Thermal Register Paper Roll to Roll Slitting Machine

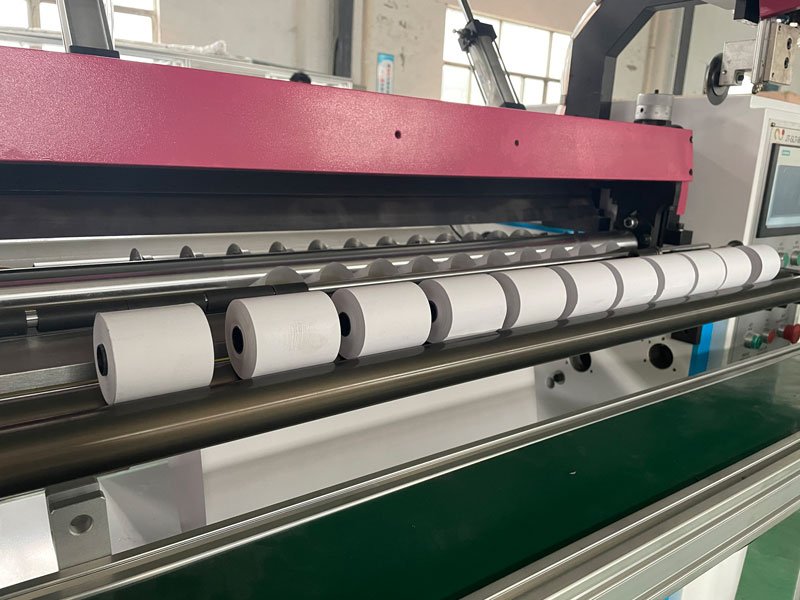

- 3″(φ76mm)Air Expanding Shaft Suits for Most Use Paper Tube Diameter

- Automatic Paper Core Loading Machine

- Fully Automatic Tail Cutter and Gluer Device

- Optional Thermal Paper Conveyor Packing Line

- Adopts 37mm Thickness Machine Wall

- Specification

- Video

| Model | JT-SLT-900 |

| Description | Thermal Register Paper Roll to Roll Slitting Machine |

| Color | Can Customized |

| Max Jumbo Roll Width | 900mm |

| Max Jumbo Roll Diameter | 1000mm |

| Max Rewinding Diameter | 160mm |

| Min Slit Width | 25mm |

| Max Speed | 150m/Min |

| Unwinding Stand | 3-Inch Air Expanding Shaft |

| Rewinding Shaft | 0.5”, 1” Are Available (Or As Your Request) |

| Voltage | 3 Phase, 4 Wire, 380V/220V (Can Customized) |

| Power | 2.9Kw |

| Weight | 1200kg |

| Essential | Air Compressor, Jumbo Roll, Inner Core |

| Optional | Cash Register Till Roll Packing Line,Inkjet Machine |

| Section | Items |

| Unwinding Section | Φ 3-Inch Air Expanding Shaft |

| Auto Jumbo Roll Chain Lift Loading System | |

| Electromagnetic Powder Brake | |

|

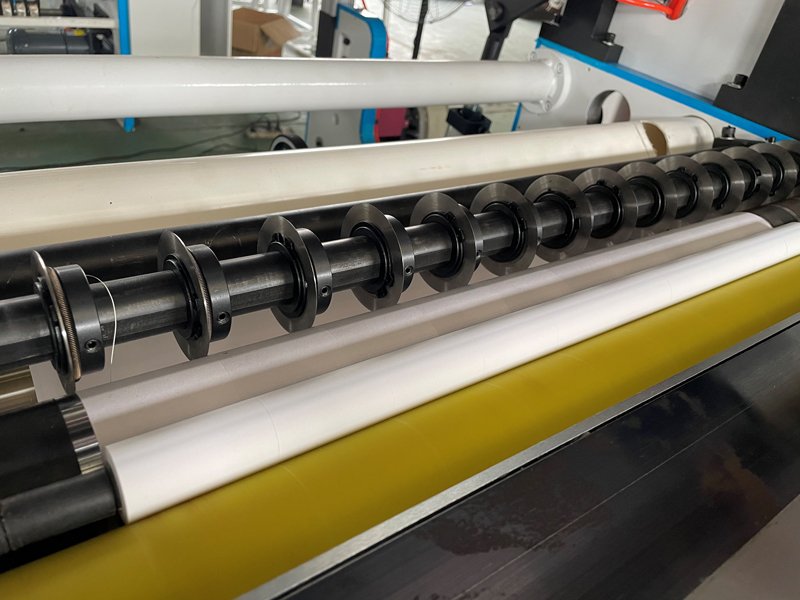

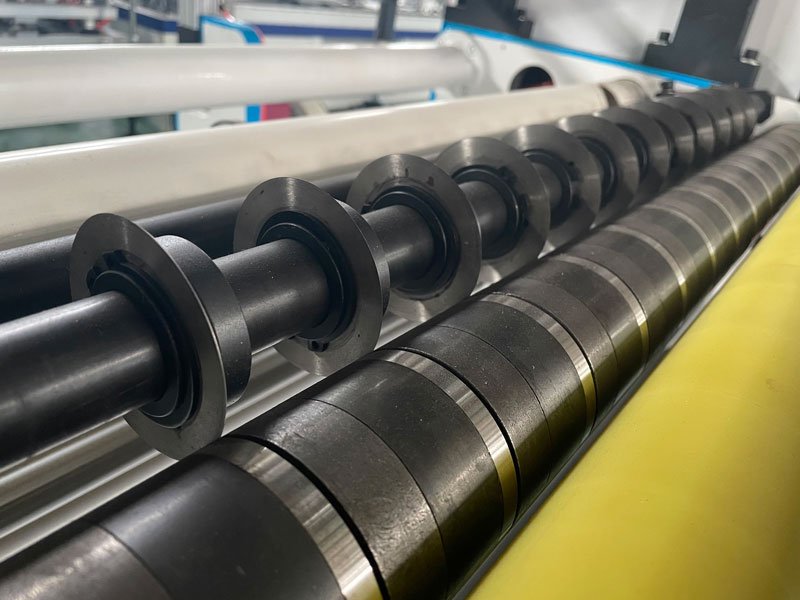

Sitting Section | Disc Slitting Blade: Upper Blade And Lower Blade |

