Peru client Mr. M firstly contacted us on 14 Jul 2019, he sent an inquiry about thermal paper roll making machine to us that day.

In his inquiry, he described his requirements for thermal paper roll making machine:

Our company is based in Lima Peru and we are interested to buy one slitter rewinder machine for making ATM rolls and small thermal paper rolls, this machine should have 900mm width, max unwind diameter 1000mm, max rewind diameter 200mm and Voltage 220V three phases.

Mr. M’s inquiry

Based on these requirements, we recommended our JT-SLT-900 thermal paper roll making machine to Mr. M, because JT-SLT-900 is the best-selling model, it has many amazing features, these features are highly attractive to many giant clients, such as K.M.S from Egypt.

Egypt big client K.M.S

Speaking of JT-SLT-900, there are several important selling points deeply attract Mr. M’s attention.

First of all, its unwinding width is up to 900mm, unwinding diameter supports Max. 1000mm, rewinding diameter can reach 200mm after customization, 3 phase 220V voltage also could be easily realized.

That means, Mr M’s basic requirements could be easily met. Mr. M was quite satisfied, from the begining.

Then we made a video call with Mr. M, our engineer lively broadcast the machine operation to him. When our engineer was operating thermal paper roll making machine, our sales stood by our engineer introducing JT-SLT-900 in detail, from jumbo roll unwinding to waste removal.

So Mr. M got a comprehensive understanding of our JT-SLT-900 thermal paper roll making machine. What’s more, our sales led him visiting our factory and CNC center through mobile camera. It greatly increased Mr. M’s trust in us.

In the next communication, Mr. M listed many more questions, for example:

How is the system for printing end mark? It uses special ink?

Printing end mark is realized by ink wheel, it uses water-based ink, not special ink.

8 sets ink wheel

Water-based ink

How many spare parts include the machine as shafts, knifes, ink wheels, etc?

Spare Parts List

How many knives do you include in the machine?

16 Sets Rotary Knife

We answered Mr M’s questions patiently 1 by 1.

Finally, after 7 months communication, Mr. M paid deposit to buy our JT-SLT-900 thermal paper roll making machine in Feb 2020. And we made a video call on 1 Apr, 2020, he requested us to lively broadcast machine testing.

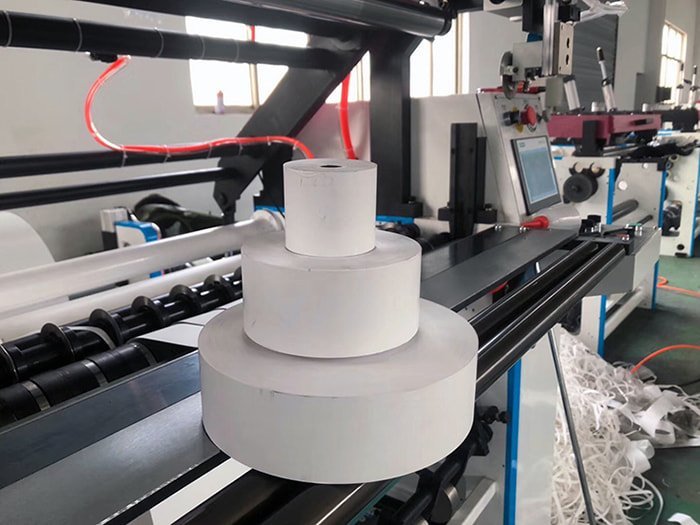

On 1 Apr, 2020, we told our engineer winding thermal paper small roll to 200mm diameter, final effect is shown in following photo and test video:

Final Winding Effect of 200mm Diameter Thermal Paper Roll

Mr. M watched the whole winding process via video call. After we hung up the video call, Mr. M sent us a message, this message really inspired our hearts, and made us feel that all our efforts and dedication are worthwhile.

Mr. M says, Jota thermal paper roll making machine looks amazing:

Rose to Mr. M

Thanks for Mr. M’s choice and trust, after he receive the machine, we will put our heart into after-sale service for him.

Please check following JT-SLT-900 thermal paper roll making machine presentation video for reference: