Carbon Fiber Preform - An excellent Composite Material for Aersopace

- Thermoset/thermoplastic prepreg manufacturing

- Own professional engineering team

- Supporting CNC machining center

- High-quality components at a glance

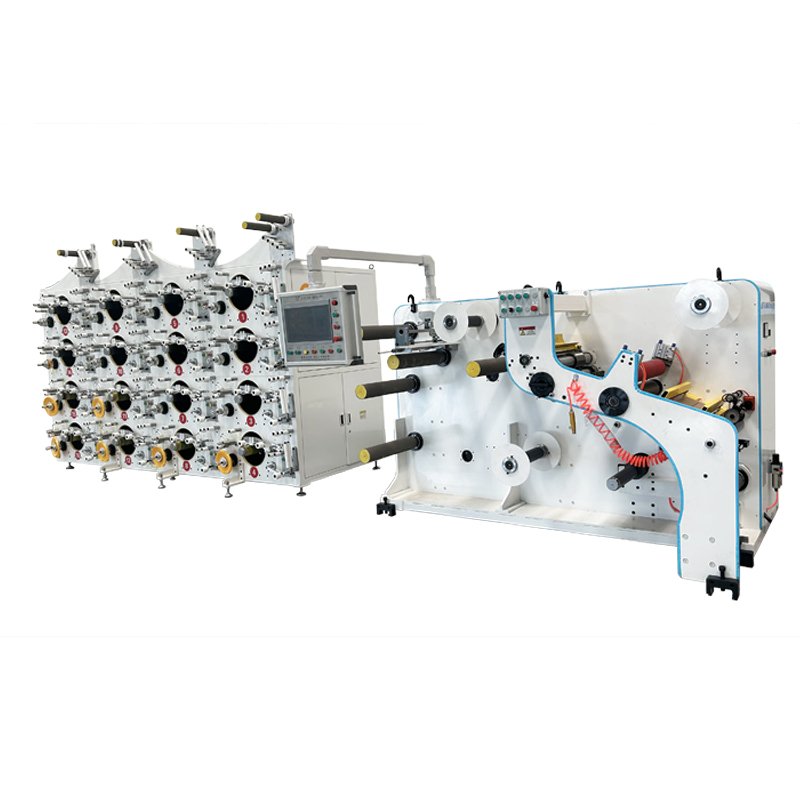

Jota CFRP CFRTP Hot Melt Prepreg Machine

Our Jota CFRP CFRTP prepreg manufacturing machines are ideal machines for CFRP CFRTP prepreg production.

CFRP and CFRTP prepregs are essential raw materials for the production of high-performance carbon fiber and glass fiber composite materials.

If you are looking for prepreg machines, please send us an inquiry on this website.

CFRP CFRTP Prepreg Conversation

Jota Machinery: Your Reliable CFRTP CFRP Prepreg Machine Manufacturer in China

Jota is the original CFRTP CFRP prepreg machine manufacturer here in China.

With our own factory and CNC center, equipment quality could be effectively guaranteed.

Please send us an inquiry to make a WhatsApp video call, let’s show you our real-time factory and CNC center.

Jota CNC Center

Machining Material

- Visible high-quality components.

- Famous brands such as Siemens, Yaskawa, Delta, Schneider, Mitsubishi.

- Self-supporting CNC processed sheet metal, precision parts.

- Assembly raw materials provided by long-term cooperation suppliers.

Installation and operation user manual, wire connection diagram, tension controller guide.

Installation and operation video tutorial.

One-on-one remote video call assistance.

On-site installation and operation guidance.

- Focus Factory

- Dear Customer

- Professional Team

Around 30-45 days, mainly depends on machine type.

Sure, it is our honor to work for you.

We will offer you some parts as backup, in case any part is broken within one year, we will sent you for free.

Sure, if we have client in your country, we will offer.

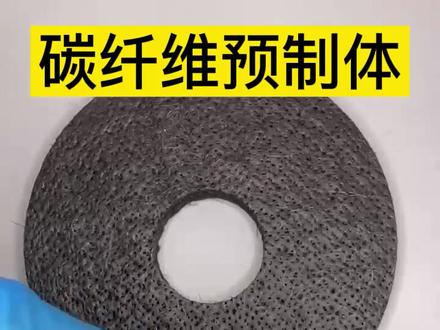

Carbon Fiber Preform: The Skeleton of Reinforced Carbon-Carbon Composite Material

Carbon fiber preform is the most basic reinforcing phase and the skeleton of C/C composite materials.

Today Jota Machinery will introduce the carbon fiber prefrom or C/C composite detailed from below chapter.