| Spacer In Lower Blade To Adjust Slit Width | |

| Rotatory Meter Counter | |

| Auto Tail Cutter And Gluer Device | |

| Auto Waste Edge Tube Trimmer | |

|

Rewinding Section | Φ 0.5-Inch Φ 1-Inch Rewinding Shaft, Other Size Is Also Available |

| Red Line Device To Mark When Nearing End Use | |

| Auto Tucker For Quick Start Rewinding | |

| Pressure Roller To Avoid Overlap Issue | |

|

PLC & HMI | Siemens PLC |

| Siemens HMI. Speed, Tension, Meter All Shows On It | |

| Auto Stop When Reach The Pre-Set Meter On Touch Screen | |

| Schneider Electronic Switch |

Thermal Register Paper Roll to Roll Slitting Machine

You’ve bought jumbo rolls to step in the paper market and confused which type of slitting machine need to buy or which supplier have economic price and good service? Then we recommend us Joa Machinery.

Jota Machinery is a paper converting manufacuturer founded in 2002, we located in beautiful city Kunshan. Due to specical location you only need to take about 1 hour trip from Shanghai to our factory.

Thermal paper jumbo roll: width:795mm Length:8000m Gram:55GSM

Thermal paper slitter rewinder is the best machine to suit your jumbo paper rolls business.It has an advanced machine equipped with an auto-core hopper that works to store the large mass raw material.

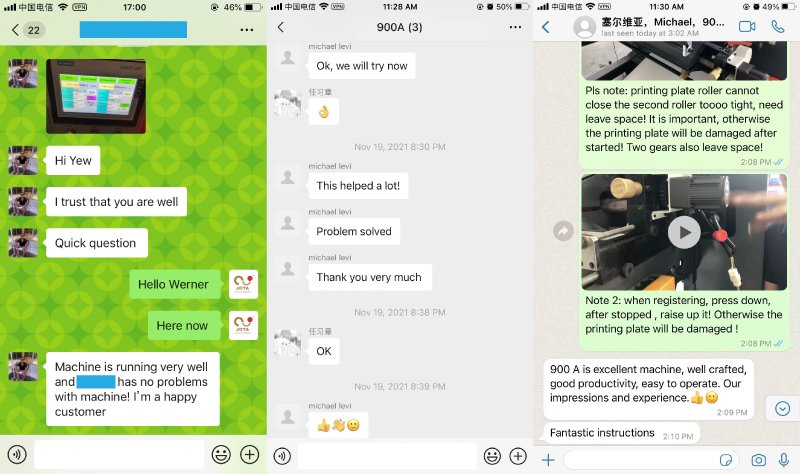

Feedback from clients whom purchased thermal paper slitting machine from us

Let’s further dive into the article to have a better understanding of the thermal paper slitter machine with auto-core hopper.

- What is a thermal paper slitter rewinder with auto-core hopper?

- How does a thermal paper slitting machine with hopper works?

- What are the features of the thermal paper slitter rewinder machine with auto-core hopper?

- What are the types of thermal paper slitter rewinder?

- What optional equipment can I add to my paper slitting rewinding machine?

- How to find best manufacturers of the thermal paper slitting rewinding machine with auto-core hopper?

- What are the benefits of paper slitting rewinding machine?

- How is thermal paper slitting rewinding machine with auto-core hopper is made?

- Is Jota’s thermal paper slitter rewinder certified?

- Can I customize my thermal paper slitter rewinder with auto-core hopper?

- Is there any maintenance guide for thermal paper slitting rewinding machine with auto-core hopper?

- How can I run a thermal paper slitting rewinding machine business?

- How to place order for thermal paper slitter rewinder at Jota?

What is a thermal paper slitter rewinder with auto-core hopper?

Thermal paper slitting machine with a hopper used to make little slits in a huge paper roll.

You can adjust the width of the slitter according to your needs. The procedure begins with the unwinding of a big paper roll.

The paper roll is fed through sharp knives, forming a paper web. Sharp cutters slit the enormous paper web into slits of predefined width.

The slits rotate to make little paper rolls with the help of the rewinding unit.

Nowadays, a double inverter motor is used to power the slitting rewinder machine.

When the winding diameter increases, an inverter motor is used to achieve a specified magnetic powder friction while avoiding excessive temperatures.

A powerful motor drives the rewinding and unwinding shafts in a typical slitting rewinder.

On the rewinding and unwinding shafts, an electromagnetic clutch and brake are installed, respectively.

Adjusting the electromagnetic clutch and brake’s current controls the torque of the rewinding and unwinding shafts, which is subsequently used to control the web tension.

Electromagnetic clutches and brakes are special automatic actuators that transmit torque via magnetic powder poured in the internal gap of the actuators.

The magnetic state of the magnetic powder can be changed by changing the excitation current, modifying the torque communicated.

Cutting and slitting machines are continually evolving from single-motor control to 2-motor and 3-motor control, with quicker machine speeds resulting in more stable and efficient operation.

Figure 1: Thermal Paper Slitter Rewinding Machine

Thermal paper slitting machine parts

All parts of the machine are very significant and you must know about their separate working to have a better understanding.

Following are the parts of the thermal paper slitting machine with an auto-core hopper.

Slitting unit

This portion slits the wide jumbo roll into multiple narrow strips.

It is mostly made up of the upper knife roller, lower knife roller, upper blades, lower blades, spacers, and other major components.

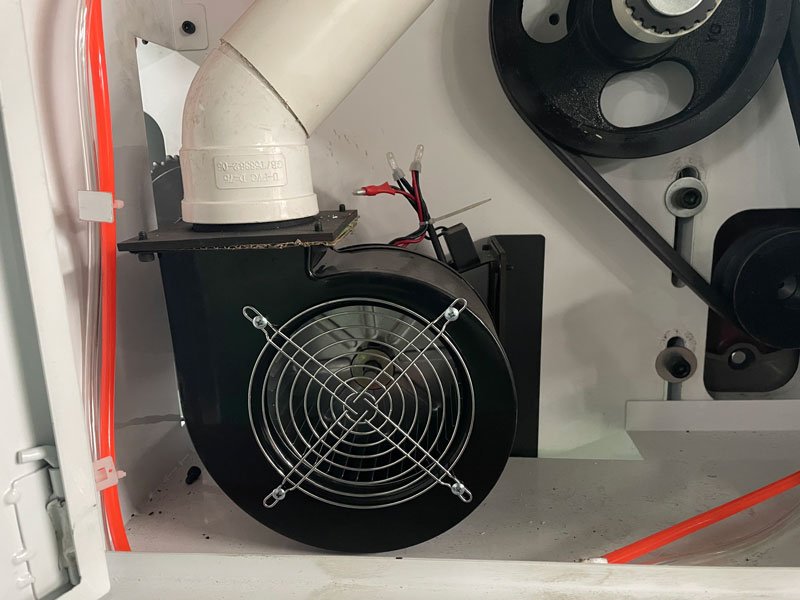

Disposal unit

It is primarily used to gather waste, with common ways include blowing off trimmed waste using a blower and using an independent waste edge rewinding gear, among others.

Rewinding part

It is primarily made up of winding shafts and a winding motor, with the thin strip cut after slitting being attached to the winding shaft. It is twisted into a small roll of a specific diameter in accordance with the rotation rewinding.

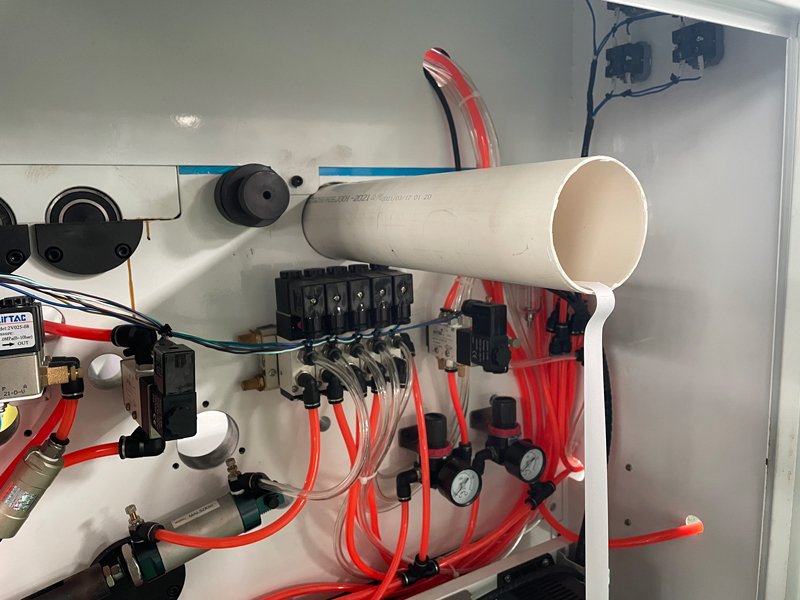

Control unit

It is primarily made up of key components such as a PLC, tension controller, and frequency converter.

It also has other components that act as the brain of the complete slitting rewinder machine. These components deliver commands to other machine components and ensuring orderly operation.

Web-feeding

This part is mostly made up of numerous idler rollers and drive motors. It is responsible for material feeding.

