Your Ideal Thermal Paper Business Partner

- Working flow is from unwinding to packing this full progress

- Max running speed is 150m/min

- Unwinding stand can suit for the most used diameter of thermal paper jumbo roll

- Economic automatic thermal paper slitting machine with good configuration

Leading semi-automatic thermal paper roll slitting rewinding machine supper

Jota Machinery dedicated in doing semi-automatic thermal paper roll slitting rewinding machine more than 10 year.

Through our efforts, we have become partners of many well-known companies, nearly every country has our paper slitting machine, paper core cutting machine, paper core making machine etc.

We not only provide customized service but also provide full service for freshmen who want to do thermal paper business. You can contact us for more professional suggestions.

Visable Slitting Machine Quality

Semi-automatic thermal paper roll slitting rewinding machine adopts the famous brand of PLC, Electronic parts, cylinder, bearing, etc. to ensure the machine running quality.

Not only have a good configuration but also machine wall is also thickness than others. 45 mm can let you run the machine at high speed.

Semi-automatic thermal paper roll slitting rewinding machine

- Siemens PLC and HMI

- Japan SMC air valve

- Schneider Lower Switcher

- Automatic Operation

45mm Thickness Machine Wall To Ensure The Running Quality

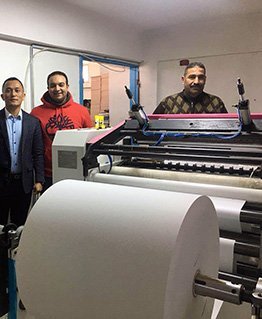

Professional Installation Team

Precision Produced From CNC Center

There Are Tight Connections Between Each Component

- Focus Factory

- Dear Customer

- Professional Team

The leading time is around 30-45 days, mainly depending on machine type.

Sure, it is our honor to work for you.

We will offer you some parts as backup, in case any part is broken within one year, we will sent you for free.

Sure, if we have client in your country, we will offer.

Semi-Automatic Thermal Paper Roll Slitting Rewinding Machine

As a bulk seller of semi-automatic thermal paper roll slitting rewinding machine, the work of your business unit is to buy and resell the merchandise to merchants and retailers or even other big industries, and at the end of the process, make a profit, right?

Well, if that is the case, you need to understand your product from start to end. Therefore, grasping frequently asked questions, entirely, is one of the best ways to understand what you will sell to the public.

Some of the essential questions regarding semi-automatic thermal paper roll slitting rewinding machine are as follows:

What accounts/descriptions and features does a semi-automatic thermal paper roll slitting rewinding machine have?

For a wide range of use, the purpose of this semi-automatic thermal paper roll slitting rewinding machine is to cut huge material rolls into sizes of your choice.

At Jota machinery, these semi-automatic thermal paper roll slitting rewinding machine are manufactured by our experts and seasoned professionals using high-quality constituents and brand-new latest devices.

Production of the machine is of high range and is severely tested by our lofty end production unit.

With low maintenance, rust resistance, and durability, our machine helps support the graphic and design industry throughout the world.

In general, our semi-automatic thermal paper roll slitting rewinding machine is used for rewinding and slitting all types of thermal paper rolls.

They consist of: cash register paper roll, till roll, ATM paper roll, adding machine roll, receipt printer roll, debit machine paper rolls, thermal fax paper rolls, ECG rolls, and many more.

Some of the features are;

- Static and dynamic drive roller balance.

- Electronic emergency switch.

- Automatic tucker, which promptly triggers rewinding.

- A lay-on roller helps in case of overlapping problems.

- Roll spacer, shrink film packing machine, automatic core loader.

- Unique control screen and Siemens PLC with all variables being shown on the screen.

- Round blades for automatic waste slitting and disposing of them by air by using an air blower via tube.

- Redline marking system, and others.

What are the Specifications of the Semi-Automatic Thermal Paper Roll Slitting Rewinding Machine?

The best semi-automatic thermal paper roll slitting rewinding machine should have the following variables and specifications.

- A web diameter of utmost 1000mm

- Total rewinding diameter of at least 160 mm

- The most appropriate voltage of 380V, 50Hz on 3-phase for the perfect semi-auto winding machine output.

- The average weight of around 2100 Kgs

- Comprehensive dimensions are as follows; 5212 by 2025 by 1680 (L by W by H) ● Rewinding staff depending on your needs 0.5”, 1.”

- Unwinding shaft 3” Air expanding shaft.

