High Configuration Film Packing Machine

- Fully Automatic

- Easy Operation

- Europen Standard

- Beautiful Layout And Small Space

Get an Instant Quote

Heat Shrink Film packaging Machine

If you are now seeking a fully automatic thermal paper production plan then we recommend you try our heat shrink film packaging machine.

This set machine can help you automated pack the small roll to finished goods you need.

Feel free to contact us for more details

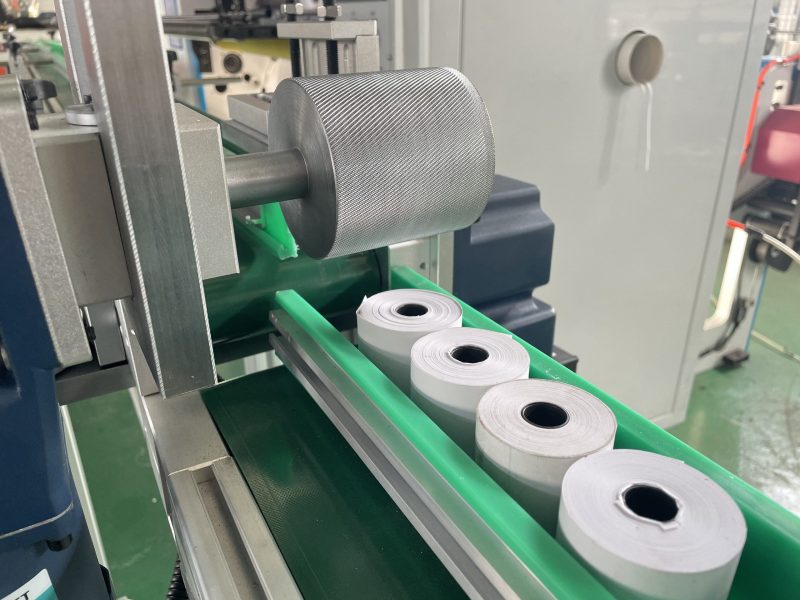

Packaging process for heat shrink film packaging machine

Normally this set machine is combined with the conveyor line then becomes a production line.

The detailed working flow is like below:

Convery – Small roll cut off – Hammer – Sealing – Heating

Machine Characteristic

- All famous brand parts

- Anti-corrosion structural material surface spray or nickel plating treatment

- The seal is not only stable but also has low noise

- Adopt anti-stick and high temperature resistant alloy sealing knife

Machine Feature

- Banana roller to avoid the overlapping issue

- Round slitting blade for cutting paper

- Special Vertical pressure roller

- Optional thermal paper packing line

- Focus Factory

- Dear Customer

- Professional Team

Tutorial

What's should need for the packing machine?

You need double layer POF shrink film for packing machine.

What's the power for this machine?

The power for this machine is 3 Phase, 380V.

Did this machine need air?

Yes. Not only packing machine need air, our thermal paper slitting machine also needs air support.

Can your packing machine suits for the slitting machine i used now?

This machine can use independently.

Contact Our Support Team

Operation Manual For JT-SLT-1400C Slitting Machine

Installation space

- Device dimension: 3.4m x 2.1m x1.9m (L x W x H),

- For operating and maintenance space, 2m space to each side of the device is recommended;

- Device weight: 3800kg;

- The floor should be clean and flat.

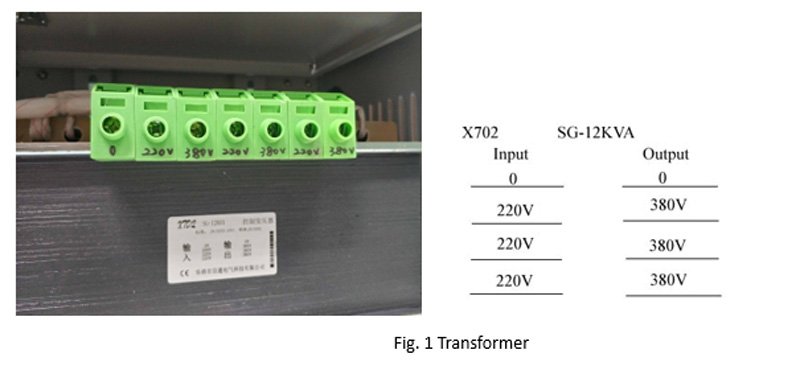

Power supply: 6KW

- There is a transformer together with the JT-SLT-1400C device. It requires 3 phase 220V input. And the total power consumption is 6KW.

- Warning: experienced electrician is required.