Unwinding

It consists primarily of an unwind stand, an unwinding shaft, a magnetic powder brake or an air brake, and other components.

It is used to transport jumbo rolls of various materials. The material feeding begins at the unwinding section.

Auto-Core Hopper

This is the new addition in the thermal paper slitter rewinder machines manufactured by Jota.

You can use the automatic hopper to either transport the material or store the massive raw material for your products.

It is a nozzle shape container and thus easy to use.

Figure 2: Slitter Rewinder Machine Parts

How does a thermal paper slitting machine with hopper works?

The jumbo roll from the papermaking machine is usually placed on the unwind stand, and the unwind stand’s braking gear retains the paper web at a constant tension.

After passing through idler rollers, the paper web is chopped into the desired width by circular slitting knives, and then rewound into small paper rolls according to the needed width, tightness, and diameter.

The primary parameters of a rewinder are web width, maximum speed, maximum unwinding diameter, maximum winding diameter, cutting process, and so on.

Slitting rewinder is the post-press processing equipment, and it generally refers to a processing technique on the slitting rewinder.

After the slitting knives cut the jumbo roll material, a sequence of plainly apparent fractures develops on the jumbo roll, and the jumbo roll is separated into narrow web strips.

There are three different types of cutting technologies.

- Crushing the cutting

- Unrestricted cutting

- Cutting with a shear

A rewinder machine’s job is to unwind already rolled material to a specific length and rewind it into a short roll of that length, which must fulfil the end customer’s specifications.

Simple rewinders are becoming increasingly rare on the market, while the thermal paper slitter rewinder machine, which combines the slitting and rewinding tasks, is becoming increasingly popular.

Figure 3: Working of a Slitter Rewinder Machine

What are the features of the thermal paper slitter rewinder machine with auto-core hopper?

There are several features of the thermal paper slitter rewinder which are as below.

- CNC processed machine components

- Automatic tension control system

- Discharging tray for edge wastage

- HMI PLC control system

- Pressure regulators

- Surface rewinding

- Automatic meter counting

- Proactive motor driven round blade cutting

- Siemen’s inverter motors

- Youdao ultrasonic EPC system

- Hydraulic shafts

- Taiwan’s pneumatic powder brakes

- Banana rollers

What are the types of thermal paper slitter rewinder?

Depending upon the type of use and latest trends, your thermal paper slitter rewinder has the following types.

Surface friction rewinding machine

- The rewinding shaft of a surface slitter rewinder simply revolves against one or more motor-driven drums, which are proactive and drive the rewinding shaft rotation.

- The surface slitter rewinder can usually only wind the material in one direction and must rely on the nip roller to complete the rewinding process.

- Surface slitter rewinder is primarily used to wind large diameter elastic or inelastic materials rolls, but these materials must not be too sensitive to nipping or compressing, such as textiles, paper, and nonwoven fabrics.

- Rewinding delicate materials with a surface slitter rewinder is not recommended.

Centre rewinding slitting machine

- It is the most often used slitter rewinder for paper. The differential friction shaft or air expendable shaft is driven by a motor in this machine.

- It signifies that the rewinding material’s core generates the winding force.

- If you work in the printing and packaging business, you can benefit from this machine.

- Variable materials, such as paper, cardboard, sticky labels, kraft paper, aluminium foil, plastic films, and so on, can be slit.

- In this machine, the motor-driven rewinding shaft turns itself, generating torque and tension in the middle slitter winder.

- Air volume between the nipping pressure roller and the rewinding shaft is frequently controlled by pressure rollers.

- It’s ideal for winding nonwoven textiles and delicate, soft, uneven-thickness webs, such as nipping-sensitive plastic film or composite webs.

Apart from these two machines, there is a single machine performing these two functions which is called center rewinding and surface friction rewinding machine.

What optional equipment can I add to my paper slitting rewinding machine?