- A maximum speed of 150m/min

- The torque is 100 N.m

- The power is 25Kv

- The width of the web is 900mm

Those are just a sample of perfect specifications that a machine should have, and that is exactly what our semi-automatic thermal paper roll slitting rewinding machine of production is all about.

What makes our semi-automatic thermal paper roll slitting rewinding machine more distinctive than others?

Several reasons give us the upper hand in outweighing other competitors, these are:

A team of certified and skilled experts

Jota machinery has a solid reputation for 20 plus years in manufacturing high-quality semi-automatic thermal paper slitting rewinding machines.

Our team is of outstanding excellence; we ensure a one-stop production from thermal paper till roll packaging to thermal paper jumbo roll unwinding, on a single operation.

We entirely use the merits of the Chinese manufacturing industry chain, besides ensuring that our thermal paper slitting rewinding machine is too specific high-end quality machines.

Our ergonomic products are available to all potential buyers at market-leading prices.

As a result of the best quality and exclusive services, we have extensively reached out to far and wide customers globally.

Cost-effective semi-auto thermal paper roll slitting rewinding machines

Jota Machinery respects your budget therefore, we make it our goal to ensure that the prices of our machines are affordable so that we can accommodate a vast market.

That means it will, fortunately, assure you profitable margins for your semi-automatic thermal paper roll slitting rewinding machine.

Apart from the affordable prices of our products, we have used several methods of transactions whereby our patrons can choose to make payment with ease.

When it comes to functionality, you can operate our products either automatically or by hand; therefore, you will save on power costs, among others.

Taking advantage of the latest technology

The appropriation of the new technology is very useful in the manufacturers of almost all Jota semi-auto thermal paper roll slitting rewinding machines.

Apart from the high level of management and strong production capacity, we also embrace the advancement of technology in our day-to-day production.

You can take, for example,

All our products are online; consequently, any buyer can easily reach us through the same platform.

In other words, everything is almost done online without you coming to our premises, which in turn saves on cost and time.

What is the flexibility of your semi-automatic thermal paper roll slitting rewinding machines?

Adjustability is part and parcel of Jota machinery. It is the responsibility of engineers to ensure that you get the exact product that you order.

With a full understanding of the nature of our business and the dire need for these machines by the public, our company ensures that we only deliver what will perfectly suit your needs without any inconvenience.

Except for flexibility, you can also customize your machine; how?

Very simple.

Just offer your particular need, unique application, and processes via a brief draft or request form. It is that simple.

The aftermath will be receiving the last thermal paper slitter rewinder proposal, ultimately contentment and satisfaction.

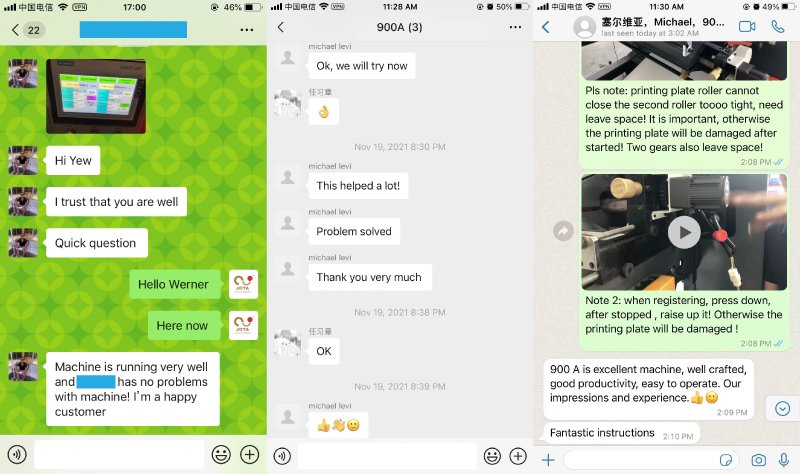

Does your technical team provide any services before or after delivery?

If you need our services, our team of experts will be there within the communicated time to take care of all your requests.

The work of the engineers sent to you will be to design and install the products.

Following the completion of installation, the engineers will educate your workers on the maintenance and operation of the machine.

Jota’s engineers take their time when teaching the products on all requirements; hence, they will ensure that your team will be experts on their own.

Customers are our priority; therefore, for excellent machine performance, our professionals extend their working time depending on the needs of our clients.

In conclusion, we present our genuine enthusiasm and the most energetic attitude so that all customers worldwide can fit in.

What is the quality of your machines?

When it comes to machine standards, Jota machinery is a very mature brand with over 20 years of experience in manufacturing semi-automatic thermal paper slitting rewinding machines and other different paper machines.