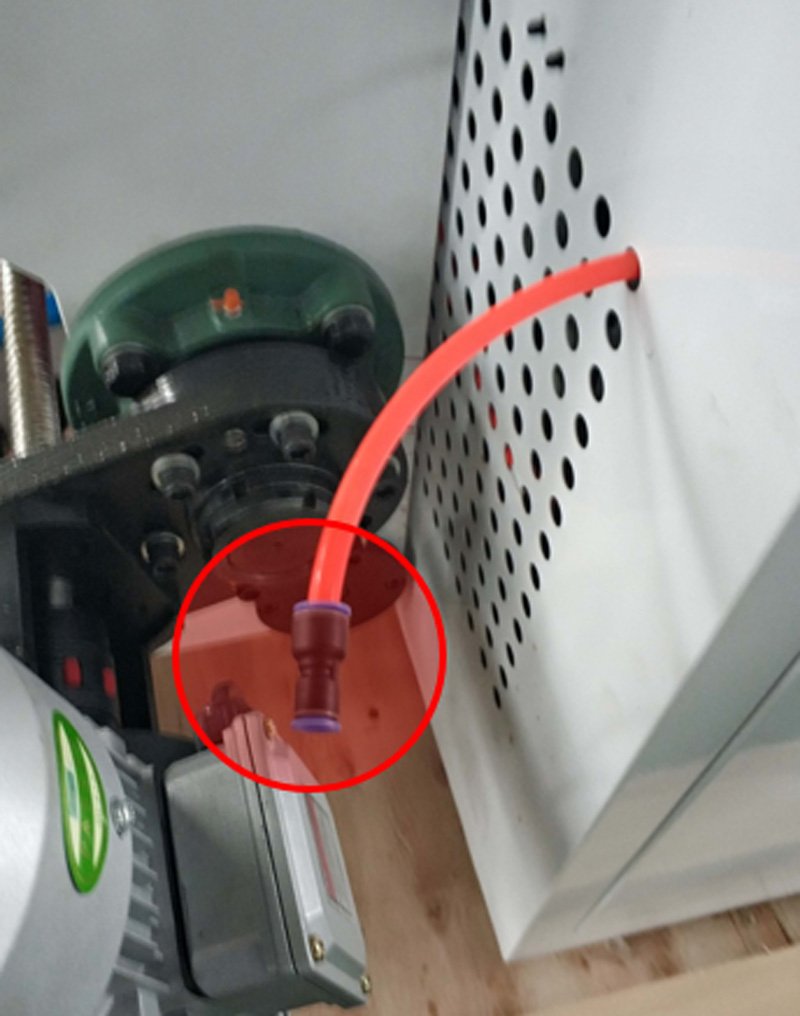

Compressed air

- Requirement: 0.6MPa continuous air supply, free of oil and water.

- A quick connector is equipped. The customer needs to prepare an air tube to connect air to the machine. The connector hole diameter is 8mm.

Antiwear Hydraulic oil

- Enough antiwear hydraulic oil is required to fill the tank.

Lifting truck

- Lifting truck capability should be higher than 4 Tons.

- Package Weight: 4000 kg

- Pallet size: 3.8m x 2.21m

Materials

- Paper reel for slitting

- Roll cores for rewinding the slit paper

Leveling gauge

- A leveling gauge is requested to level the machine when installation.

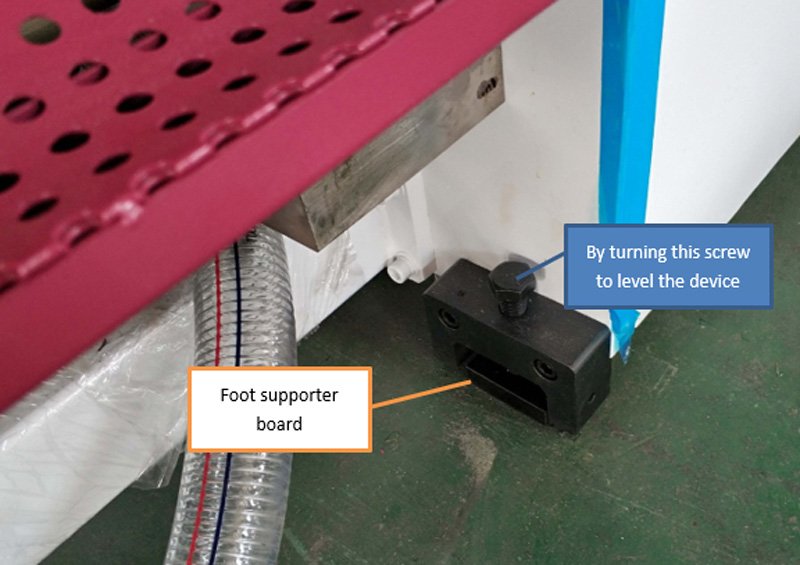

Positioning and leveling

- Move the device to the installation site.

- Put the foot supporter board to support position, by turning the screw to position and level the device. There are 4 support feet to support the machine.

- The leveling gauge should be set on the device’s main driving roller.

Shipping locks

- At the backside of the device, there are two shipping locks to protect the movable part, and they should be removed when installing the machine.

- The metal rollers are wrapped by film, please remove all the wrapping film.

Connect the waste removal unit

- Assembly the Waste removal unit Y-tube;

- Connect the PVC steel wire pipes to the waste removal unit;

- Connect the power connector to the left-down side of the main device;

Connect the main power

- The main power connector is located on the right side cover. The power supply should come from the transformer.