Jota not only manufacturers a simple thermal paper slitter rewinding machine, it also provides you the option of equipping your machine with various components.

This offer helps you save your cost from buying other sets of machines.

Your auxiliary equipment for slitter rewinder includes;

Inline printers

The inline printers have been proved very beneficial from the past few years. Jota installs inline flexo printers with the help of which you can print on your papers.

Thermal Paper Printing Slitting Machine

The printers use thermal ink for printing and you can print in 3 to 8 different colors.

Automatic tail cutter and gluer

Although, your thermal paper slitter rewinder has cutting shafts that cut your papers. You can also add automatic cutters and trimmers to set the diameter of your paper rolls.

Further you can use these cutters to form smaller rolls such as for cash receipts and billing papers.

Auto-core hoppers

It is always difficult to carry the mass storage, and placing the raw material. Auto-core hopper have aided this need.

They have sleek opening which allows the easy flow of raw material into the machine. As it is automatic, it’ll close itself after giving the required mount of the material.

Moreover, you can transfer your stuff from one place to another with the help of these hopper.

These are made of steel and don’t get damaged due to environmental conditions.

The auxiliary equipment jota provides is not only cost-effective, but it also reduces the manual labor.

You can visit our workspace and choose the equipment by yourself.

Thermal Paper Conveyor Packing Line

When place the finshinshed small roll to thermal paper conveyor packing line the small till roll will firstly pass roll cut off device, then enter to hammer device at last going to packing machine. Before packing the hammer device will punch the plastic core to the small roll to ensure the surface quality. We suggest you equipped one line to do thermal paper business

Figure 4: Auxiliary Equipment

How to find best manufacturers of the thermal paper slitting rewinding machine with auto-core hopper?

With the help of latest technology, finding the best manufacturer has become very easy. However, you need to stay away from the scams.

Jota machinery is one of the top-notch manufacturers of thermal paper slitter rewinder with auto-core hopper.

As this is the newly designed feature, its demand is increasing. We recently exported this machine to one of our clients.

You can place your order by visiting our web page. Apart from thermal paper slitting machine, you can also visit and order other products manufactured at jota.

What are the benefits of paper slitting rewinding machine?

Thermal paper slitter rewinders play a milestone in the paper industry. Without the aid of these machines, the paper making prices would be very difficult.

There are a lot of benefits of this cost-effective machine. These are as under.

- These simple-to-use paper slitter rewinders allow you to easily enter data into the control panel using the touch screen.

- It is a more efficient and secure method of rolling the items.

- Unwinding and rewinding automatically saves time and reduces the possibility of wrinkled paper edges.

- With your paper slitter rewinder, you can serve a variety of industries, from tissue paper rolls to sticky tapes, laminating film rolls to kraft paper rolls.

- Because of the long-lasting paper rolls, paper slitter machines have enabled several companies to boost their output.

- It is a cost-effective method that saves you money on labour costs.

- Automatic operation, along with lower labour costs and improved mass manufacturing, resulting in lower-cost products.

- You have the option of customising the dimensions of the slit reels.

- With the help of high-speed rewinders, you may produce hundreds of slit rolls.

- These machines are long-lasting and dependable.

How is thermal paper slitting rewinding machine with auto-core hopper is made?

To make your paper slitter rewinder, Jota machinery uses a precise production method. The meticulous method aids in the development of cutting-edge machinery. The steps in the production process are as follows:

Designing

The design of your machine is the initial stage. Jota Machinery creates the machine based on your specifications.

Disclose the design of your ideal slitter rewinder to our engineering staff. You can also download a PDF version of your machine design.

Whether you choose a standard or bespoke design, Jota’s engineers and R&D team will provide you with unique and innovative features.

Assurance of high quality

We take the raw materials and components from reliable sources. Before the process begins, the quality control team rigorously inspects each component.

The production procedure begins after the approval.

Assembly

The machine components are assembled by a skilled technician.