Since carbon fiber has a high modulus, is not resistant to bending, has a smooth surface and poor cohesiveness, and is easily damaged during the needle punching process, many needle punched preforms are made of pre-oxidized carbon fiber.

However, during the subsequent carbonization process, this type of needle-punched preform is prone to severe delamination deformation due to the inability to be drafted, with a mass loss of about 50% and a volume shrinkage of about 15%.

Therefore, it is highly difficult to achieve technical realization while retaining the performance of carbon fiber to the greatest extent while being woven.

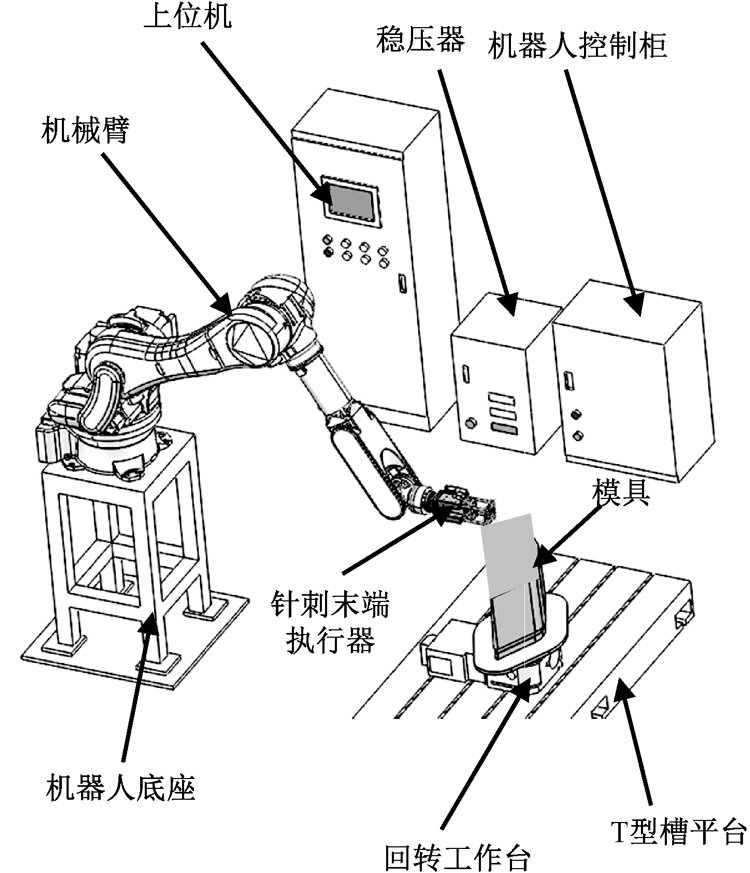

At present, needle punching, and three-dimensional weaving are the two mainstream prefabricated structures.

The former is mostly used for brake discs, and the latter is mostly used for aerospace components.

Carbon/ceramic composite materials have excellent performance and broad application prospects in the field of braking.

Brake materials for modern transportation vehicles such as airplanes, automobiles and high-speed trains have experienced development from cast iron, synthetic materials, powder metallurgy materials to carbon/carbon composite materials and carbon/ceramic composite materials.

Carbon/ceramic composite brake material is a brake material that introduces silicon carbide (SiC) ceramic hard material with excellent anti-oxidation properties as the matrix based on carbon/carbon composite brake material.

It maintains the characteristics of carbon/carbon composite brake the advantages of low material density and high temperature resistance also overcome the shortcomings of carbon/carbon brake materials such as low static friction coefficient, large wet attenuation, insufficient friction life and poor environmental adaptability.

Compared with traditional materials such as cast iron and powder metallurgy, carbon/ceramic composite materials, as friction braking materials with better braking performance and lighter weight, are expected to have broad market applications in the new round of new energy vehicle upgrades. prospect.

The development history of C/C composite

Since their invention in the 1960s, carbon/carbon composite materials have attracted great attention in the military, aerospace, and nuclear energy industries.

In the early stage, the manufacturing process of carbon/carbon composite materials was complicated, technically difficult, and the preparation process was long.

The cost of product preparation has been high for a long time.

Its use has been limited to some parts with harsh working conditions, as well as aerospace and other fields where other materials cannot be substituted.

At present, the focus of research on carbon/carbon composite materials is mainly focused on low-cost preparation, oxidation resistance, and diversification of properties and structures.

Among them, high-performance, low-cost carbon/carbon composite material preparation technology is the focus of research.

Chemical vapor deposition is the preferred method for preparing high-performance carbon/carbon composite materials and is widely used in the industrial production of carbon/carbon composite products.