Therefore, we will make it our goal that you get maximum and executive check over.

We offer high-quality standards on advanced technology and the perfect service; we have, therefore, received an international certification in the field of producing high-quality equipment in firm accordance with ideal standards.

As a result, apart from ISO 9001 quality standard, we have also gotten awards one after the other due to the quality, serviceability, and response from our engineers.

Proof of our quality is in the evidence of the many different customers worldwide that have purchased and enjoyed the experience with the semi-auto thermal paper slitting machine.

Apart from our high-quality semi-automatic thermal paper roll slitter rewinder machine, what other products do Jota manufacture, feature, and use?

Our company produces almost all types of machines, from slitting rewinding machine to kraft paper tube making machine, fully automatic toilet tissue roll making machine, cardboard paper tube cutting machine and many more.

However, taking fully automatic toilet paper roll machine, for instance, It incorporates three significant machines in its production line, which are;

- Multi roll automatic packaging machine

- PLC intelligent touch automatic rewinder machine

- Fully automatic band saw paper cutting machine.

The machine has a core feeding section. Nevertheless, it can work with or without the body.

Raw inputs from the jumbo roll after edge or full embossing, later perforation, end cutting, and finally spraying the tail with glue to become a log.

Finally, it can function together with packing and cutting machines to become a finished product.

PLC curbs typically the machine. And since the entire process is automatic, people usually operate it via the touch screen because it is straightforward.

All these denote that our devices can work for anyone and anywhere. According to Jota machinery engineers, some of its features are as follows:

- Safe and ease in operation

- The distance for perforation is convertible enough to meet any length required.

- It maintains low noise, high precision spiral knives, and apparent perforation.

- Automatic moving of the log after winding, feeding core system automatically, rewinding the record again.

- Since the machine is used to make toilet paper rolls, the entire construction is wall-shaped, enabling the engine to run with no noise and at a stable high speed.

- It contains three paper strands: a pneumatic lift system with broad driving flat belts. The advantage of this is that every jumbo roll will be independently adjusted.

- Acquire international state-of-the-art PLC programmable and controlling approach, man-machine interface functionality, and finally show paramedic fault or data set on the screen.

These great qualities are for just a single semi-auto thermal roll slitting rewinding satellite product by Jota.

What are the returns of having a Semi-automatic paper roll slitting rewinder machine?

Aside from the numerous success stories, we have had in the recent past, our thermal paper slitting rewinding machine, in general, has got relatively unthinkable returns, a statement that shows profits are guaranteed.

And the main reason why the Jota Machinery has gotten into everybody is that we try to think of any potential problem you may experience. Then get into your shoes before coming out with the solution of going for a semi-automatic thermal paper slitter rewinder.

In short, one primary reason why you are most likely to benefit from our product is because of the vast knowledge and experience we have with the machine.

We know almost every loophole that thermal paper roll slitting machines may have, and for that reason, we create just the perfect problem-solver before you even notice the issue for you and your benefit.

One of the best things about Jota Machinery is that, not only do they sell you their high-quality products and teach you how to handle every part of the machine, they are also always ready and willing to walk with you in every step you take in your thermal paper slitting rewinding machine.

We recommend the best tips on what to and not to do, besides advising on the exemplary practices with the definitive objective that you fully benefit from our product.

Why choose Jota Machinery?

With over 12000 clients worldwide, we are an integrated trade company of diligent teams and professionals who employ cutting-edge technology to ensure that you get the best and high-quality product.

Our engineers are more than willing to travel thousands of miles to solve your mechanical problems wherever you may be.

We are based on an extraordinarily error-free slitter rewinder, under design by CNC and CTO and an assembly execution by an expert electrician when it comes to production.

Jota can comfortably supply you with 30 sets of slitter rewinders every month at a mature, sufficient, supporting, and supply chain artistry on a single contact.

When it comes to lead time, our global shipping for products is possible all the time. That is because we own a CNC business unit adjoined by three others under our cover, plus the element of our is very timely.

The history of our quality dates back ten years ago with a strong background of marketing campaigns and maintained good relationships with high-quality raw material suppliers.

And by any chance that you should break any of our product’s spare parts within the first year of purchase, you are guaranteed one at no cost attached to you.

Other than the free spare part, our prices are very pocket friendly.

And since Jota’s objective is a win-win exchange, we will do everything under our ability to make sure that you have a competitive advantage in profit even as you make some excellent interest.