Each component is properly assembled using the engineering diagrams given.

Connections to electricity

Electrical components are installed properly by the electrical engineering team, in addition to mechanical engineering.

Sensors, an EPC system, and an automatic tension control system are installed for accurate automatic operation.

Electric Pannel

Testing is now complete.

Engineers take over your machine after it has been assembled and thoroughly inspect it.

After thorough testing in the factory workshop, your machine is packed and transported for delivery.

Is Jota’s thermal paper slitter rewinder certified?

Yes, your thermal paper slitter rewinder with auto-core hopper is certified.

Jota’s all the machines meet the international standards. They are certified with CE certificates and legal business certificates.

We have gained trust of thousands of customers abroad.

Jota’s certifies machines are safe for you to use.

Figure 6: CE certificate

Can I customize my thermal paper slitter rewinder with auto-core hopper?

Keeping in mind the needs of the customer, Jota provides full customization services. You can handle variable-sized paper rolls with the help of a thermal paper slitter rewinder.

Similarly, Jota gives you flexibility when it comes to the size of the smaller rolls.

The technical data for Jota’s paper slitter rewinder includes Unwinding roll widths range from 350mm to 800mm.

It has unwinding diameters that range from 1000 to 1500mm.

The rewinding diameters range from 800 to 1500mm and unwinding/rewinding speeds range from 200 to 500m/min

You can watch the following video for more understanding of the machine.

Figure 8: Customization

Is there any maintenance guide for thermal paper slitting rewinding machine with auto-core hopper?

If you purchased your paper slitting equipment from a trustworthy manufacturer, they will be able to assist you with any improvements or replacements that are required.

Your rolling machine’s ability to last longer is largely reliant on how well you maintain it.

Your paper slitting machine must be properly cared for and maintained if it is to serve you well.

The information in the accompanying handbook will help you better understand how to look after your roll slitting machine.

In addition to regular care and maintenance, you must keep an eye out for worn-out parts.

You may notice a drop in overall performance, as well as the need to replace worn-out replacement parts and other issues.

These are just a few of the warnings, but they should be enough to frighten you. If you’re having any of these issues, it’s time to upgrade your roll slitting machine.

How can I run a thermal paper slitting rewinding machine business?

JOTA also recommends certain business concepts in order to increase business profit. The following features are included in the plan:

- Preliminary market study

- Profit Assessment

- Choosing a Production Location

- Purchasing of Equipment and Raw Materials

- Recruiting Operators

- Business Marketing for Thermal Rolls

- Thermal Roll Business Maintenance and Expansion

Many foreign customers have profited from running this business due to the numerous advantages of paper slitting.

Similarly, if you buy two paper slitting machines and start making small paper rolls, the paper rolls you make will stack up like a mountain, boosting your business and allowing you to take on more orders.

Furthermore, cutting paper with a Jota slitting machine can earn you a lot of money, as people all over the world profit from using these machines.

Figure 8: Paper slitting Rewinding Business

How to place order for thermal paper slitter rewinder at Jota?

Placing order at jota is very easy.

Open google and go to Jota’s website.

Click the contact button and you’ll be ready to talk to our customer services staff.

You can place you order in minimum or maximum quantities.

For more queries contact our customer services team.

We Jota could also supply following related machines, if you are also interested in any type, please feel free to send us an inquiry:

- Hot Melt Thermoplastic CFRP CFRTP Prepreg Manufacturing Machine

- Fully Automatic Thermal Paper Roll Slitting Packing Machine

- Fully Automatic Toilet Paper Maker

- Automatic Facial Tissue Making Machine

- Plastic Film, Fabric, Aluminum Foil Slitting Rewinding Machine

- Paper Sheeter

- Paper Tube Making Machine

- CFRP CFRTP FRP Prepreg Slitter

- Paper Drinking Straws Machine

- Label Die Cutting Machine

- Flexo Printing Machine

- Cardboard Tube Cutting Machine