However, this technology requires a long process time and therefore has high production costs. Improving the production process of carbon/carbon composite materials and developing low-cost, high-performance, large-sized, and complex-structured carbon/carbon composite materials are the key to promoting the industrial application of this material and are the main development of carbon/carbon composite materials at present.

The advantage of C/C composite

Carbon-carbon composite materials are a type of composite materials with carbon fiber reinforced carbon matrix.

They are characterized by high fracture toughness and good corrosion resistance and friction resistance.

Carbon/charcoal thermal field material products for photovoltaics have undergone high-temperature heat treatment at 1800℃-2000℃ and have good thermal shock resistance.

Compared with graphite, they have better performance, longer life, higher overall cost-effectiveness, and reduce the need to replace parts. times, thereby improving equipment utilization and reducing maintenance costs.

It can be made thinner, so existing equipment can be used to produce single crystal products with larger diameters, saving investment costs in new equipment.

High safety, not prone to cracks under repeated high temperature thermal shock.

Carbon composite materials have structural designability.

Carbon thermal field material products of different sizes and shapes can be prepared through prefabricated structure design and densification process.

Graphite requires the preparation of a solid blank first, and then mechanical processing to form the final product.

Therefore, compared with graphite, carbon-carbon composite materials have obvious advantages because there is no waste of leftover materials while carbon-carbon composite materials have functional designability.

By preparing carbon/carbon thermal field material products with different densities of high, medium and low.

It is used to match the different functional requirements of crystalline silicon growth such as heating, insulation, and load-bearing.

This feature can effectively reduce the energy consumption of single crystal silicon production.

The carbon-carbon composite manufacturing process

Strictly speaking, there are two types of carbon-carbon composite materials.

One is carbon fiber reinforced carbon matrix composite material, which is carbon-carbon composite material, and the other is carbon fiber reinforced carbon and silicon carbide matrix composite material, which is carbon/carbon-silicon carbide composite material.

The former is written as C/C, and the latter is written as C/C-SiC.

In fact, C/C-SiC composite materials are based on C/C and introduce SiC components through the siliconization process to improve the friction coefficient and make C/C have a certain antioxidant ability.

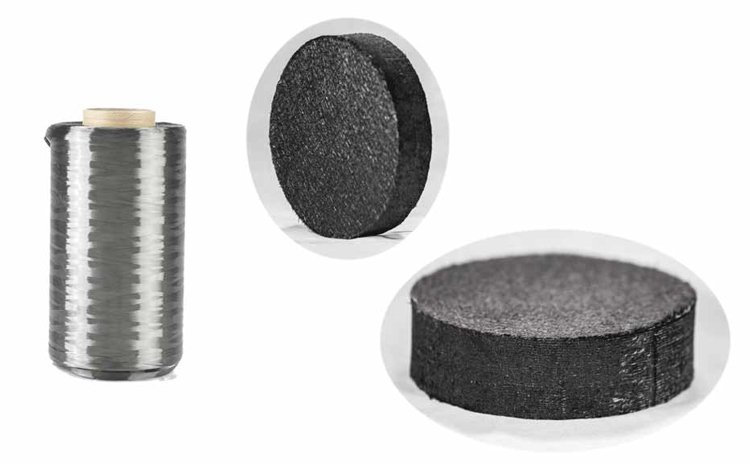

Three types of carbon fiber preform.

To make C/C composite materials, carbon fibers must first be woven into a prefabricated body, and then a carbon matrix is introduced inside the prefabricated body.

At present, the main preforms are mainly divided into three categories, short fiber molded preforms, carbon cloth laminated preforms, and needle punched preforms.

Short fiber molded preform is to mix short carbon fibers with a certain amount of resin and then mold them, which is like our CFRP process.

The fiber directions of this kind of prefabricated body are relatively chaotic and basically isotropic.

Carbon fiber fabric or cloth laminated prefabricated bodies mainly use unidirectional cloth or woven cloth, which are laid out layer by layer to form a prefabricated body.

This kind of prefabricated body is layered and has relatively strong mechanical properties within each layer, but it is easy to delaminate between layers.

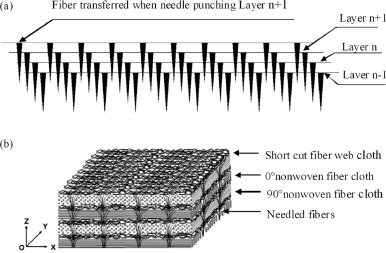

Needle-punched preforms mainly comb carbon fibers into meshes in the X-Y plane, and then use a needle-punched plate to introduce fibers in the Z direction to form an overall felt.

The advantage of this kind of prefabricated body is that there are fibers in the three directions of XYZ, and the mechanical properties can be guaranteed.

Three preparation methods

There are three main methods for preparing C/C composite materials.

