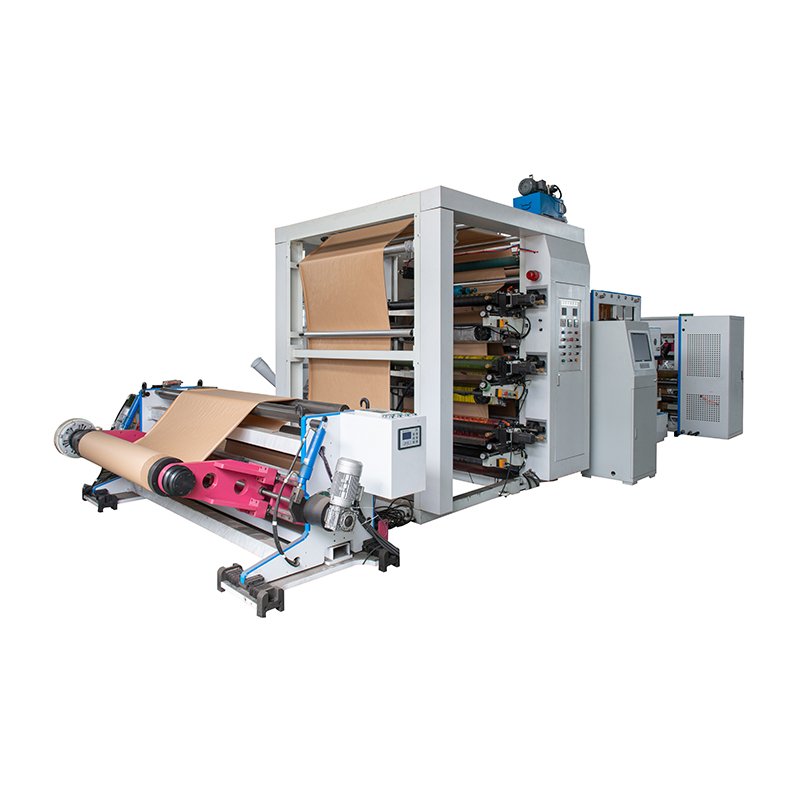

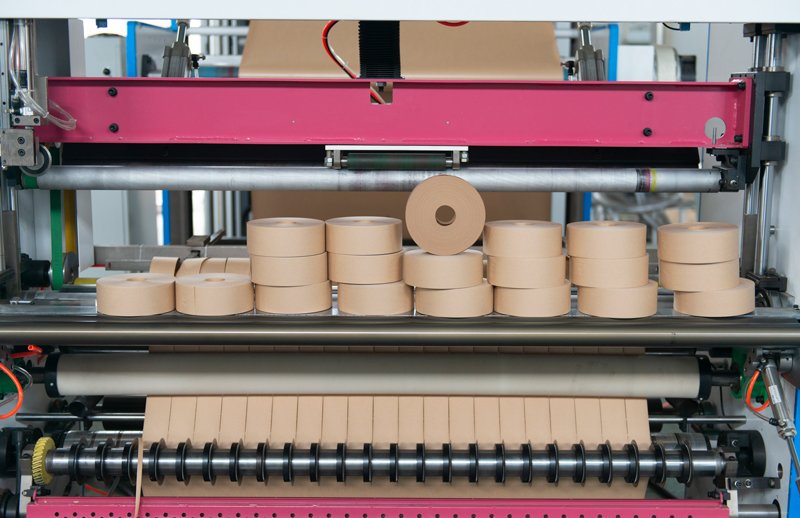

WAT/Water Activated Tape Slitting Machine

- 1400mm Water activated gum tape slitting machine

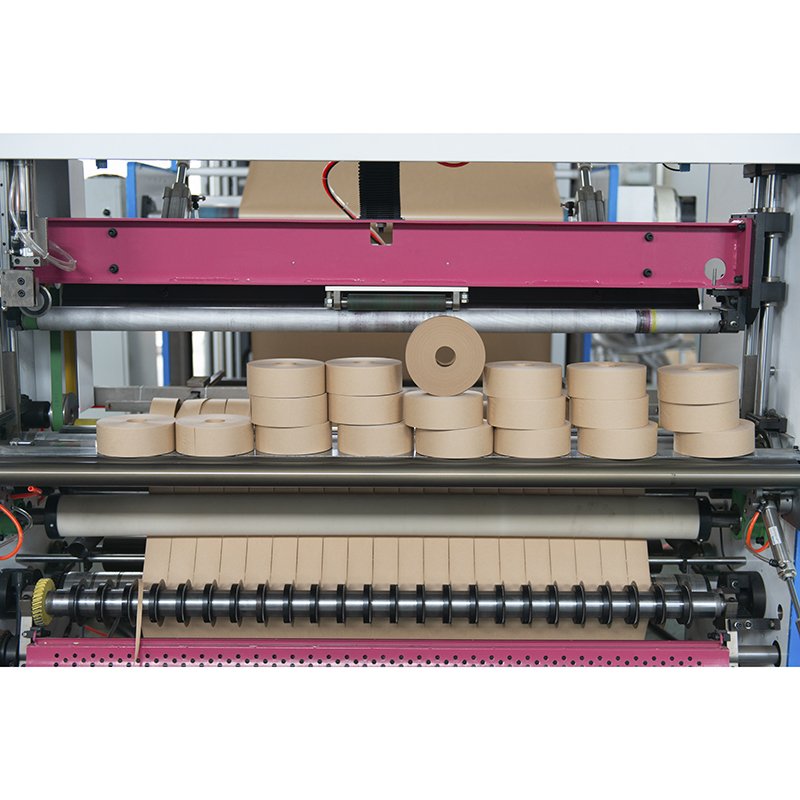

- 55% more small roll output than 900mm width machine

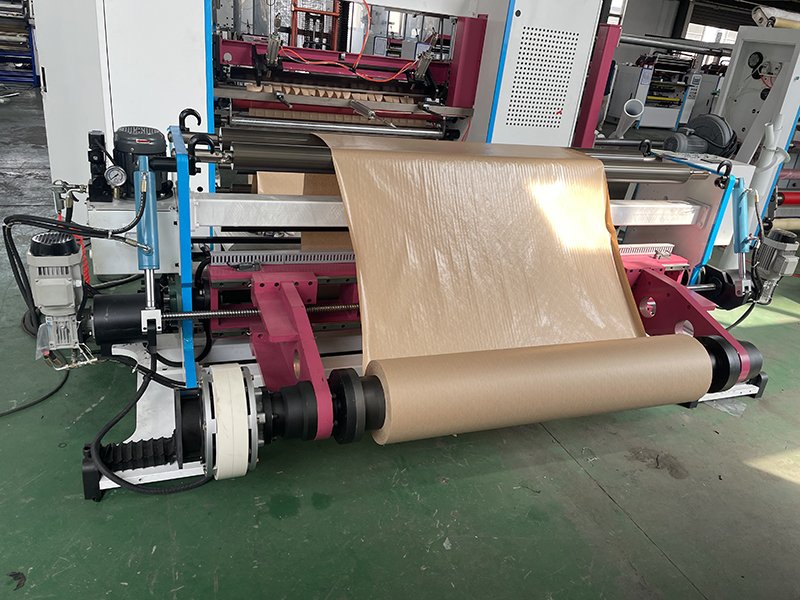

- Shaftless unwind stand

- Hydraulic jumbo roll loading

- Photoelectric sensor web guiding

- Anti-overlapping banana roller

- Specification

- Video

| Parameters | |

| Item | JT-SLT-1400C water activated gum tape slitting machine |

| Max. Rewinding Diameter | 300mm |

| Min. Slit Width | 30mm |

| Web Diameter | 1200mm |

| Web Width | 1400mm |

| Max. Speed | 300m/min |

| Unwinding Shaft | 3″ (76mm) air expanding shaft |

| Rewinding Shaft Diameter | 0.5″, 1″ (size customizable) |

| Total Power | 9.5Kw |

| Voltage | 380V/50Hz |

| SPECIFICATIONS | |

| Water activated gum tape slitting machine is especially suitable for making gum tape rolls, gummed tape rolls, kraft paper tape rolls, cash register rolls, ATM rolls, ECG rolls, POS rolls, till rolls, etc. | |

| Unwinding Section | Shaftless hydraulic jumbo roll loading unit. |

| Fully automatic tension controller. | |

| 20kg/m2 electromagnetic brake from Taiwan. | |

| Photoelectric sensor web guiding. | |

| Direction adjustable balancing roller ensures the roller itself always keep in tight touch with the whole web. | |

| Printing Section | 1-4 colors optional |

| Ceramic Anilox cylinder transferring the ink, long life, wear resistance, corrosion resistance | |

