900-1400mm Width Fully Automatic Thermal Paper Slitting Machine

- Driven by 7 servo motors, whole process is high precision operation

- Easy operation and automatic EPC

- 6.35mm & 12.7mm slitting width can be easily realized

- Online peeling device for thermoplastic composite material

- Two sets of waste edge rewinding wheels

- The transmission station for cutting developed by Jota Machinery

- Specification

- Video

| Parameters | |

| Item | JT-SLT-320X Carbon Fiber UD Tape Slitter Rewinder |

| Max. Unwinding Width | 320mm |

| Max Unwinding Diameter | 650mm |

| Max Rewinding Diameter | 500mm |

| Min Slitting Width | 5-320mm |

| Rewinding Shaft | 2 PCS Water Cooling Differential Friction Shaft |

| Unwinding Shaft | 3″ (76mm) air expanding shaft |

| Speed | 50m/min |

| Servo Motor | 7 Sets |

| Tension Control | PLC Control The Tension |

| Rated Power | 11Kw |

| Dimension | 3300MM*1700MM*2000MM |

| Voltage | 380V/50Hz |

| Weight | 3000 KG |

SPECIFICATIONS | |

| JT-SLT-320X Carbon fiber UD tape slitter rewinder is especially design for slitting CFRTP, CFRP, FRP Prepreg, Thermosetting Tapes, Etc. | |

|

Unwinding Section | Two sets unwinding . Upper is for jumbo roll unwinding and lower is the stripped waste collection shaft |

| Both shaft is Φ 3” (76mm), 6″ is optional | |

| 10kg/m2 electromagnetic brake from Taiwan. | |

| Photoelectric sensor web guiding. | |

| EPC Unit | High frequency ultrasonic EPC |

| The EPC motor is a high-speed servo motor, which is efficient and sensitive. | |

| Slitting Section | The machine equips disc blade for slitting and min slit width can reach to 5mm |

| The shaft equipped safety cover | |

|

Tranmission unit | The transfer roller adopts a special wear-resistant and anti-adhesive Teflon roller, and the end of each roller is marked with a sign of the direction of rotation |

| The transmission roller has undergone dynamic and static balance processing, quantity: 5 | |

| Two set waste edge wheels | |

|

Rewinding Unit | 3-inch water cooling differential shaft |

| One for each of the upper and lower | |

| Two set pressure arm for rewinding | |

| Waste Removal | Two sets wheel for rewinding waste edge |

|

Saftey Cover | Aiming at the conductivity of carbon fiber, the machine is equipped with electrostatic isolation protection |

| The whole machine adopts a closed design, covering an area of about 6*3.5 *2.2m | |

| The electrical appliances are fully enclosed design, and the sealing strip realizes the finishing and sealing of the control cabinet | |

| The ventilation fan is equipped with a sponge filter | |

| The whole machine is connected ground wire, and the dangerous parts have safety signs | |

900-1400mm Width Fully Automatic Thermal Paper Slitting Machine

After Jota Machinery launched the semi-automatic thermal paper production line, we successively launched the fully automatic thermal paper slitting machine. As of 2022, our automatic thermal paper slitting machine has joined the customer’s production queue, and its reputation is also very good

Here we have to talk about our Turkish customers who purchased a fully automatic thermal paper slitting machine. Before delivery, we taught customers how to wire (including aviation plugs, conduit machines, conveyor lines, and thermal paper packaging machines), and through online video communication, customers have successfully operated this fully automatic thermal paper with a printing unit.

Fully automatic thermal paper slitting machine as a best-selling slitting machine is it because of a fully automatic function? Then you are wrong. Let me give you a detailed introduction to our fully automatic thermal paper slitting machine from the structure of our machine.