The so-called preparation is to introduce a carbon matrix into the prefabricated body.

According to the different forms of introduction, it is divided into three types. Because we have no way to make carbon into a liquid or solid state and add it to the prefabricated body, we can only use indirect methods, that is, using carbon-containing liquids and carbon-containing solids to introduce them into the prefabricated body, and then let the carbon-containing liquid and carbon-containing solids.

The carbon gas is cracked to produce solid carbon, forming a carbon matrix.

Therefore, the main methods include chemical vapor infiltration CVI, precursor cracking PIP, and reactive infiltration RMI.

Chemical vapor infiltration (CVI) is to pass carbon-containing gas into the prefabricated body, and then crack the gas into a solid carbon matrix through high-temperature cracking.

The carbon-carbon composite materials produced by this method have high density, but the process cycle is relatively long, and the equipment and cost are relatively expensive.

Precursor cracking PIP is to add carbon-containing resin to the preform, and then form a solid carbon matrix through high-temperature cracking.

The density of carbon-carbon composite materials in this process is low and requires continuous impregnation-carbonization cycles for many times to reach a certain density.

Therefore, PIP is usually mixed with the CVI process.

Reaction infiltration RMI is mainly used when introducing SiC matrix into C/C composite materials.

It mainly means that the Si element is melted and impregnated into the open pores of the C/C composite material, and silicon carbide is generated through the reaction of silicon and carbon.

In the form of introducing SiC components into C/C composite materials.

The application of C/C composite

As an excellent thermal structure and functional integrated engineering material, carbon/carbon composite materials have made great progress in the military industry since their birth.

The most important use is in the manufacture of missile warhead components.

Due to its high temperature resistance and good friction, it has been widely used in solid rocket motor nozzles, space shuttle structural components, aircraft braking devices, thermal components and mechanical fasteners, heat exchangers, hot end components of aerospace engines, etc.

Currently, solid rocket motor nozzles and brake discs are the two main application areas of carbon/carbon composite materials.

More than half of these carbon/carbon composites are used in aircraft brakes.

Aircraft brake discs made of carbon/carbon composite materials are light in weight, have high temperature resistance, and have a specific heat capacity 2.5 times higher than steel.

Compared with metal brake materials, they can save 40% of the structural weight, increase their service life by 5 to 7 times, and brake torque. Smooth and low noise when braking.

Therefore, the advent of carbon brake discs is considered a major technological advancement in the history of brake material development.

In 2001, Porsche applied the carbon/ceramic braking system to a car for the first time, and it was installed on the 911 GT2 sports car.

The 911 C4S has been available as an option since November 2002.

Other well-known brands of cars have also begun to adopt this innovative braking technology to improve vehicle safety and pedal comfort.

However, due to the high cost of carbon/ceramic, the price is extremely expensive.

For example, the price of carbon/ceramic brake discs provided by Brembo, a world-renowned brake system manufacturer, ranges from 120,000 to 160,000 yuan.

Previously, its application was limited to some high-end sports cars or modified car field.

With the rapid development of new energy vehicles, carbon/ceramics is expected to usher in new opportunities.

Lightweighting can effectively improve the vehicle’s handling and power, improve the vehicle’s acceleration performance, and shorten the braking distance.

Although electric vehicles do not have traditional engines and gearboxes, the power battery pack they carry accounts for a large proportion of the vehicle’s mass.

If electric vehicles want to improve their performance and surpass that of fuel vehicles, they must develop lightweight structures.

When a pure electric passenger car loses 10% of its weight, power consumption will drop by 5.5% and its cruising range will also increase by 5.5%.

Carbon/ceramic brake discs can effectively reduce unsprung mass and provide better control and braking experience.

Tesla will launch a carbon/ceramic brake package option for the Model S Plaid model in mid-2022, priced at up to $20,000.

As independent brands intensively launch high-end electric models, carbon/ceramic brake discs are expected to become a differentiated selling point.

Moreover, domestic carbon/ceramic brake discs currently sell for about 10,000 yuan per bicycle, which can provide cost-effective products at a low price and benchmark the configurations of foreign luxury models.

Currently, GAC, BYD and Xpeng are developing carbon/ceramic brake discs for new models.

It is expected that several domestic models equipped with carbon/ceramic brake products will be launched in 2023.

With the decline in preparation costs and improvement in performance, carbon/ceramic brake discs are expected to be the first to be used in C-class luxury cars, and gradually replace cast iron discs in B-class mid- to high-end models.

If you want to know more information about carbon fiber preform and reinforced carbon-carbon composite material product then don’t hesiated to contact Jota Machinery.

We will give you sincerly one-stop sevice.