| Dancer roll integrated buffer | |

| Automatic web guiding system | |

| Infrared drying units | |

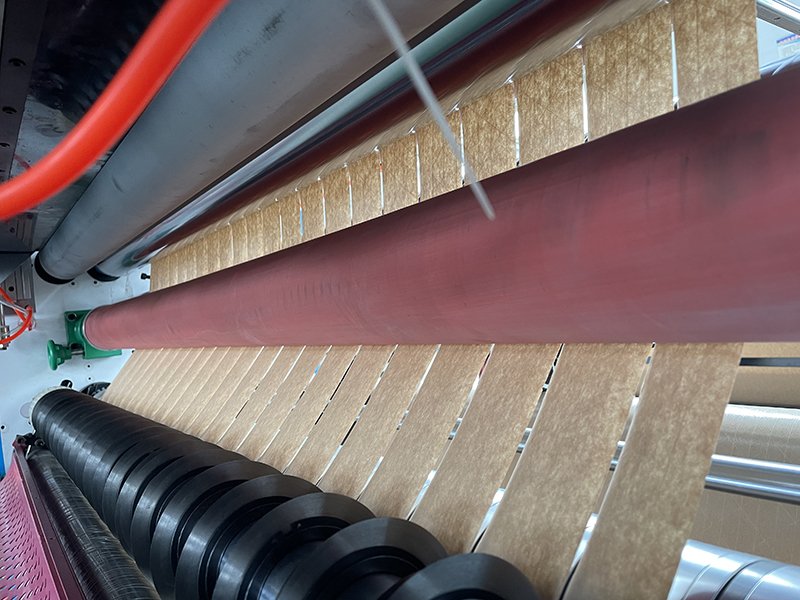

| Slitting Section | The upper circular knives are fixed by screws, and the lower circular knives are fixed by an aluminum spacer, which ensures cutting precision. |

| The rotary encoder automatically metering slit length. | |

| Rewinding Section | Automatic tucker tucks the tail, convenient for quick trigger rewinding. |

| 90° vertical lay-on roller, capable of moving up and down, ensures more balanced left and right pressure, wider rewinding diameter could be realized. | |

| Overlapping problems could be avoided with a banana roller. | |

| Controlling Section | Siemens PLC module, touch screen, and graphic user interface (HMI). |

| Yaskawa AC drives for Siemens master motor. | |

| Schneider low voltage electrical appliances. | |

Waste Removal | Edge waste blower through expulsion tube. |

| Optional Parts | Safety guard. |

| 4 corners emergency switches. | |

| Transmission belt. | |

| Shredder. | |

| Safety fence. | |

What is the water activated gum tape slitting machine?

Jota Machinery sold one set water activated gum tape slitting machine to Serbia in 2021.

This set machine is 1400mm you can make the colored WAT gum tape easily by JT-SLT-1400C.

Let us open the topic with this water activated gum tape slitting machine. After reading this article I can ensure you will be professional in the packing field.

If you are running a business online or you simply need to ship an item somewhere, you always have to face the dilemma of how to seal your packages to ensure they are safe.

There are many ways you can seal items for shipping, but using a water-activated gum tape is the best way to ensure the products will be safe.

Known by a variety of names such as:paper tape, gum tape, or gummed tape … water-activated gum tape is primarily made of paper and has multiple layers of synthetic fibers or polythene strings for added strength.

A water-based chemical adhesive is then used to help the tape bond to the surface of a carton.

Water-activated tape is often the best option for sealing and closing boxes.

Not many people are familiar with it, but you have probably seen it if you have ever ordered something online.

They are mostly made of white or natural colored paper and pretty hard to open. This difficulty is part of its charm as a sealing tape.

Businesses also love it because it is customizable hence a great choice for branding packaging.

How does water-activated gum tape work?

Water-activated gum tape can also be made of plain kraft paper.

They normally come in 3 inches to 7.5c.m wide. The tape is first moistened with water before it is applied to any carton.

A capillary action adheres the tape to the fiberboard material creating a strong, durable bond that can withstand tough handling during transportation and shipping.

There are different ways you can wet and activate the adhesive on the tape. Sometimes you need to seal many packages meaning you will need equipment that moistens and cuts the tape faster. Here are some of the equipment you can use to apply a water-activated gum tape;

Sponge

Using a sponge is one of the simplest ways to dampen your tape and get it ready for use. This method is perfect for small businesses that do

not need to seal a lot of packages. Take your sponge and wet it, apply it to the tape to dampen it, and then use it to seal your chosen surface.

