping agents. There are a number of reasons that may affect the slitter’s price. For instance, the customizations you may need usually affect the prices.

The price of your thermal paper roll slitting machine depends greatly on its features and from where you are buying it. Different countries offer you various prices for the thermal paper roll slitting machine.

The cost for the 900A slitter machine is also dependent on the size of the machine. For example, if you are to buy a jumbo thermal paper roll slitting machine, the cost of its tiny till roll will be determined by the cost of a jumbo thermal paper roll.

Moreover, the cost will change depending on market conditions. To get a quote for a jumbo thermal paper roll, you can either contact us directly or contact well-known thermal paper jumbo roll providers from your nearest location or the suppliers around the world.

Are There Any Testimonials of Satisfied Clients Who Have Used the 900A Slitter?

Yes, we do. Jota Machinery has sold the JT-SLT-900A high-speed thermal paper roll slitting machine to various clients. And one of our biggest clients is Navigator, a famous brand in Portugal. The company was so pleased with the JT-SLT-900A high-speed thermal paper roll slitter rewinder that they gave us positive feedback on the machine’s quality and effectiveness. They also loved our post-purchase services, especially where we reached out to confirm how the machine works and whether the slitter is a profitable machine to have.

We also have positive feedback from other countries like Saudi Arabia, Mexico, Kenya, Japan, etc. You can learn from their experiences. Send us an inquiry on our website, and we’ll share the info.

How Fast Can You Deliver to the United States?

Since the JT-SLT-900A high-speed thermal paper roll slitting machine is a fairly heavy machine, we deliver within 3 to 4 weeks. But it mainly depends on the state where you’re located. Because we’re headquartered in China, deliveries closer to home are usually very fast. And we send agents to help out with the installation and how it works.

Even though Jota Machinery doesn’t have agents in the United States, we can still deliver the 900A slitter machine via DHL or TNT in the fast express. And whenever you need technical support, we’re always available to connect via Zoom or any other video call app.

So feel free to contact us and help us make an order.

We Jota could also supply the following related machines, if you are also interested in any type, please feel free to send us an inquiry:

- Hot Melt Thermoplastic CFRP CFRTP Prepreg Manufacturing Machine

- Automatic Facial Tissue Making Machine

- Fully Automatic Toilet Paper Maker

- Plastic Film, Fabric, Aluminum Foil Slitting Rewinding Machine

- Paper Sheeter

- Paper Tube Making Machine

- CFRP CFRTP FRP Prepreg Slitter

- Paper Drinking Straws Machine

- Label Die Cutting Machine

- Flexo Printing Machine

- Cardboard Tube Cutting Machine