- Unwinding section

- Tension Section

- Slitting Section

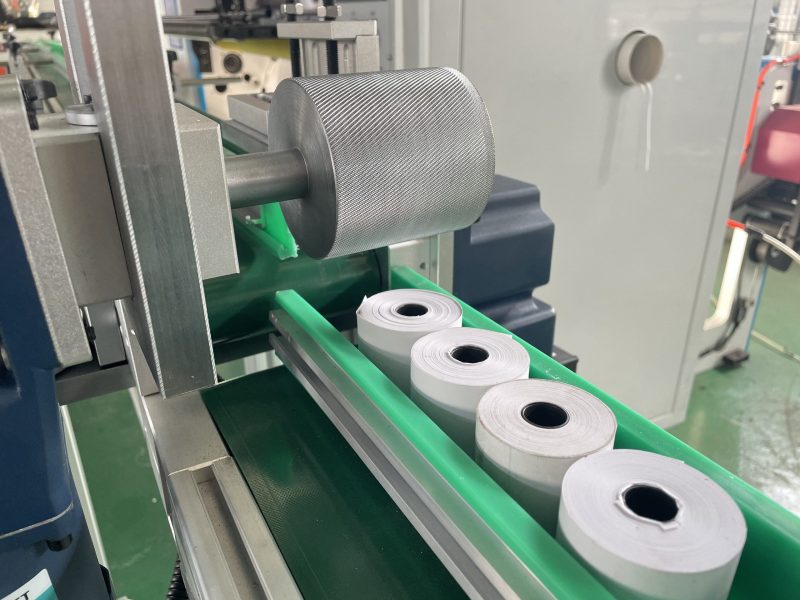

- Rewinding Section

- Control Section

- Conveyor section

- Packing Line

Unwinding section

The fully automatic thermal paper slitting machine adopts a unique shaftless unwinding structure, which is very suitable for the slitting machine of large thermal paper master rolls.

In addition, the feeding method adopts the hydraulic Loading method. The combination of shaftless unwinding and hydraulic feeding makes feeding easier

| Max Unwinding Width | 1400mm |

| Max Unwinding Diameter | 1200mm |

| Unwinding Type | Shaftless Design |

| Chuck Size | 3-inch |

Tension Section

Compared with our traditional 900mm thermal paper slitting machine, this equipment uses an automatic tension controller, which is easier to operate and more accurate.

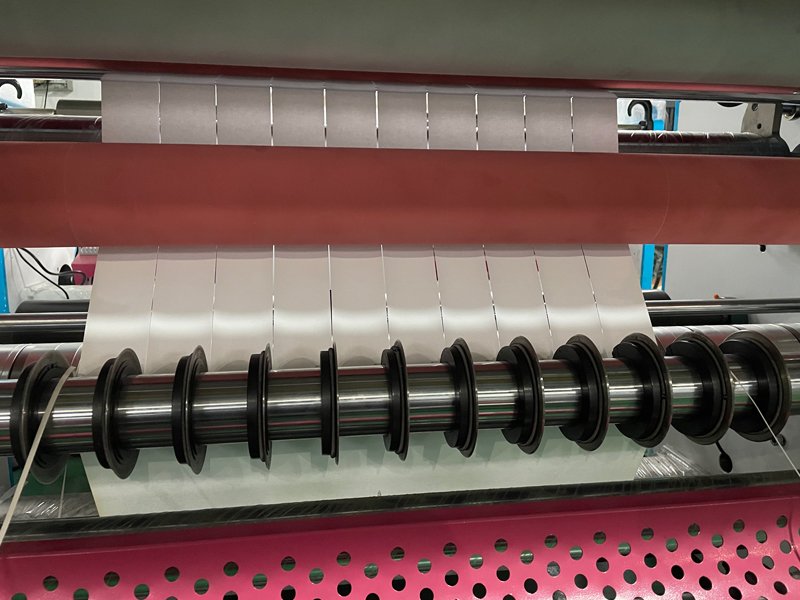

Slitting Section

A fully automatic thermal paper slitting machine uses an around/disc blade for cutting paper. Frequently used 79mm and 56mm width can easily get from slitting machine.

| Slitting Blade | Round Blade |

| Min Slitting Width | 15mm |

The upper blade shaft consists of slitting blades, holder, and spring and the lower blade shaft consists of aluminum spacers and a lower blade. You can change the slitting width by adding or removing the spacer.

Below is the video of how to change the slitting width for your reference