You may get a sponge alongside your tape order if you are lucky.

Manual Activated Dispenser

It can be pretty hectic for a bigger business to use a sponge to dampen the tape and cut the desired size yourself. The good news is that there

is equipment that will help you moisturize the tape and even cut it. This equipment is commonly referred to as a water-activated tape

dispenser. Water-activated dispensers come in two forms; Manual activated dispensers and electric dispensers.

A manually activated dispenser will roll out the tape across a wet sponge, and then you can cut it when it reaches your desired length.

Electric Tape Dispenser

This is the second and most useful equipment used to help in activating a larger quantity of tape for even bigger businesses. This equipment

automatically wets and cuts the tape to your desired length. If you need a whole lot of packaging done, then this is the perfect equipment to

purchase. It is fast and reliable.

Advantages of Using Water-Activated Gum Tape

There are many benefits to using water-activated gum tape to seal cartons, and many companies are swearing by it. Here are some of the advantages

Provides better protection against pilfering

Packages go through many hands before they get to their intended owners. Some people may be tempted to look through the carton’s

contents or even take something from the carton. Gummed tape not only makes it difficult to do so, but should someone try to gain access to

the box – the tape and the package will get torn. The seal is tamper-evident and will shred off if anyone tries to open the box.

Improves packer productivity

Unlike most tapes, where you have to use layers and layers of tape to ensure the package is secure, a single strip of water-activated tape is just

enough. Packers using other forms of tape, like pressure-sensitive tapes, have to go through the long process of using many strips of tape,

and this reduces their overall productivity.

Reinforces your Boxes and are good for branding.

One thing we love about water-activated reinforced tape is they provide a more secure bond to your packages. Another great advantage is

that they are customizable hence a great option for branded packaging. Instead of spending more resources on printing your logo on shipping

cartons, you can have your logo printed on the tape directly. You can personalize it with any message, design or logo you want—this helps

create a more professional, clean and personalized look for your cartons.

It is more profitable.

While water-activated tape is relatively more expensive compared to, say, pressure-sensitive tape, in the end, they are more profitable to use. For one, only one strip is enough to seal a package, unlike with other tapes that need 2 to 3 stripes or more. In the ned when you have to sell many packages, you will realize that it is cheaper to use a water-activated tape.

Another reason is that it minimizes worker injury saving the business a lot in operational expenses.

Water-activated tapes are easy to handle, and this reduces the risk of repetitive strain injury. Additionally, the fact that it protects packages from pilfering means that it helps to reduce theft cases which often come at a cost to the business. Considering all these factors, water-activated tapes are more profitable and would make more sense to a business.

Is water-activated tape eco-friendly?

The sustainability factor of water-activated tapes is also something that we have to consider. Most common packaging tapes use plastics or glossy waxes, which are not very eco-friendly. When large businesses use these

options like plastics, sellotape, or masking tape- it becomes bad for the environment.

The good news is that water-activated tape is completely eco-friendly. With many people becoming eco-conscious, you would be happy to know that water-activated tape has some eco-friendly benefits.

Here are some of the benefits;

- It is made from recycled material – Water-activated tape is made from completely recyclable materials. The paper can be easily gotten from a forest and is used sustainably. The tape is also biodegradable and compostable, meaning it does not contribute to waste and pollution.

In addition, it provides a very strong seal with only one strip, which makes it very sustainable.

- It has water-activated stickiness – Just as the name goes, it uses water to activate the adhesive that helps the tape bond to another surface and not harmful substances. You can simply turn the tape into adhesive magic by applying a little water. Since these tapes use water-activated stickiness to create a bond with a surface, they are very eco-friendly.

Most tapes use wax or gloss to help them stick to a surface. However, gloss and wax are non-biodegradable and not compostable. This makes them a nuisance to the environment.

- It uses soy-based inks – Businesses that tend to print messages or logos on their water-activated tapes often use soy-based inks compared to petroleum-based inks. Soy-based inks are great for a number of reasons. One, they are a renewable resource and will not leave any chemicals behind when they are decomposing.

The second reason is that they produce low volatile organic compounds (VOC), which helps to reduce air pollution as you print. The smell of petroleum inks can be so intense on the nostrils.

Jota Machinery’s water activated gum tape becomes popular due to widely marketing demand.

If you are now seek this slitting machine to produce WAT gum tape then feel free to contact with Jota Machinery